- About PreFab

- …

- About PreFab

- About PreFab

- …

- About PreFab

Detachable Container House

Expert Modular Space Specialist: High-Performance Detachable Container Solutions for Global Projects

Sustainable & Rapidly Deployable

Detachable Container Housing

As a global specialist in modular space solutions, we excels in the strategic sourcing, customized engineering, and global distribution of high-performance detachable container houses. Our mission is to bridge the gap between complex architectural needs and efficient modular construction by providing rapidly deployable, cost-effective, and sustainable living and working environments.

Rather than being limited by a single production line, we leverage an integrated supply chain to ensure the highest standards of structural integrity and logistical efficiency. Our detachable units have become the gold standard for construction site housing, remote mining camps, and temporary medical facilities, backed by our commitment to rigorous quality inspection and end-to-end project management worldwide.

Product Overview: Detachable Container House

In the rapidly evolving world of modular construction, the detachable container house has emerged as a game-changer for businesses seeking flexible, high-quality, and cost-effective space solutions. But what exactly is it, and why is it replacing traditional prefab methods?

Defining the "Detachable" Innovation

A detachable container house (often referred to as a "bolt-up" or "knock-down" container) is a prefabricated modular building system where every single component—from the primary structural steel frame to the smallest wall cladding—is manufactured as an independent part.

Unlike a standard shipping container that is welded into a fixed box, a detachable unit is designed to be completely disassembled. This means the roof frame, floor frame, corner columns, and wall panels are all separate pieces that are bolted together on-site. This modularity is the core reason why it is the preferred choice for large-scale international projects.

How It Differs from Other Prefab Types

To understand the value of a detachable unit, it's essential to compare it with other modular options:

- Detachable vs. Shipping Containers: Shipping containers are heavy, expensive to modify, and costly to ship due to their fixed volume. Detachable houses are lightweight, purpose-built for living/working, and shipped in high-density bundles.

- Detachable vs. Flat-Pack Containers: In a "Flat-Pack," the roof and floor are usually pre-assembled at the factory. In a detachable house, the roof and floor are also broken down into individual beams and purlins. This allows for even more units to be loaded into a single shipping container, maximizing your logistics budget.

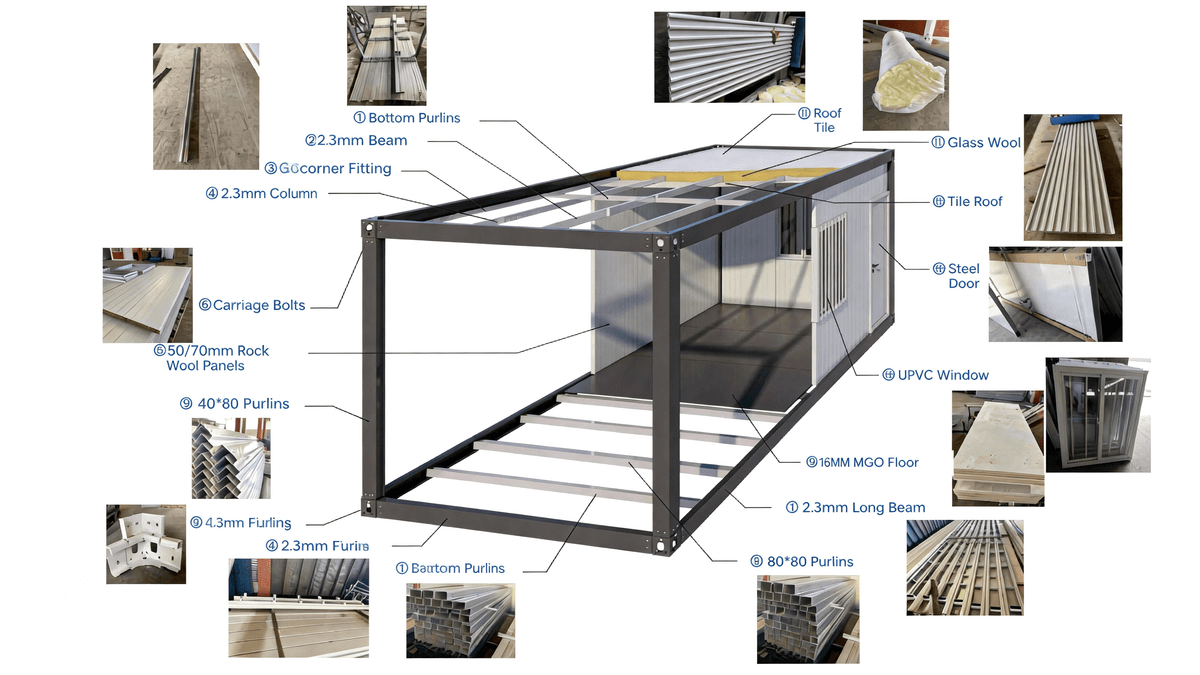

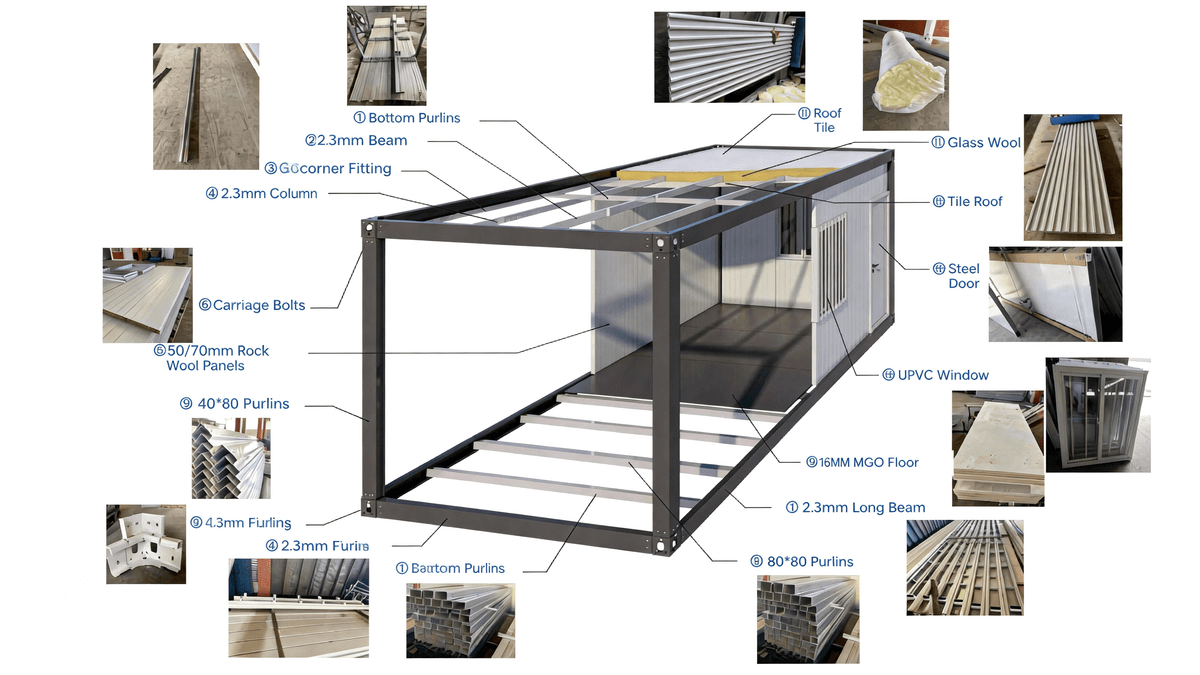

The Anatomy of a Detachable Container Unit

As a premier supplier, we ensure that every component of our detachable houses meets international structural standards. The system typically consists of:

- The Steel Skeleton: High-strength, galvanized Q235B steel. The galvanization process is crucial as it prevents rust and corrosion, especially in humid or coastal environments.

- The Enclosure System: High-density sandwich panels. Depending on the project requirements, these can be customized using Rock Wool (for fire safety), EPS (for cost-efficiency), or PU (for maximum thermal insulation).

- The Drainage Logic: One of the most common questions we get is about water leakage. Our detachable units feature an integrated gutter system. Rainwater flows from the roof into hidden gutters within the roof beams and is discharged through downspouts hidden inside the corner columns.

- The Foundation Flexibility: Because these units are significantly lighter than concrete buildings, they require minimal foundation work. They can be placed on concrete piers, leveled ground, or even a simple steel chassis.

Why This System is Scaling Globally

The surge in demand for detachable modular units is driven by three main factors:

- Extreme Portability: Because the house can be "knocked down" into a flat bundle, it can be transported to remote areas—such as mountain mines or dense forest construction sites—where a pre-assembled house simply couldn't reach.

- Zero-Waste Construction: Everything is pre-cut and pre-drilled in the factory. When the materials arrive at your site, there is no cutting, no welding, and zero construction waste, making it an eco-friendly "Green Building" solution.

- Labor Synergy: You don't need a specialized construction crew. With our detailed assembly drawings and video guides, general laborers can master the installation of a unit in just a few hours.

Key Performance Metrics

- Assembly Time: 3-4 persons / 3 hours per unit

- Logistics Efficiency: 14 units per 40ft HQ container

- Fire Resistance: Up to 120 minutes (with Rock Wool)

- Floor Loading:250kg - 300kg / m²

- Thermal Conductivity: Low (Optimized for energy saving)

Engineering Excellence: Materials Built for Durability

Precision Engineering & Premium Components for 20-Year Durability

- The Steel Skeleton: We utilize Q235B galvanized steel for the primary structure, with a frame thickness of 2.1mm to 3.0mm to ensure maximum load-bearing capacity.

- Surface Protection: Every steel component undergoes an electrostatic powder coating process (60-80μm) after galvanization to prevent rust in high-humidity or coastal environments.

- Insulation System:

- Rock Wool: Class A non-combustible material, ideal for high-safety requirement sites like oil and gas camps.

- EPS (Polystyrene): A cost-effective solution for moderate climates with excellent moisture resistance.

- PU (Polyurethane): Offers the highest thermal resistance (R-value) for extreme cold or heat.

- Integrated Drainage Design: Our roof system features an internal water gutter and downspout system hidden within the corner columns, ensuring the structure remains 100% leak-proof during heavy rain.

Tailored Solutions for Global Industries

Our detachable container units are not just simple boxes; they are versatile building blocks engineered to meet the rigorous demands of various global sectors. We provide specialized configurations that prioritize safety, speed, and durability.

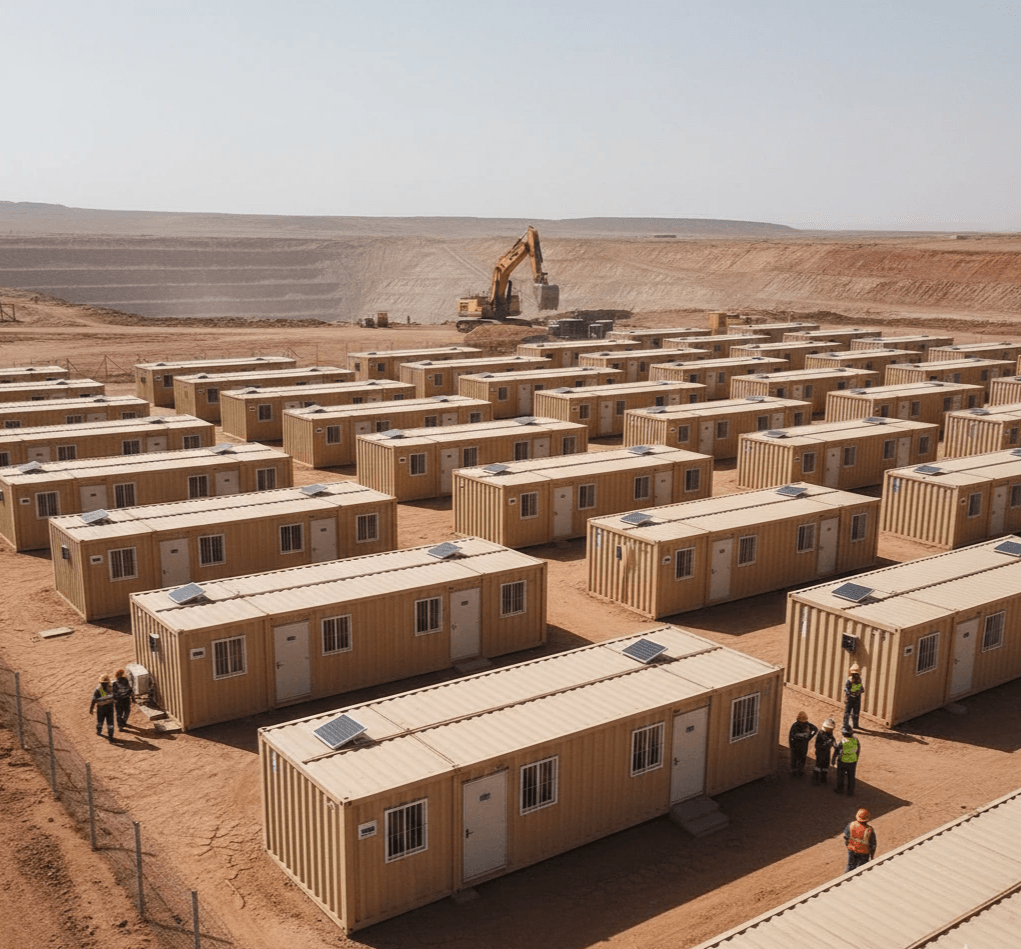

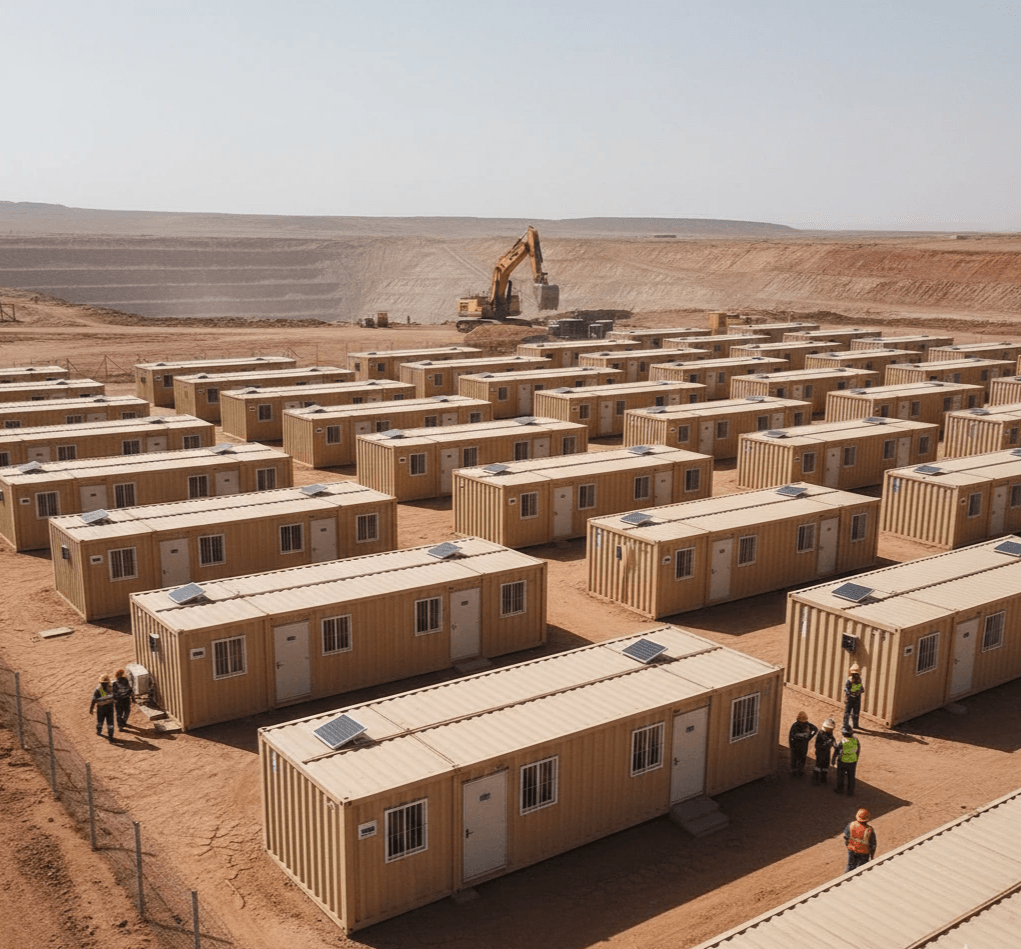

1. Remote Mining, Oil & Gas Camps

In remote extraction sites, the environment is often harsh, and logistics are a nightmare. We provide heavy-duty housing solutions designed for long-term endurance.

- Worker Accommodation: Multi-room layouts featuring high-density rock wool insulation for superior acoustic privacy and fire safety.

- Executive Suites: Upgraded units with internal partitions, integrated bathrooms, and premium PVC flooring.

- Communal Facilities: Specialized large-span designs for industrial kitchens, dining halls, and laundry units that can be bolted together to create massive communal spaces.

- Climate Resistance: Reinforced structures capable of withstanding extreme temperature fluctuations and high-velocity desert winds.

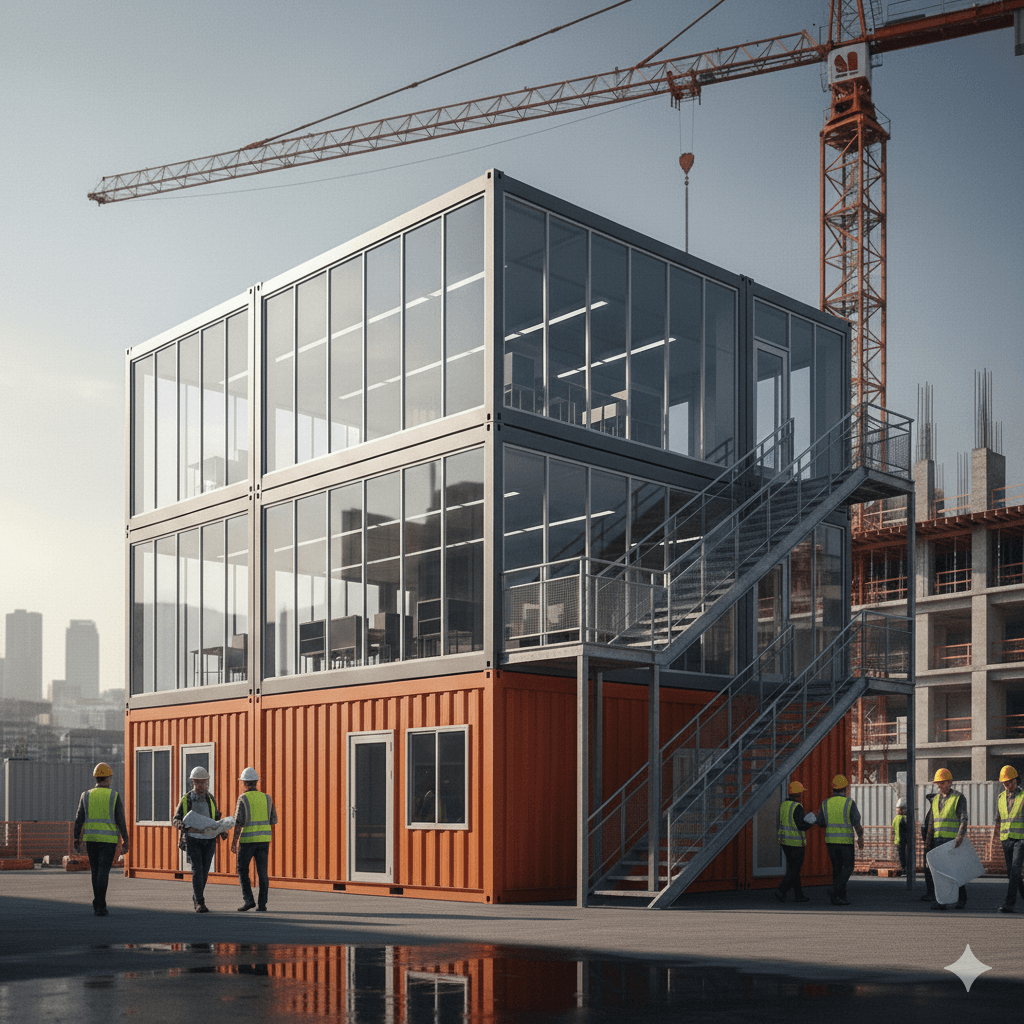

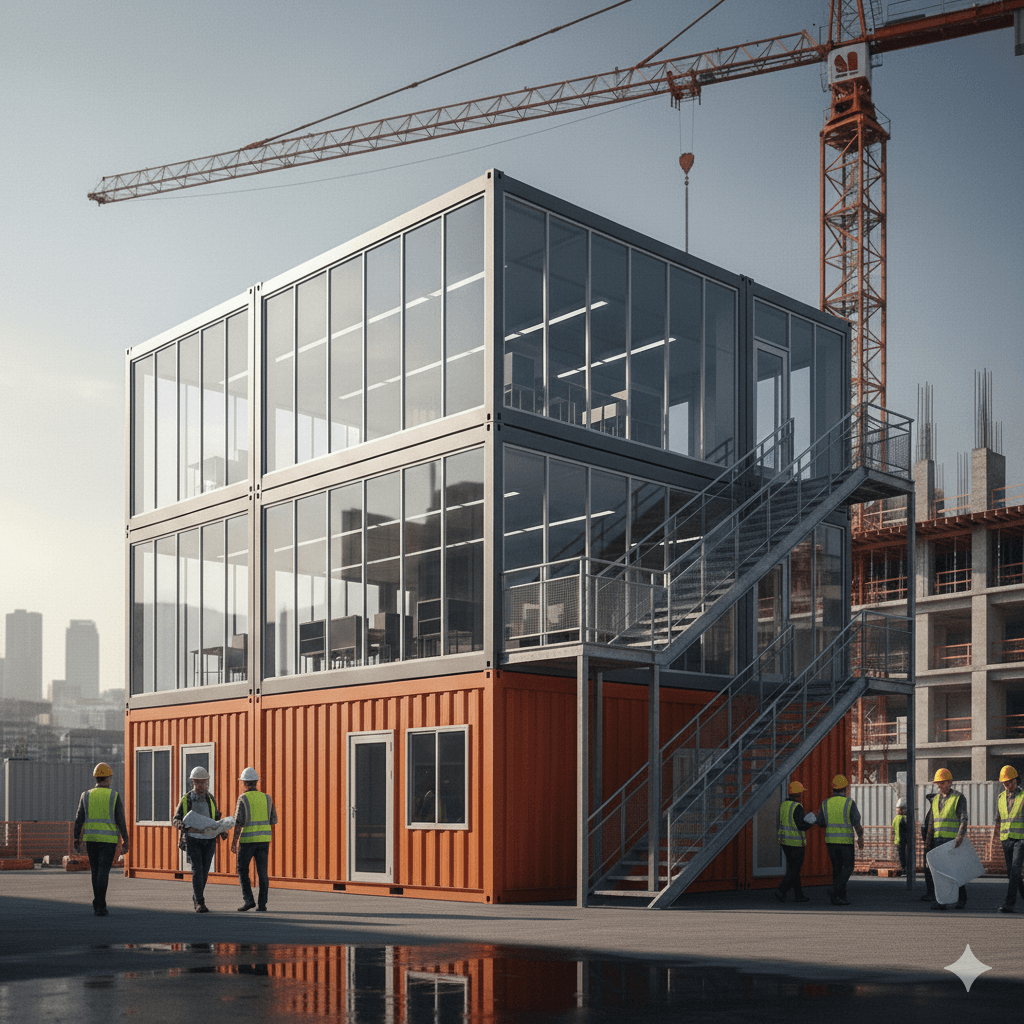

2. Construction Site Infrastructure

Efficiency is the key to a profitable construction project. Our detachable system allows for rapid deployment and maximum site utilization.

- Stackable Site Offices: Our high-tensile steel frames allow for stacking up to 3 stories, which is essential for urban projects with limited ground footprints.

- Meeting Rooms & Showrooms: Customized with large glass curtain walls to create a professional environment for client meetings and project presentations.

- Worker Dormitories: Cost-effective EPS or Rock Wool units that can be quickly disassembled and relocated to the next project site once the current phase is complete.

- Ablution Blocks: Specialized containers with waterproof cement board flooring and pre-installed plumbing for toilets and showers.

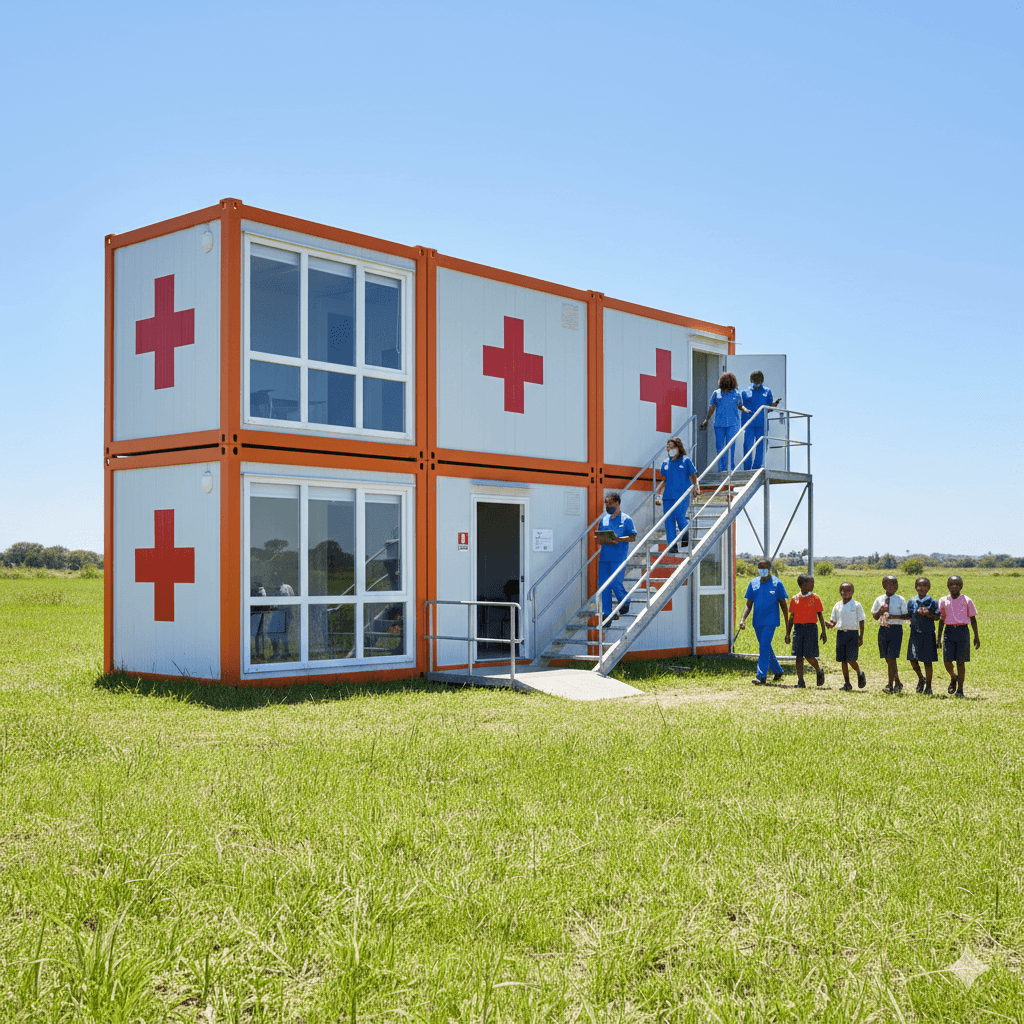

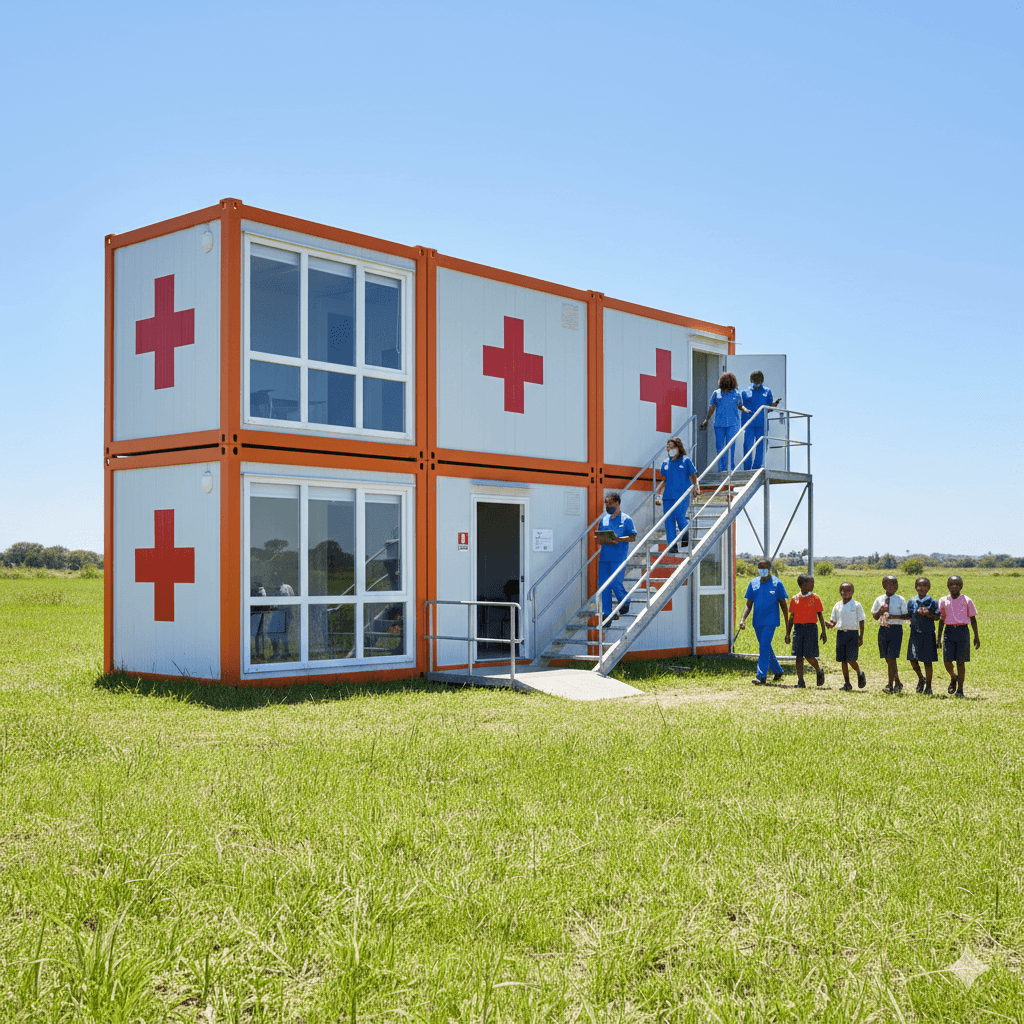

3. Temporary Medical & Healthcare Facilities

In emergency scenarios, speed saves lives. Our "bolt-together" modular system is the gold standard for rapid medical response.

- Isolation Wards: Easy-to-sanitize interior wall panels and independent ventilation systems help prevent cross-contamination.

- Mobile Clinics & Pharmacies: Compact, secure units that can be shipped to disaster zones or rural areas lacking permanent infrastructure.

- Staff Housing: Comfortable, private living quarters for medical personnel located directly on-site.

- Rapid Deployment: Hundreds of units can be transported in a single shipment (14 units per 40HQ) and assembled in hours using local labor.

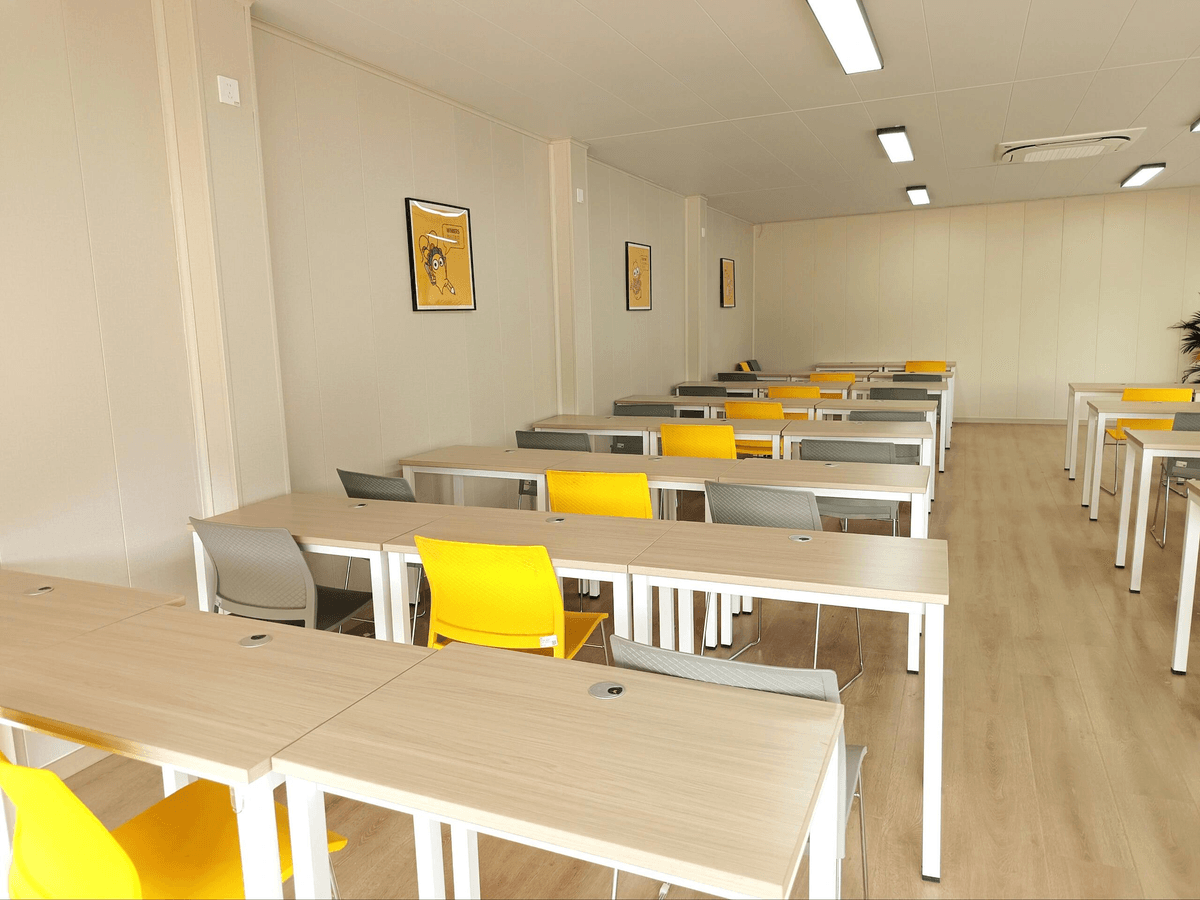

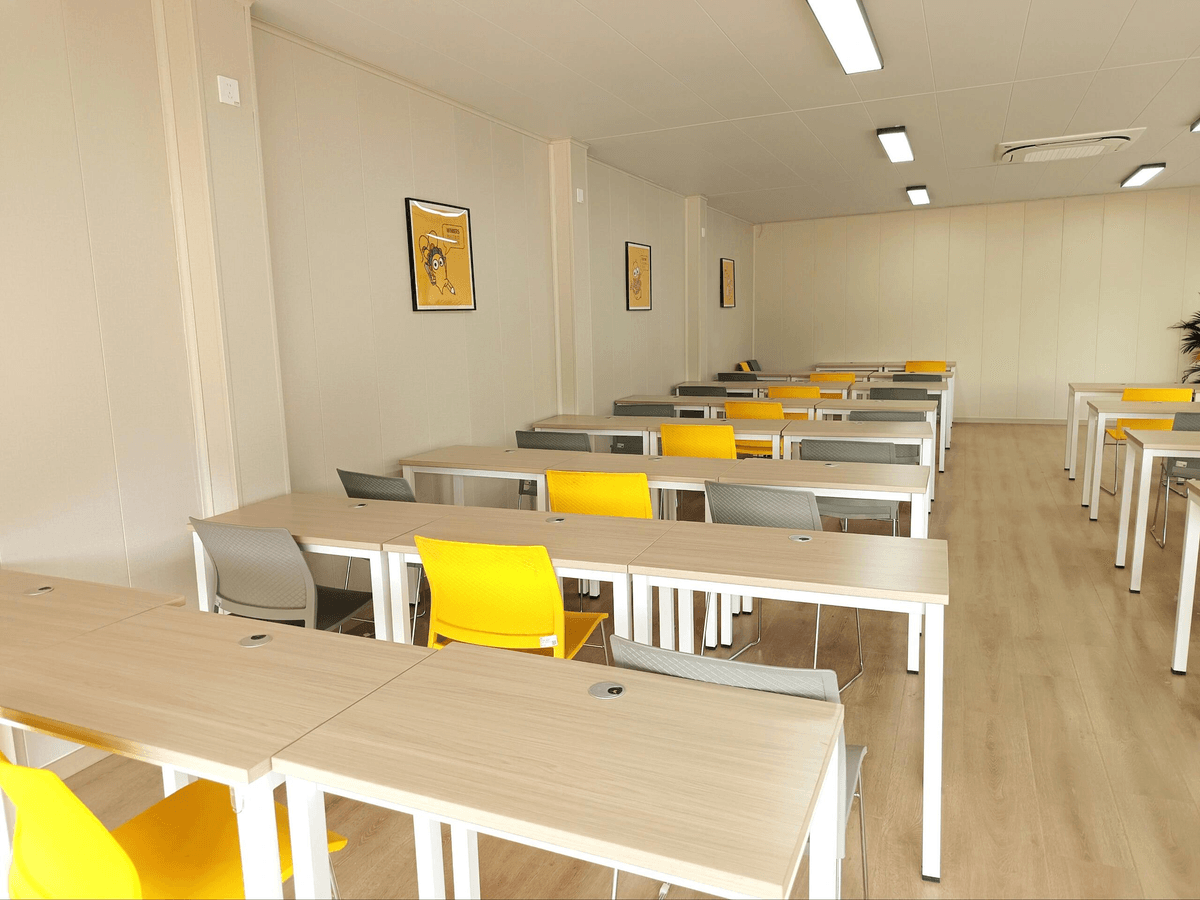

4. Education & Public Infrastructure

Governments and NGOs utilize our modular systems to bridge the gap in public services.

- Modular Classrooms: Designed with large windows to ensure adequate natural lighting and ventilation for students.

- Administrative Offices: Professional workspaces for school faculty, including pre-wired electrical and data ports.

- Security Guard Houses: Small, single-unit structures (3m x 6m) equipped with 360-degree visibility for site security.

- Portable Restrooms: Durable public toilet units with integrated water management systems for music festivals or public parks.

Frequently Asked Questions About

Detachable Container Houses

How many detachable units can fit into a 40ft HQ shipping container?

What is the expected lifespan and durability of the structure?

Is the roof system 100% waterproof during heavy tropical storms?

Do I need specialized equipment or welding to assemble the units on-site?

Can these modular units be stacked for multi-story buildings?

Are the materials fire-rated and safe for industrial camps?

Get Your Free Quote Now

Feel free to reach out to us through any of the contact options provided below.

We'll get in touch with you within 24 hours.

Select...

About Prefabhouse

A high-tech enterprise driven by innovation, global vision, and excellence in prefab housing solutions.

Subscribe to Get Latest Update!

Copyright © 2025 Prefabhouse Manufacturer