Introduction

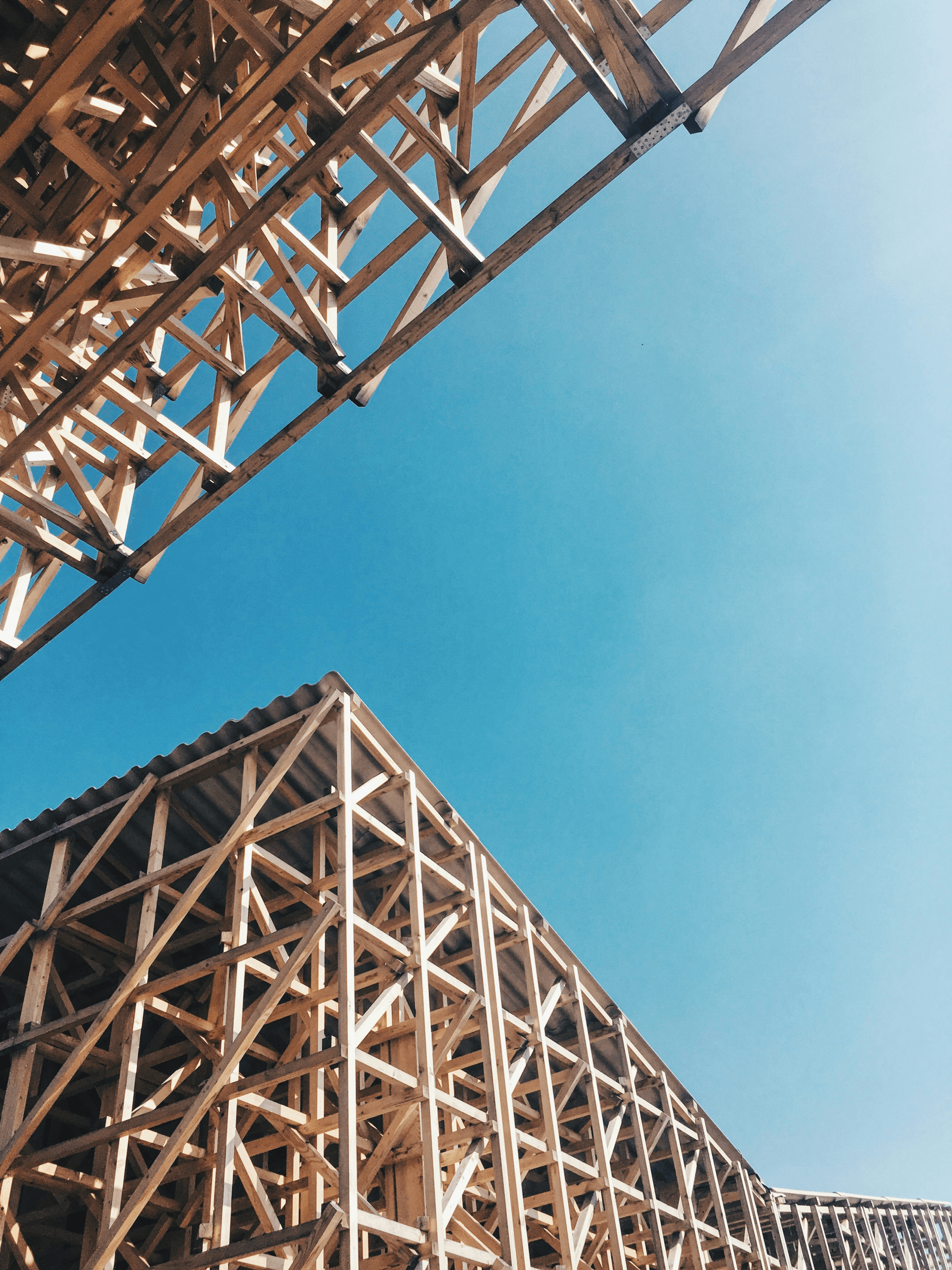

In recent years, the construction industry has witnessed a remarkable transformation with the rise of pre fab structures, which are revolutionizing how we think about building design and efficiency. These innovative solutions not only streamline the construction process but also address pressing issues like sustainability and housing shortages. As we delve into the world of pre fab structures, it becomes clear that this approach is not just a trend; it's a pivotal shift in how we construct our environments.

Understanding Pre Fab Structures Today

Pre fab structures represent a method of construction where components are manufactured off-site and then assembled on location. This approach reduces waste and project timelines while ensuring high-quality standards are met before the pieces ever reach their final destination. With companies like PreFab Inc., leading the charge, pre fab structures have become synonymous with modern efficiency and cutting-edge design.

The Shift Towards Sustainable Design

Sustainability is no longer an afterthought in construction; it’s at the forefront of design philosophy today. The shift towards sustainable design within pre fab structures is driven by innovative materials and energy-efficient practices that minimize environmental impact while maximizing utility. As awareness grows, more builders are turning to pre fab solutions to create eco-friendly spaces that resonate with today’s conscientious consumers.

Key Players in Pre Fab Innovation

The landscape of pre fab innovation is populated by visionary companies and architects who are pushing boundaries to redefine what these structures can achieve. From tech-savvy startups to established firms like PreFab Inc., these key players are integrating advanced technologies and sustainable practices into their designs, setting new standards for quality and efficiency in construction. Their collaborative efforts ensure that pre fab structures not only meet current demands but also anticipate future needs, paving the way for smarter urban living.

Innovative Materials in Pre Fab Structures

In the world of pre fab structures, innovative materials are revolutionizing the construction landscape. These advancements not only enhance the efficiency and sustainability of building processes but also contribute to a more eco-friendly approach to urban development. With companies like PreFab Inc. leading the charge, the industry is witnessing an exciting transformation.

Sustainable Options for Construction

When it comes to sustainable options for construction, pre fab structures are at the forefront of innovation. Builders are increasingly opting for recycled materials and sustainably sourced timber to minimize environmental impact. By utilizing these eco-friendly resources, PreFab Inc. demonstrates how modern construction can align with green principles while still delivering robust and aesthetically pleasing buildings.

Additionally, innovations like bamboo and rammed earth are gaining traction as viable alternatives in pre fab design. These materials not only reduce carbon footprints but also offer unique visual appeal that can enhance urban landscapes. As we embrace these sustainable options, it's clear that pre fab structures can harmonize with nature rather than disrupt it.

The Rise of 3D Printing Technology

The rise of 3D printing technology is another game-changer for pre fab structures, allowing for unprecedented customization and efficiency in construction processes. This innovative approach enables builders to create intricate designs that were previously unimaginable while reducing waste significantly during production. PreFab Inc.'s commitment to harnessing this technology showcases how adaptability is essential in modern architecture.

Moreover, 3D printing allows for rapid prototyping and on-demand production, which streamlines supply chains and minimizes delays on projects. As this technology continues to evolve, we can expect pre fab structures to become even more accessible and affordable for a wider audience. Ultimately, 3D printing is not just a trend; it's a pivotal shift towards smarter building practices.

Advanced Insulation Solutions

Advanced insulation solutions play a critical role in enhancing the energy efficiency of pre fab structures. With innovations such as spray foam insulation and structural insulated panels (SIPs), buildings can maintain optimal temperatures while significantly reducing energy consumption over time. Companies like PreFab Inc., by integrating these advanced solutions into their designs, ensure that their pre fab structures are not only comfortable but also cost-effective.

Furthermore, improved insulation contributes to soundproofing capabilities within urban environments where noise pollution is often a concern. This aspect becomes increasingly relevant as cities grow denser and living spaces become smaller; effective insulation transforms compact living into cozy sanctuaries amidst bustling surroundings. As we look toward future developments in pre fab architecture, prioritizing advanced insulation will be key in creating sustainable urban habitats.

Prefabrication and Modular Housing

Prefabrication is revolutionizing urban living, offering innovative solutions to age-old challenges in housing design and construction. With the rise of pre fab structures, cities are beginning to embrace new forms of modular housing that are not only efficient but also environmentally friendly. These structures can be assembled quickly, allowing for a rapid response to the growing demand for urban dwellings.

Transforming Urban Living Spaces

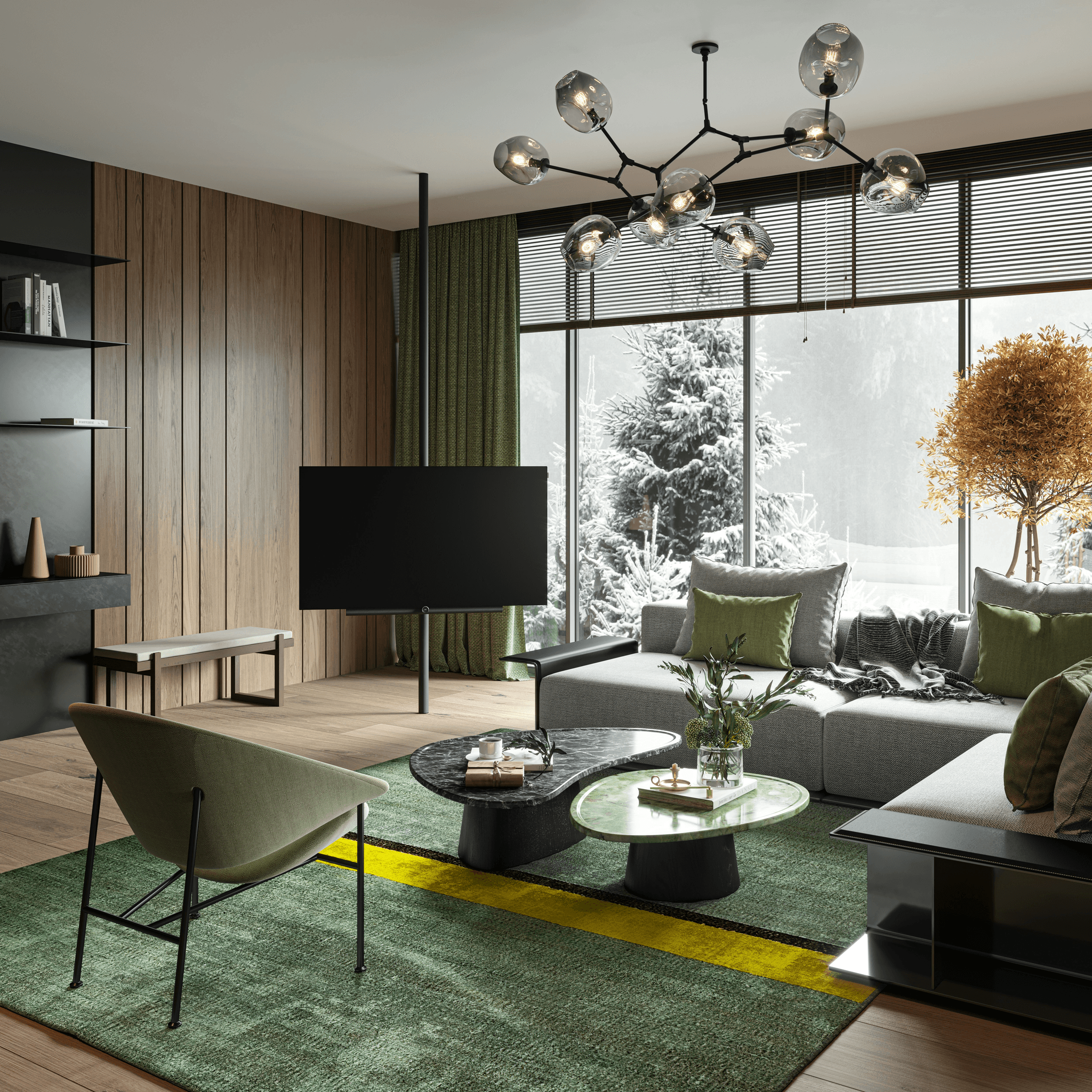

The transformation of urban living spaces through pre fab structures is nothing short of remarkable. These modular designs allow for flexibility in layout and function, catering to diverse lifestyles and family sizes. Imagine sleek, modern units popping up in previously underutilized areas—this is the future PreFab Inc. envisions with its cutting-edge approaches to modular housing.

Moreover, pre fab structures often prioritize sustainability without sacrificing style or comfort. By integrating eco-friendly materials and smart technologies, these homes can minimize their carbon footprint while providing residents with a chic living space. As cities evolve, this innovative approach ensures that urban environments remain vibrant and livable.

How Pre Fab Structures Combat Housing Shortages

Housing shortages are a pressing issue in many metropolitan areas, but pre fab structures offer a viable solution that addresses this crisis head-on. By streamlining construction processes and reducing build times significantly, modular housing can provide quick relief to communities struggling with inadequate housing supply. PreFab Inc.'s commitment to prefabrication means that more families can find affordable homes faster than ever before.

Additionally, these pre fab structures can be designed to fit various budgets without compromising quality or aesthetic appeal. This adaptability allows developers to create diverse housing options tailored specifically for different income levels within a community—essentially democratizing access to quality living spaces. Ultimately, by embracing prefabricated solutions, cities can effectively combat the ongoing challenge of housing shortages.

Examples of Successful Modular Communities

Across the globe, several successful modular communities showcase the potential of pre fab structures in transforming urban landscapes. One notable example is the “Boxhouse” project in Amsterdam—a stunning collection of sustainable units designed with both aesthetics and functionality in mind. Residents enjoy modern amenities while benefiting from energy-efficient features that reduce overall living costs.

Another inspiring case study comes from Canada’s “Mighty House,” where prefabricated modules were assembled on-site within mere weeks—providing much-needed shelter for families experiencing homelessness during harsh winters. This project highlights how swiftly implemented pre fab structures can make a significant impact on local communities facing urgent needs.

PreFab Inc.'s involvement in such projects demonstrates its dedication not only to innovation but also social responsibility—proving that modular housing is not just about building homes; it's about building futures for those who need them most.

The Role of Technology in Pre Fab Design

Technology has become the backbone of innovation in pre fab structures, revolutionizing the way we approach design and construction. From smart homes that adapt to our lifestyles to digital tools that streamline processes, technology is enhancing every aspect of pre fabrication. With companies like PreFab Inc. leading the charge, the future looks bright for efficient and sustainable living.

Smart Homes and Automation Integration

Smart home technology is no longer a futuristic concept; it’s becoming standard in new pre fab structures. These homes are equipped with automation systems that control lighting, heating, and security, allowing residents to manage their environments with ease. By integrating smart technology into pre fab designs, PreFab Inc. not only enhances comfort but also promotes energy efficiency—making it a win-win for homeowners and the planet.

The beauty of automation lies in its ability to learn from user behavior over time, creating a customized living experience that adapts to individual needs. Imagine waking up in your pre fab structure where the blinds automatically open at sunrise while your coffee brews on command! This level of convenience is changing how we think about homeownership and modern living.

Virtual Reality in Design and Planning

Virtual reality (VR) has emerged as a game-changer in the planning stages of pre fab structures, allowing architects and clients to visualize spaces before they are built. By immersing themselves in a 3D environment, stakeholders can explore layouts, make adjustments on-the-fly, and truly understand how their future home will function within its surroundings. PreFab Inc. harnesses this technology to ensure client satisfaction while minimizing costly changes during construction.

Moreover, VR can enhance collaboration among teams by providing an interactive platform for brainstorming sessions or design reviews—no more endless back-and-forth emails! This innovative approach not only saves time but also fosters creativity as everyone can contribute ideas from within the virtual space. Ultimately, VR helps bridge gaps between imagination and reality for pre fab structures.

Enhancing Efficiency Through Digital Tools

Digital tools are transforming project management within the realm of pre fabrication by streamlining workflows and improving communication among teams. Platforms that facilitate real-time updates allow everyone involved—from architects to contractors—to stay aligned throughout each phase of construction on a pre fab structure project. This increased efficiency means faster delivery times without sacrificing quality.

Additionally, advanced software solutions enable precise cost estimation and resource allocation—critical factors when building sustainable homes with limited budgets or tight timelines. Companies like PreFab Inc., utilizing these tools effectively, can maximize productivity while minimizing waste during construction processes associated with their innovative designs. The result? A smoother journey from concept to completion for every new pre fab structure.

Global Trends in Pre Fab Architecture

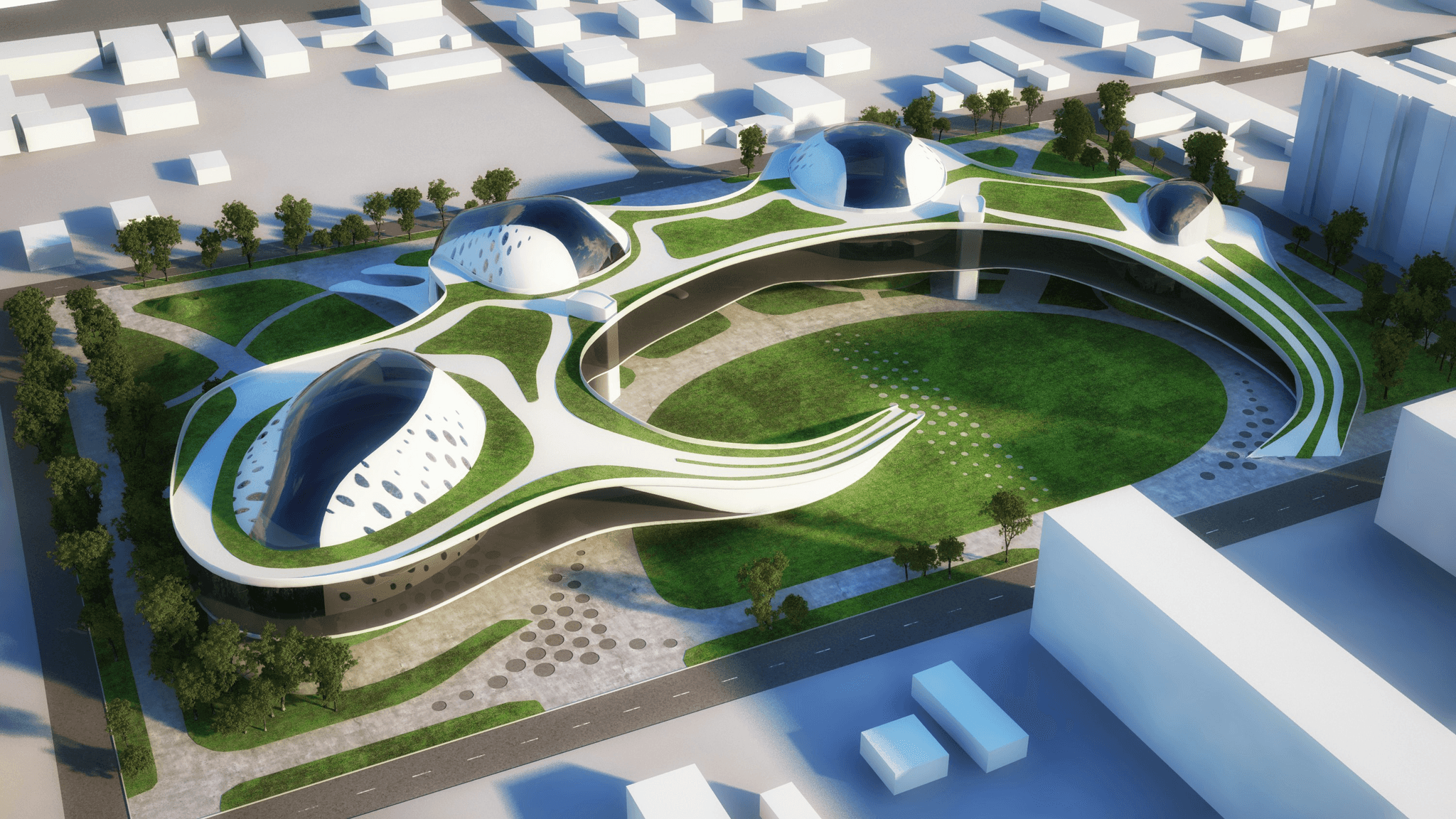

The world of pre fab architecture is not just about efficiency and speed; it’s a vibrant tapestry woven from diverse cultural influences, innovative design philosophies, and the urgent need for adaptable housing solutions. As communities around the globe face unique challenges—from urbanization to climate change—pre fab structures emerge as a versatile response that reflects local cultures while embracing modern technology. With companies like PreFab Inc. leading the charge, these structures are reshaping our understanding of what sustainable living can look like.

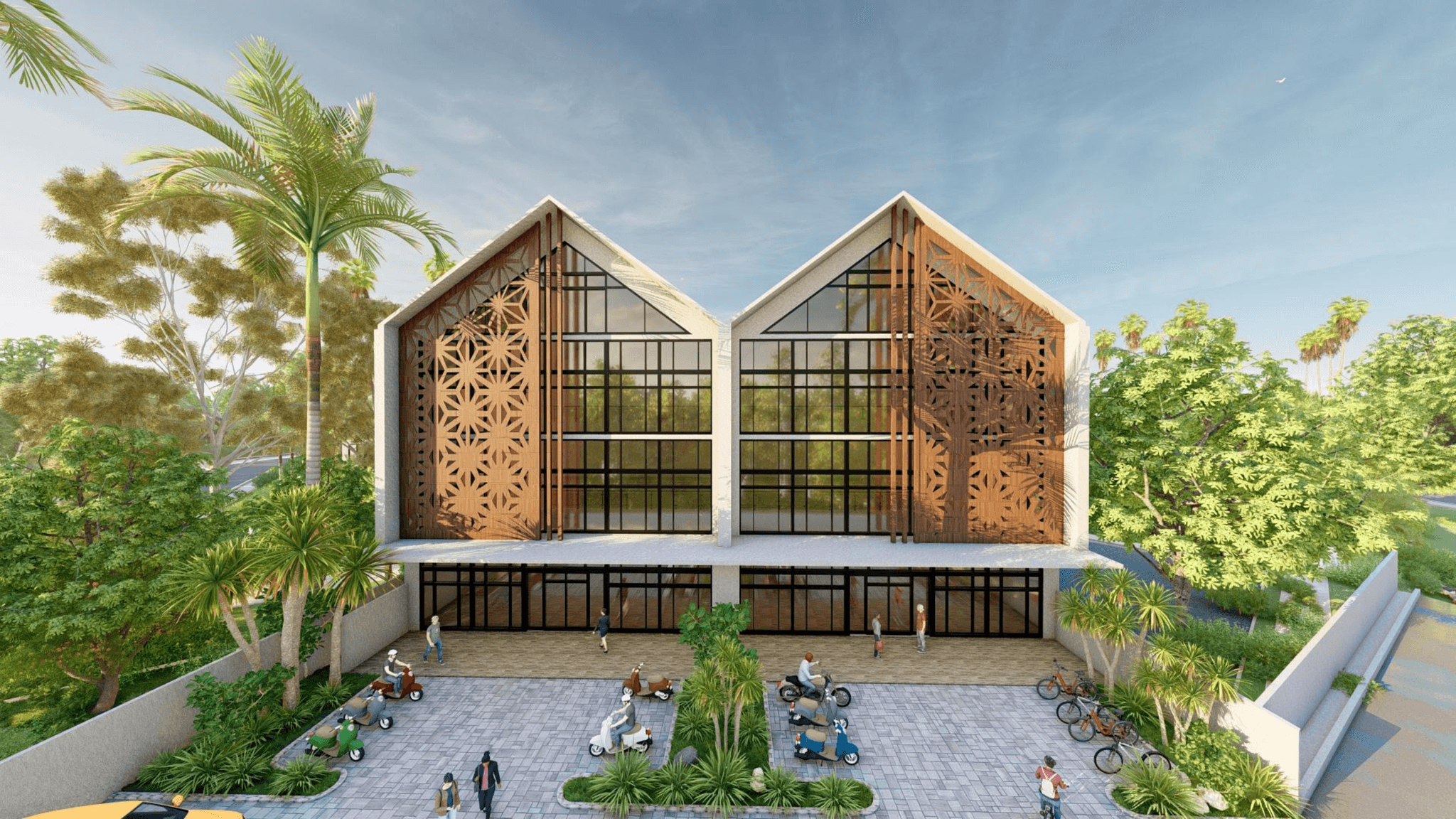

Cultural Influences on Design Choices

Cultural influences play a pivotal role in shaping pre fab structures, allowing them to resonate with local identities while addressing practical needs. In Japan, for example, minimalist aesthetics combined with modular designs reflect both tradition and modernity, creating homes that are not only functional but also culturally significant. Similarly, Scandinavian countries embrace sustainability in their pre fab architecture by incorporating natural materials and energy-efficient technologies that mirror their commitment to environmental stewardship.

Furthermore, regions with rich histories often see pre fab designs that pay homage to traditional styles while introducing contemporary elements. The fusion of old and new creates a unique architectural language that speaks to both heritage and innovation. By understanding these cultural nuances, PreFab Inc. ensures that their offerings are not just buildings but integral parts of the communities they serve.

Case Studies from Leading Architects

Leading architects around the globe have embraced pre fab structures as a canvas for creativity and experimentation. One notable case is the work of Shigeru Ban in disaster-prone areas where he has utilized innovative materials to create temporary yet durable shelters that blend seamlessly into their surroundings. His approach showcases how pre fab can be both functional and aesthetically pleasing, proving that necessity can indeed birth beauty.

Another striking example comes from BIG (Bjarke Ingels Group), which has developed modular housing solutions in urban environments designed to maximize space while minimizing ecological footprints. Their projects highlight how pre fab structures can adapt to dense cityscapes without compromising on quality or style—an essential consideration as urban populations continue to swell. These case studies underscore how visionary architects are pushing boundaries within the realm of prefabrication.

Pre Fab Structures in Disaster Relief Efforts

Pre fab structures have gained significant traction in disaster relief efforts due to their rapid deployment capabilities and adaptability under pressing circumstances. In regions affected by natural disasters, such as earthquakes or hurricanes, these modular homes provide immediate shelter solutions while ensuring safety and comfort for displaced populations. Organizations often partner with companies like PreFab Inc., leveraging their expertise in creating resilient designs tailored specifically for crisis situations.

Moreover, the use of sustainable materials in these emergency constructions aligns perfectly with global calls for environmentally friendly practices even amid chaos—a testament to how thoughtful design can prevail even during challenging times. The ability of pre fab structures to be assembled quickly allows communities not only to recover faster but also rebuild smarter for future resilience against calamities.

Future of Pre Fab Structures in Urban Development

The future of pre fab structures in urban development is bright and brimming with potential. As cities grapple with rapid population growth and housing shortages, the integration of prefabricated solutions into city planning is not just a trend; it's a necessity. With innovative designs and sustainable materials, pre fab structures can revolutionize how urban spaces are utilized, making them more efficient and livable.

Integrating Pre Fab into City Planning

Integrating pre fab structures into city planning can streamline the construction process and reduce timeframes significantly. Cities can leverage modular designs to create affordable housing options quickly, addressing urgent needs without compromising quality. Moreover, by incorporating these structures into existing frameworks, urban planners can enhance green spaces and community areas while maintaining the architectural integrity of neighborhoods.

Incorporating pre fab solutions also means cities can adapt more flexibly to changing demographics and economic conditions. For example, modular units can be added or removed as needed without extensive renovations or disruptions to surrounding communities. This adaptability is crucial in today’s fast-paced world where urban environments must evolve rapidly.

The Economic Benefits of Prefabrication

The economic benefits of prefabrication extend beyond mere cost savings; they include job creation and boosting local economies as well. By utilizing local resources for constructing pre fab structures, communities can support their economies while minimizing transportation costs and carbon footprints associated with traditional building methods. Furthermore, faster construction timelines mean that investments yield returns more quickly than conventional projects.

PreFab Inc., for instance, exemplifies how embracing prefabricated techniques not only accelerates project completion but also enhances overall project viability through reduced labor costs. These savings allow for reinvestment in other vital community services or infrastructure improvements that further benefit residents. Ultimately, the economic advantages make a compelling case for integrating pre fab solutions into urban development strategies.

Predictions for Market Growth and Sustainability

Looking ahead, the market for pre fab structures is poised for significant growth driven by sustainability trends and technological advancements. As environmental concerns take center stage in global discussions about construction practices, the demand for eco-friendly building solutions will likely surge—making prefabrication an attractive option due to its inherent efficiency and waste reduction capabilities.

Experts predict that by 2030, we could see a marked increase in the adoption of pre fab technologies across various sectors including residential housing, commercial buildings, and even disaster relief efforts worldwide. With companies like PreFab Inc., leading this charge through innovation in design and materials usage, it’s clear that sustainable practices will shape not only the future of architecture but also our very cities themselves.

Conclusion

In the ever-evolving landscape of construction, pre fab structures have emerged as a beacon of innovation and sustainability. The journey from traditional building methods to modern prefabrication has not only transformed how we think about space but also how we approach environmental responsibility. As we look ahead, it’s clear that pre fab innovations will continue to redefine our built environment.

The Evolution of Prefab Innovations

The evolution of pre fab structures has been nothing short of revolutionary, transitioning from simple modular designs to complex, customizable units that can meet diverse needs. This transformation is fueled by advances in technology and materials that make prefabrication more efficient and appealing than ever before. Companies like PreFab Inc. are at the forefront of this movement, continually pushing the boundaries of what’s possible in modular construction.

Major Benefits of Pre Fab Structures

One cannot overlook the myriad benefits offered by pre fab structures, which include reduced construction time, cost efficiency, and a smaller carbon footprint compared to traditional building methods. Prefabricated buildings are designed for rapid assembly on-site, minimizing disruption and waste while maximizing quality control during production. Moreover, these structures often incorporate sustainable materials and practices that align with today’s eco-conscious mindset.

Why Pre Fab Inc. is Leading the Way

PreFab Inc.’s commitment to innovation sets it apart in the competitive world of prefabrication; they leverage cutting-edge technology to create versatile pre fab structures that cater to various markets—from residential homes to commercial spaces. Their focus on sustainability not only meets consumer demands but also addresses critical housing shortages in urban areas through smart design solutions. With a keen eye on future trends and market growth, PreFab Inc. is poised to lead the charge toward a more sustainable urban development landscape.