Introduction

In the ever-evolving landscape of construction, prefabricated building components have emerged as a game-changer, revolutionizing how we think about design and assembly. These components are manufactured off-site and then transported to the construction site for quick assembly, allowing for greater efficiency and flexibility. With companies like PreFab Inc. leading the charge, the industry is witnessing a shift towards innovative building practices that promise not just speed but also sustainability.

What Are Prefabricated Building Components?

Prefabricated building components refer to elements of a structure that are constructed in a factory setting before being transported to the final site for assembly. This includes wall panels, modular units, and roof systems that are pre-made to fit specific designs and standards. By utilizing prefabrication techniques, builders can streamline their processes while maintaining high-quality standards.

Benefits of Using Prefabricated Components

The benefits of using prefabricated building components are numerous and compelling. First and foremost, these components significantly reduce construction time by allowing multiple parts of a project to be built simultaneously in different locations. Additionally, they minimize waste since materials can be optimized during production, leading to both cost savings and environmental benefits—something PreFab Inc. is particularly passionate about.

How Prefabrication is Changing Construction

Prefabrication is changing construction by introducing new efficiencies that traditional methods struggle to match. This approach not only speeds up project timelines but also enhances quality control through factory manufacturing processes that reduce human error on-site. As more companies embrace this innovative method, we’re likely to see an industry-wide transformation that prioritizes sustainability and efficiency in every build.

Understanding Prefabrication

Prefabrication is a transformative approach to construction that has evolved significantly over the years. By assembling building components off-site and transporting them to the construction location, prefabricated building components streamline the entire process, reducing time and labor costs. This section will explore the historical evolution of these components, highlight key players in the industry, and discuss how PreFab Inc. is shaping modern construction.

Historical Evolution of Prefabricated Building Components

The concept of prefabricated building components isn't new; it dates back to ancient civilizations where modular designs were utilized for efficiency. However, it gained significant traction during the Industrial Revolution when mass production techniques allowed for standardized parts to be manufactured en masse. Fast forward to today, prefabrication has become a sophisticated field with advanced technologies like 3D printing and modular design further enhancing its potential.

In post-World War II America, there was a surge in demand for quick housing solutions, leading to an increased interest in prefabricated structures. This period saw innovations such as flat-pack homes and panelized systems that could be easily transported and assembled on-site. Today’s advancements focus on sustainability and energy efficiency, ensuring that prefabricated building components not only meet structural needs but also environmental standards.

The evolution continues as architects and builders embrace digital tools like Building Information Modeling (BIM) to design complex structures with prefabricated elements seamlessly integrated into their plans. This historical journey highlights how far we've come in utilizing prefabrication as a viable alternative to traditional construction methods.

Key Players in the Prefabrication Industry

The landscape of prefabrication is populated by various key players who contribute significantly to its growth and innovation. Major manufacturers of prefabricated building components include companies like Katerra, Factory OS, and Modulus Homes, each bringing unique approaches to modular construction techniques. These companies are not just pushing boundaries but also setting industry standards for quality and efficiency.

In addition to manufacturers, architectural firms are increasingly recognizing the advantages of integrating prefabricated elements into their designs—creating partnerships that enhance both aesthetics and functionality. Firms like Gensler have been at the forefront of this movement by advocating for sustainable practices while leveraging advanced technologies in their projects.

PreFab Inc., positioned among these industry leaders, plays an essential role by focusing on creating high-quality prefabricated building components tailored specifically for modern construction needs. Their commitment ensures that clients receive innovative solutions without compromising quality or sustainability.

The Role of PreFab Inc. in Modern Construction

PreFab Inc. stands out as a frontrunner in revolutionizing how we think about construction through its extensive range of prefabricated building components designed for versatility and durability. The company prides itself on being at the intersection of technology and craftsmanship—ensuring that every component produced meets rigorous standards while also being environmentally conscious.

By utilizing advanced manufacturing techniques combined with skilled craftsmanship, PreFab Inc.’s products significantly reduce waste during both production and assembly phases—a critical factor considering today's emphasis on sustainable development practices within the industry. Their focus not only addresses immediate project needs but also aligns with long-term goals toward reducing carbon footprints associated with traditional building methods.

Moreover, PreFab Inc.'s collaborative approach allows them to work closely with architects and contractors throughout all stages—from design conception through final assembly—ensuring seamless integration into various projects across different sectors including residential homes, commercial spaces, and even public infrastructure developments.

Types of Prefabricated Components

Prefabricated building components come in various forms, each tailored to meet specific construction needs while enhancing efficiency and sustainability. Understanding the different types of prefabricated components is crucial for anyone looking to streamline their construction projects. In this section, we’ll delve into three primary categories: wall panels and structural systems, modular building units, and prefabricated roof systems.

Wall Panels and Structural Systems

Wall panels are among the most commonly used prefabricated building components in modern construction. These panels can be manufactured off-site and then transported to the job site for quick assembly, significantly reducing labor costs and time on site. PreFab Inc. specializes in creating high-quality wall panels that not only meet structural requirements but also enhance energy efficiency through superior insulation properties.

Structural systems made from prefabricated components are designed to provide robust support for buildings while minimizing waste during the construction process. By utilizing advanced manufacturing techniques, these systems ensure consistent quality control and reduce the likelihood of defects that can occur with traditional methods. When you choose PreFab Inc., you're investing in innovative solutions that elevate your project’s performance right from the foundation up.

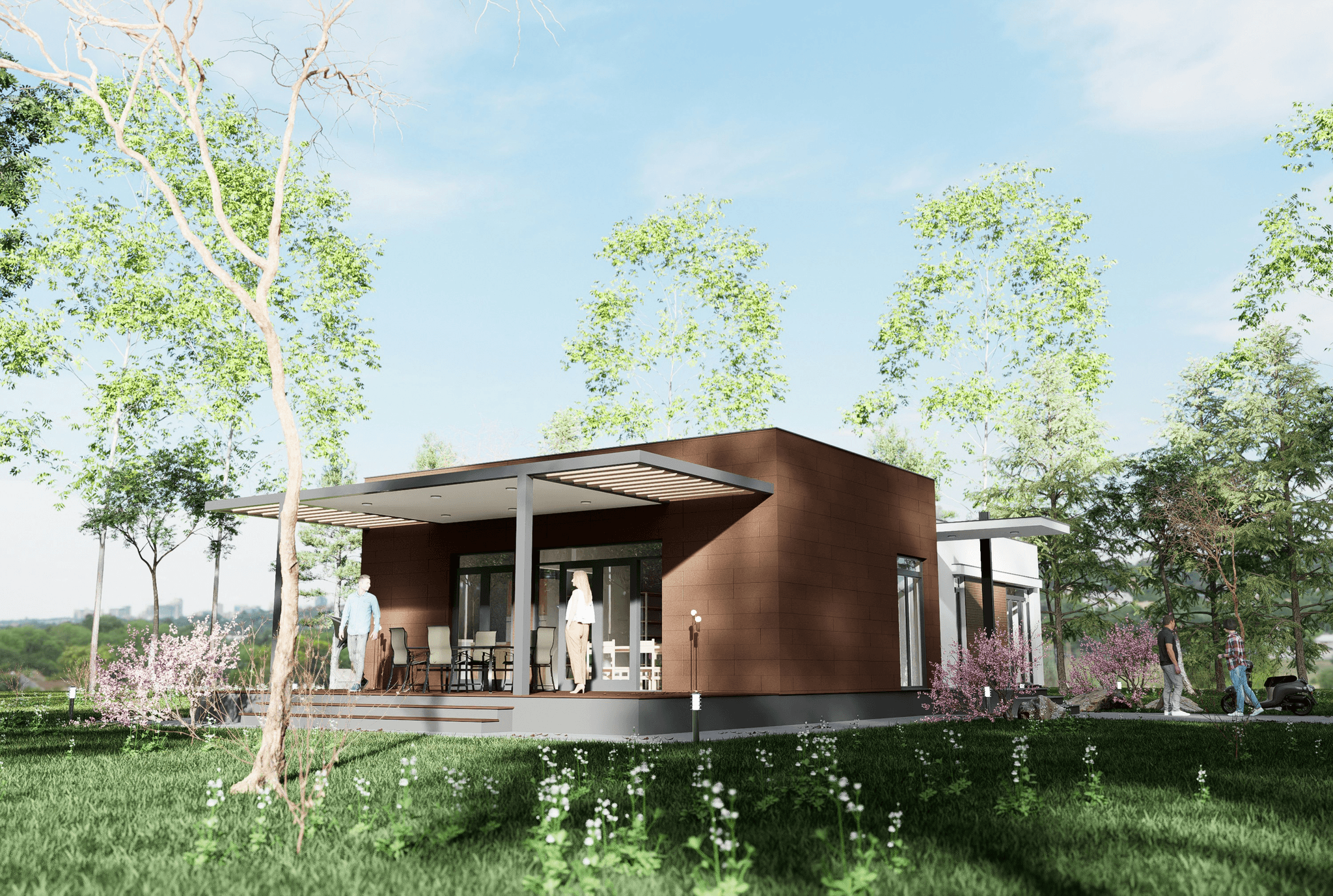

Modular Building Units

Modular building units represent a revolutionary approach to constructing entire structures using prefabricated components. These units are pre-built sections of a building that can include everything from walls to plumbing fixtures, allowing for rapid deployment on-site with minimal disruption. PreFab Inc.’s modular solutions enable developers to create complex buildings quickly while maintaining high standards of quality.

The versatility of modular units makes them ideal for various applications, from residential homes to commercial space expansions. They can be easily customized based on client specifications or site conditions without compromising structural integrity or design aesthetics. With an increasing demand for sustainable practices in construction, opting for modular building units helps reduce overall carbon footprints by minimizing waste during production.

Prefabricated Roof Systems

When it comes to completing a structure efficiently, prefabricated roof systems play an essential role among various prefabricated building components. These roofs are manufactured off-site and designed to fit seamlessly onto existing structures or new builds alike, ensuring swift installation without sacrificing durability or style. At PreFab Inc., our roof systems are engineered with materials that withstand diverse weather conditions while providing excellent insulation.

Prefabricated roof systems also offer significant advantages in terms of energy efficiency by allowing builders to incorporate advanced technologies such as solar panels directly into their designs at the factory level. This proactive approach not only saves time during installation but also enhances the long-term sustainability of buildings constructed with these innovative materials. As more architects and builders recognize these benefits, it's clear that prefabrication is reshaping how we think about roofing solutions.

Benefits of Prefabricated Building Components

The rise of prefabricated building components has ushered in a new era for construction, making projects more efficient and sustainable. These components offer numerous advantages that can significantly enhance the overall building process. From cost savings to improved quality control, prefabrication is redefining how we think about construction.

Cost-Effectiveness and Reduced Waste

One of the most compelling benefits of using prefabricated building components is their cost-effectiveness. By manufacturing these components in a controlled environment, companies like PreFab Inc. can minimize material waste and reduce labor costs associated with traditional construction methods. This not only leads to significant savings but also promotes sustainability by ensuring that fewer materials end up in landfills.

Moreover, reduced waste means that projects can stay within budget more easily, allowing builders to allocate funds to other essential areas without compromising quality. With streamlined processes and bulk purchasing of materials, the overall cost per unit decreases further, making prefabrication an attractive option for both residential and commercial projects. Ultimately, investing in prefabricated building components is a smart financial decision for developers looking to maximize their resources.

Speed of Construction and Project Timelines

Time is money in the construction world, and prefabricated building components are designed with speed in mind. The off-site fabrication process allows for simultaneous site preparation while components are being constructed elsewhere—meaning less downtime between phases of a project. PreFab Inc.’s innovative approach ensures that structures can be erected much faster than conventional methods allow.

This acceleration not only shortens project timelines but also enables quicker occupancy for clients eager to move into their new spaces or businesses looking to open their doors sooner. Faster completion times translate into lower financing costs and increased return on investment for developers who need to get their projects up and running quickly. In today’s fast-paced market, leveraging the speed advantage offered by prefabrication can be a game-changer.

Enhanced Quality Control in Manufacturing

Quality control is paramount when it comes to construction standards, and prefabricated building components excel in this area due to their factory-based production processes. With controlled environments free from weather-related disruptions or on-site errors, manufacturers like PreFab Inc. can ensure consistent quality across all units produced. This level of precision leads to fewer defects and enhanced durability compared to traditional methods where variability often occurs.

Additionally, rigorous testing protocols can be implemented during manufacturing stages—something that's harder to achieve on chaotic job sites filled with numerous variables affecting outcomes. As a result, clients receive high-quality structures that meet stringent safety regulations while maintaining aesthetic appeal over time. Enhanced quality control through prefabrication not only builds trust but also reinforces the value proposition for stakeholders involved.

Challenges in Prefabrication

While prefabricated building components offer several advantages, they are not without their challenges. Understanding these hurdles is crucial for stakeholders in the construction industry, including firms like PreFab Inc., which are leading the charge in modernizing building practices. Here, we delve into three primary challenges: transportation and logistics issues, site preparation and integration, and misconceptions about prefabricated structures.

Transportation and Logistics Issues

One of the most significant hurdles in utilizing prefabricated building components is transportation logistics. These components are often large and cumbersome, requiring specialized vehicles for safe transit to construction sites. Additionally, coordinating delivery schedules can be a logistical nightmare; delays can lead to increased costs and project timelines that spiral out of control.

Moreover, local regulations may complicate matters further by imposing restrictions on the size or type of vehicles allowed on certain roads or during specific hours. This means that companies like PreFab Inc. must carefully plan routes to ensure timely delivery while adhering to local laws. Ultimately, efficient transportation is vital for maintaining the cost-effectiveness that makes prefabrication so appealing.

Site Preparation and Integration

Another challenge lies in site preparation and the integration of prefabricated components with traditional construction methods. While these components can significantly speed up construction timelines, they still require a well-prepared site to ensure proper installation. This often involves extensive groundwork that must be completed before any prefabricated elements arrive on-site.

Furthermore, integrating these components with existing structures or systems can present difficulties if not managed correctly. For instance, ensuring that plumbing or electrical systems align perfectly with modular units requires meticulous planning and execution by skilled professionals from companies like PreFab Inc., who specialize in seamless integration processes.

Misconceptions About Prefabricated Structures

Misconceptions about prefabricated structures also pose considerable challenges in their adoption within the industry. Many people still associate prefabrication with lower quality or temporary solutions; however, this perception couldn’t be further from reality today. In fact, modern prefabricated building components undergo rigorous quality control processes that ensure durability and aesthetic appeal.

These misconceptions can deter potential clients from considering innovative solutions offered by firms like PreFab Inc., limiting their options for high-quality construction methods that could save time and money overall. Education plays a critical role here; as more people become aware of the benefits associated with modern prefab techniques, acceptance will likely grow.

Case Studies: Successful Prefabricated Projects

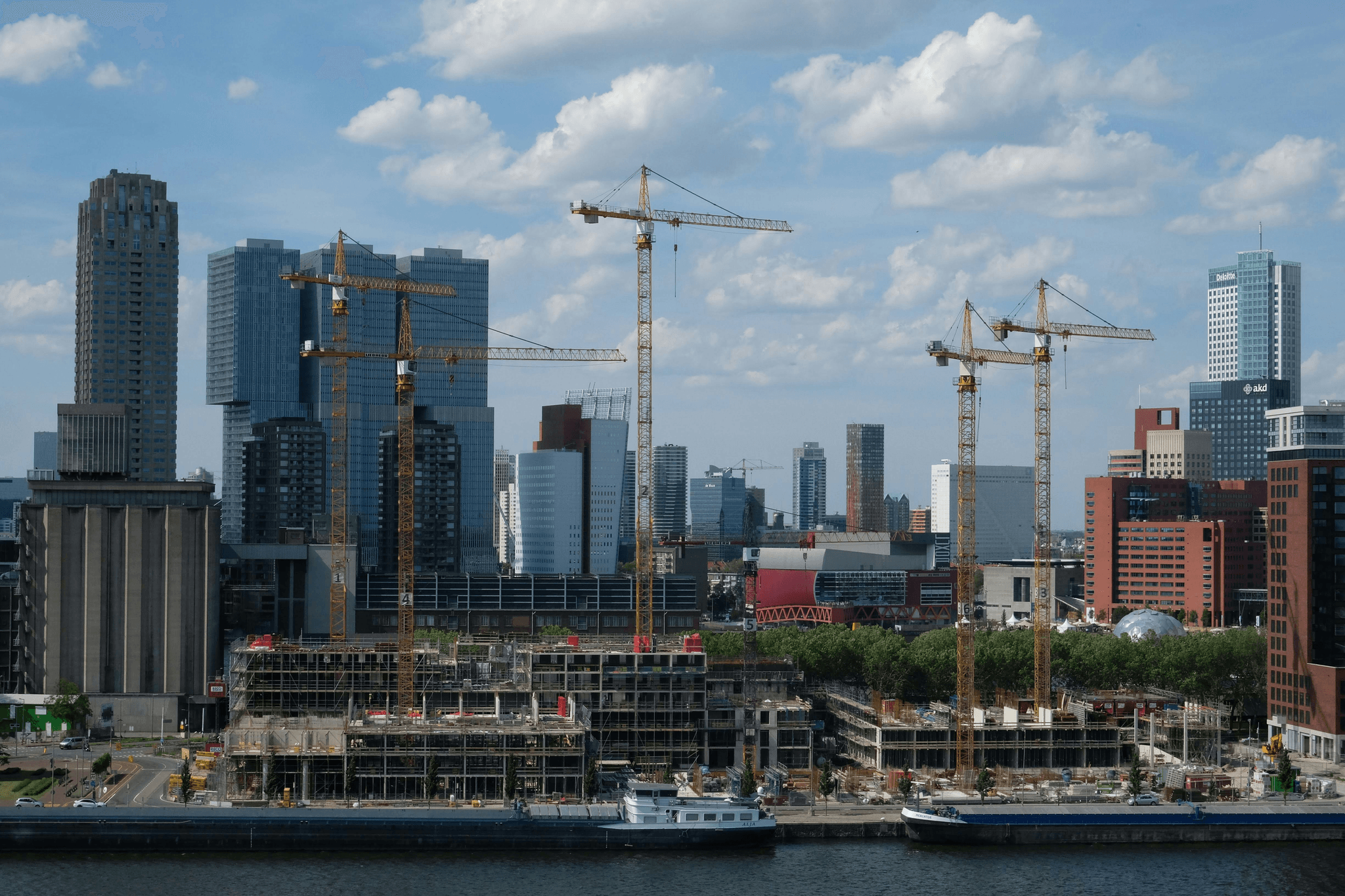

Prefabricated building components are making waves in the construction industry, and numerous case studies highlight their effectiveness. From innovative homes to large-scale commercial projects, these examples demonstrate how prefabrication can transform traditional building methods into more efficient and sustainable practices. Let’s dive into three notable cases that showcase the potential of prefabricated components.

The New London Architecture Prefab Home

The New London Architecture Prefab Home is a shining example of how prefabricated building components can redefine residential living. This project utilized modular wall panels and structural systems to create a home that is not only aesthetically pleasing but also energy-efficient. By employing prefabrication techniques, the builders reduced construction time significantly while maintaining high-quality standards.

Designed with sustainability in mind, this home features eco-friendly materials and energy-efficient systems, showcasing how modern architecture can harmoniously blend with environmental considerations. The use of prefabricated components allowed for quick assembly on-site, minimizing waste and disruption in the community. As a result, this project has become a model for future developments focusing on sustainability through prefabrication.

Walmart's Use of Prefabricated Components

Walmart has embraced prefabricated building components to enhance its store construction processes across the globe. By integrating modular building units into their design strategy, Walmart has streamlined its operations while reducing costs associated with traditional construction methods. This approach not only accelerates project timelines but also ensures consistent quality across various locations.

With an emphasis on efficiency, Walmart’s adoption of prefabrication exemplifies how large corporations can leverage modern construction techniques to meet consumer demands swiftly. The company has reported significant savings in both time and resources by utilizing prefabricated elements in their stores’ designs. Consequently, Walmart serves as a prime example of how embracing innovation can yield substantial benefits in retail development.

PreFab Inc.’s Role in Sustainable Developments

PreFab Inc., a leader in the production of prefabricated building components, plays an instrumental role in advancing sustainable development practices within the construction industry. By providing high-quality modular systems and wall panels crafted from eco-friendly materials, PreFab Inc. helps clients achieve their sustainability goals without compromising on design or functionality. Their commitment to reducing waste through efficient manufacturing processes aligns perfectly with contemporary environmental standards.

One noteworthy project involving PreFab Inc. included several residential developments where they supplied innovative roof systems and structural elements designed for optimal energy efficiency. These projects not only showcased the versatility of their prefabricated components but also highlighted how such solutions contribute positively to community aesthetics and environmental health alike. Through these initiatives, PreFab Inc.’s impact extends beyond mere construction; they are shaping a greener future for urban living.

Conclusion

In summary, prefabricated building components are not just a passing trend; they represent a significant shift in the construction industry. As technology advances and sustainability becomes a priority, these components will likely play an even larger role in future projects. Companies like PreFab Inc. are at the forefront of this transformation, continuously innovating to meet the demands of modern construction.

The Future of Prefabricated Building Components

The future of prefabricated building components is bright and full of potential. With increasing urbanization and the need for efficient housing solutions, these components offer a practical answer to pressing challenges in construction. Moreover, advancements in technology will enhance design flexibility and customization options, allowing for more creative applications of prefabrication.

Why Choose Prefabrication for Your Next Project

Choosing prefabrication for your next project can lead to significant advantages that traditional construction methods may struggle to match. Not only do prefabricated building components reduce waste and lower costs, but they also speed up project timelines without sacrificing quality. With PreFab Inc.'s expertise in this area, clients can rest assured that their projects will be completed efficiently and effectively.

Final Thoughts on Prefabricated Construction Trends

As we look toward the future, it’s clear that prefabricated construction trends are here to stay. The benefits of using prefabricated building components—such as cost savings, sustainability, and quality control—are compelling reasons for any builder or developer to consider them seriously. Embracing these innovations not only positions businesses at the cutting edge but also contributes positively to our environment by promoting sustainable practices.