Introduction

In recent years, the construction industry has witnessed a transformative shift towards modular building structures, revolutionizing how we think about design and construction. These innovative approaches allow for efficient and effective solutions that cater to various needs in both residential and commercial sectors. As we delve into the world of modular construction, it’s essential to understand its benefits, key players, and the intricacies that define this modern method.

Understanding Modular Building Structures

Modular building structures are prefabricated units created in a controlled factory environment before being transported to the construction site for assembly. This method contrasts sharply with traditional on-site building techniques, where construction takes place entirely at the location over extended periods. By utilizing modular building structures, builders can streamline their processes and ensure higher quality control while reducing waste.

Benefits of Modular Construction

The benefits of modular construction are numerous, making it an appealing choice for many developers and architects alike. First and foremost, these structures offer significant cost savings due to reduced labor hours and minimized material waste during production. Additionally, modular building structures can be completed much quicker than conventional methods—often cutting project delivery times in half—allowing businesses to occupy their spaces sooner.

Key Players in Modular Building

In the realm of modular construction, several key players contribute to its success—from manufacturers like PreFab Inc., who specialize in creating high-quality modules, to architects who design functional layouts tailored for modular systems. Additionally, contractors play a crucial role in ensuring seamless transportation and installation of these prefabricated units on-site. Together, these professionals foster an ecosystem that promotes innovation and efficiency within the modular building landscape.

What is Modular Building?

Modular building is revolutionizing the construction landscape by offering innovative, efficient, and flexible solutions. This approach involves creating structures in pre-fabricated sections or modules that are then transported to the construction site for assembly. With a modular building structure, projects can be completed faster and often at a reduced cost compared to traditional methods.

Defining Modular Building Structures

A modular building structure consists of multiple sections manufactured off-site under controlled conditions before being assembled on-site. These structures can range from simple residential homes to complex commercial buildings, all designed with high precision and quality in mind. By utilizing a modular approach, builders can ensure that each component fits seamlessly together, resulting in a sturdy and reliable end product.

History of Modular Construction Techniques

The history of modular construction techniques dates back centuries but gained significant momentum during World War II when quick housing solutions were needed for returning soldiers. Over the decades, advancements in technology have transformed these techniques into what we see today—a dynamic industry capable of producing sustainable and customizable modular building structures. The evolution continues as modern materials and design philosophies push the boundaries of what’s possible in modular construction.

Future Trends in Modular Building

Looking ahead, the future trends in modular building are exciting and full of potential for innovation. With increasing emphasis on sustainability, many companies are integrating eco-friendly materials into their designs while also focusing on energy efficiency within their modular building structures. Furthermore, advancements in technology such as 3D printing and smart home integration promise to elevate the functionality and appeal of these structures even further—making them not just buildings but smart environments.

Types of Modular Building Methods

When it comes to modular building structures, there are several methods that stand out in the construction industry, each offering unique advantages and applications. Understanding these types can help project managers and builders make informed decisions that align with their specific needs and goals. Let’s dive into the various methods of modular construction, starting with a comparison between prefabricated and site-built structures.

Prefabricated vs. Site-Built Structures

Prefabricated structures are essentially built in sections or modules off-site before being transported to the final location for assembly. This method allows for greater control over quality and efficiency, as components can be manufactured in a controlled environment free from weather-related delays. In contrast, site-built structures are constructed entirely on-site, which can lead to longer timelines and increased exposure to environmental factors.

The key difference lies in how much of the modular building structure is completed before arriving at the site. Prefabricated buildings often use advanced technology and production techniques that streamline construction processes, making them more cost-effective overall. By choosing PreFab Inc., clients benefit from our expertise in prefabrication, ensuring high-quality results delivered on time.

Volumetric Modular Building Explained

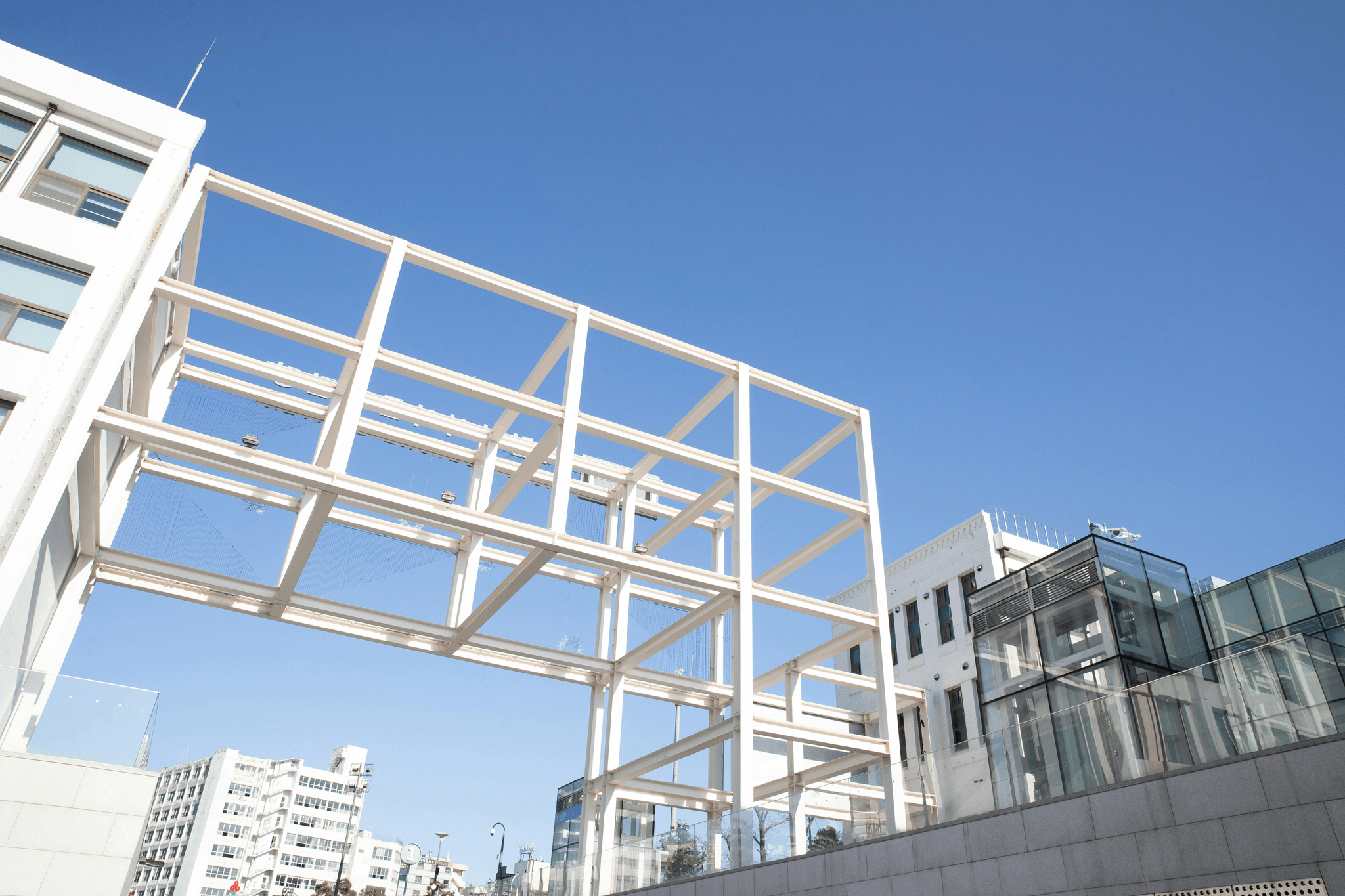

Volumetric modular building is a cutting-edge approach where entire rooms or sections of a building are constructed as three-dimensional units off-site before being transported for installation. This technique not only saves time but also enhances quality control since each module is built under strict supervision in a factory setting. Once on-site, these volumetric modules can be quickly assembled into a cohesive structure.

One of the standout features of volumetric modular building is its versatility; it can be used for residential homes, hotels, schools, and even healthcare facilities! The ability to stack or connect these units allows architects to design innovative layouts while maximizing space efficiency within urban settings. PreFab Inc.’s volumetric solutions are perfect for those looking to revolutionize their projects with speed without sacrificing quality.

Panelized Systems and Their Advantages

Panelized systems involve constructing wall panels or other structural components separately before assembling them on-site into a complete framework for the modular building structure. This method offers flexibility in design while significantly reducing construction time compared to traditional methods. The panels are typically made from materials such as wood or steel and come pre-insulated for improved energy efficiency.

One major advantage of panelized systems is their adaptability; they can easily accommodate various architectural styles while allowing builders to customize features according to client preferences. Additionally, because these panels are manufactured off-site, there’s less waste generated during construction—a win-win for both budget-conscious clients and environmentally aware builders alike! With PreFab Inc.’s panelized options, your project will benefit from rapid assembly times without compromising structural integrity.

The Process of Modular Construction

Modular construction is a fascinating journey that transforms innovative designs into tangible structures, all while maintaining efficiency and quality. The process involves several critical phases, each contributing to the seamless creation of a modular building structure. From initial design to final installation, every step is carefully orchestrated to ensure the end result meets the highest standards.

Design and Planning Phase

The design and planning phase is where creativity meets practicality in the world of modular building structures. Architects and engineers collaborate closely to create blueprints that not only reflect aesthetic desires but also adhere to local regulations and site conditions. This phase sets the stage for success, as careful planning can mitigate future challenges related to logistics or site limitations.

At PreFab Inc., we utilize advanced software tools that allow us to visualize modular building structures in 3D before any physical work begins. This technology enables clients to see their project come alive digitally, making adjustments easier and more efficient. By investing time in this phase, we ensure that our modular buildings are not just functional but also tailored perfectly to our clients’ needs.

Manufacturing and Assembly

Once the designs are finalized, it’s time for manufacturing—a crucial step that brings modular building structures to life in a controlled environment. Factories specialized in modular construction produce individual modules based on precise specifications outlined during the design phase. This process often involves assembling walls, floors, roofs, and other components under optimal conditions, ensuring high-quality craftsmanship.

PreFab Inc.’s manufacturing facilities are equipped with state-of-the-art technology that enhances precision while minimizing waste—a win-win for both budget-conscious clients and environmentally mindful projects alike. Each module undergoes rigorous quality checks before leaving the factory floor, ensuring every piece fits seamlessly together during assembly on-site. The efficiency gained through this method significantly reduces construction timelines compared to traditional methods.

Transportation and Installation

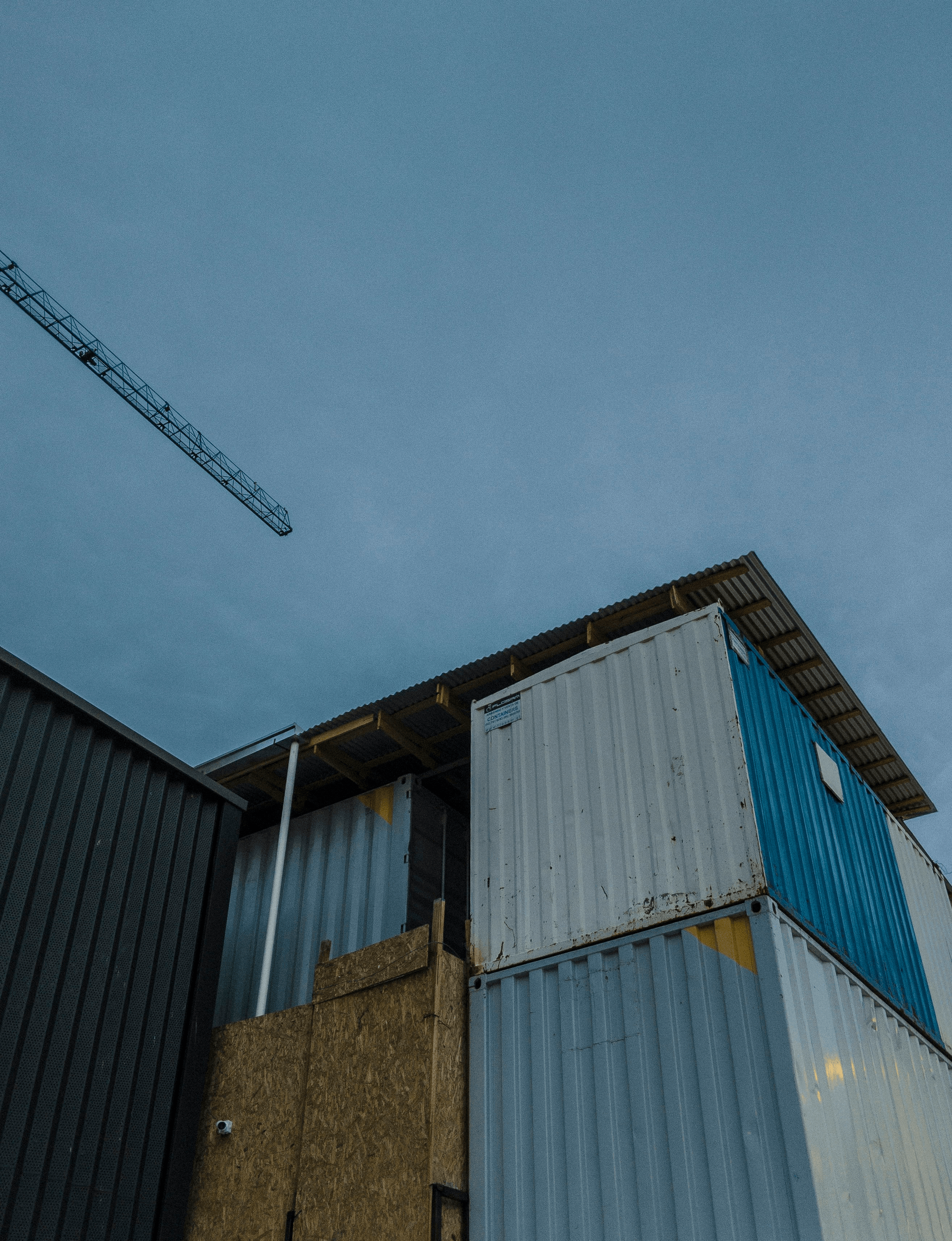

Now comes one of the most exciting parts: transportation and installation! After manufacturing is complete, each module is carefully transported from our facility to its designated site—often requiring meticulous planning due to logistics hurdles like road access or local regulations related to oversized loads. Our team at PreFab Inc. coordinates these movements expertly so that nothing stands between your vision and reality.

Upon arrival at the site, skilled crews begin assembling these pre-manufactured modules into a cohesive structure—this is where your modular building structure truly takes shape! Cranes lift each piece into place with precision while workers secure them together according to stringent safety standards. In no time at all, what started as a concept transforms into a fully functional space ready for occupancy.

Benefits of Modular Building Structures

Modular building structures have revolutionized the way we approach construction, offering a range of benefits that traditional methods often struggle to match. From cost savings to environmental sustainability, these innovative constructions are not just a trend; they're shaping the future of architecture. Let's dive into some key advantages that make modular building an attractive choice for developers and homeowners alike.

Cost-Effectiveness in Construction

One of the standout benefits of modular building structures is their cost-effectiveness in construction. By utilizing prefabricated components manufactured in a controlled environment, PreFab Inc. can significantly reduce labor costs and material waste, translating to savings for clients. Additionally, the streamlined assembly process minimizes on-site labor expenses and reduces overall project timelines—making it easier to stick to budgets.

Moreover, bulk purchasing of materials for modular building structures allows manufacturers like PreFab Inc. to secure lower prices from suppliers, further driving down costs. This financial efficiency is particularly beneficial for large-scale projects where every penny counts. In essence, when you choose modular construction, you’re not just investing in a structure; you're making a smart financial decision.

Time Efficiency in Project Delivery

Time is money in the world of construction, and modular building structures shine when it comes to project delivery timelines. With much of the work completed off-site at PreFab Inc.'s facilities, projects can progress simultaneously on multiple fronts—designing, manufacturing, and site preparation all happen concurrently rather than sequentially. This parallel process can cut project durations by up to half compared to traditional methods.

Once components arrive on-site, assembly is swift and efficient due to precise manufacturing standards and pre-engineered designs. This rapid installation not only accelerates project completion but also allows clients to start using their new spaces sooner than expected—an invaluable advantage in today’s fast-paced market. Ultimately, time efficiency leads to earlier returns on investment for those who opt for modular building solutions.

Sustainability and Eco-Friendliness

In an era where environmental consciousness is paramount, modular building structures offer an eco-friendly alternative that aligns with sustainable practices. PreFab Inc.’s commitment to minimizing waste during production results in less material being discarded compared to traditional construction methods—contributing positively toward reducing landfill burdens. Furthermore, many modular buildings are designed with energy-efficient systems that minimize long-term energy consumption.

Additionally, because components are manufactured off-site under controlled conditions, there’s less disruption at construction sites which helps preserve local ecosystems and reduces carbon footprints associated with transportation logistics during assembly phases. By choosing modular buildings from companies like PreFab Inc., clients not only achieve their architectural goals but also contribute positively toward global sustainability efforts—a win-win situation!

Challenges in Modular Building Techniques

While modular building structures offer numerous advantages, they are not without their challenges. Understanding these hurdles is crucial for stakeholders in the construction industry, as overcoming them can lead to successful project completions. Let's delve into some of the primary challenges faced by modular construction.

Site Limitations and Regulations

One of the most significant challenges in modular building structures is navigating site limitations and regulatory requirements. Each location has its own zoning laws, building codes, and environmental regulations that must be adhered to before any modular structure can be erected. These regulations can complicate the planning phase, sometimes leading to delays or increased costs if modifications are required to meet compliance standards.

Moreover, site limitations such as space constraints or geographical features can impact how a modular building structure is designed and installed. For instance, a narrow urban lot may restrict access for transporting large modules, necessitating creative logistical solutions. It's essential for companies like PreFab Inc. to work closely with local authorities and stakeholders to ensure all regulations are met while maximizing the potential of each site.

Logistics and Transportation Hurdles

Logistics play a pivotal role in the success of any modular building project; however, they also present unique challenges that require careful planning. Transporting large sections of a modular building structure from manufacturing facilities to job sites involves intricate coordination between various parties including suppliers, transporters, and installation teams. Delays in transportation can lead to costly downtime on-site and disrupt overall project timelines.

Additionally, transportation routes must be evaluated for feasibility before moving these massive modules; low bridges or narrow roads could pose serious risks during transit. Companies like PreFab Inc., known for their expertise in managing logistics effectively, often employ detailed planning strategies that account for potential obstacles along the way to ensure seamless delivery and installation processes.

Quality Control in Modular Construction

Quality control is another critical aspect that cannot be overlooked when discussing modular building structures. Given that many components are manufactured off-site under controlled conditions, maintaining consistent quality throughout production is vital for ensuring structural integrity upon assembly at the final location. Any lapses in quality control could result in defects that compromise safety or lead to expensive repairs down the line.

Furthermore, once modules arrive on-site, there’s an added layer of complexity as different teams come together for assembly; miscommunication or lack of coordination can affect overall quality outcomes as well. To mitigate these risks, PreFab Inc. emphasizes rigorous quality assurance protocols at every stage—from design through manufacturing—to deliver top-notch modular building structures that stand the test of time.

Conclusion

As we wrap up our exploration of modular building structures, it’s clear that these innovative designs are not just a passing trend but a fundamental shift in the way we approach construction. The impact of modular building on architecture is profound, offering solutions that are both practical and forward-thinking. With companies like PreFab Inc. leading the charge, the future of construction looks brighter than ever.

The Impact of Modular Building on Architecture

Modular building structures have revolutionized architectural design by allowing for flexibility and creativity that traditional methods often restrict. Architects can experiment with unique configurations and materials without being bogged down by the lengthy timelines associated with conventional construction projects. This newfound freedom has sparked a wave of creativity in the industry, enabling designers to create stunning spaces that meet modern needs while maintaining aesthetic appeal.

Why Choose PreFab Inc. for Your Project

When it comes to choosing a partner for your modular building structure project, PreFab Inc. stands out as a leader in quality and innovation. Our commitment to excellence ensures that every module is crafted with precision, meeting rigorous standards while still being cost-effective and timely. With our experienced team guiding you through each phase—from design to installation—you can rest assured your project will be seamless and successful.

Embracing the Future of Modular Construction

The future of modular construction is bright, promising advancements in technology and sustainability that will only enhance its appeal. As more businesses recognize the benefits of modular building structures—such as reduced waste and faster completion times—the industry will continue to grow exponentially. By embracing this evolution now, you position yourself at the forefront of an architectural revolution that prioritizes efficiency without sacrificing style.