Introduction

In recent years, the construction industry has witnessed a remarkable transformation with the rise of volumetric modular construction. This innovative approach not only streamlines building processes but also enhances sustainability and efficiency, making it a game-changer in how we think about architecture and design. Companies like PreFab Inc. are at the forefront of this revolution, leading the charge towards a future where prefab structures become the norm rather than the exception.

The Rise of Volumetric Modular Construction

Volumetric modular construction is rapidly gaining traction as an effective solution to many challenges faced by traditional building methods. By assembling buildings in pre-fabricated sections or modules, this technique allows for quicker project completion and reduced on-site labor costs. As urbanization continues to increase, volumetric modular construction offers a scalable option that meets the growing demand for housing and commercial spaces.

Why Prefab is Taking Over

So why is prefab taking over? The answer lies in its numerous advantages: faster construction times, lower costs, and less waste compared to conventional methods. With companies like PreFab Inc. pioneering these advancements, it's clear that volumetric modular construction is not just a trend; it's becoming an essential part of modern architecture that appeals to builders and clients alike.

Trends Shaping the Future of Building

The future of building is being shaped by several key trends that are intertwined with volumetric modular construction. Sustainability is at the forefront, driving innovations in materials and practices that reduce environmental impact while enhancing energy efficiency. Additionally, technological advancements such as digital twins and automation are revolutionizing how we design and construct buildings, ensuring that companies like PreFab Inc. remain competitive in an ever-evolving landscape.

What is Volumetric Modular Construction?

Volumetric modular construction is transforming the way we think about building design and execution. This innovative approach involves constructing entire sections of a building—known as modules—off-site in a controlled environment before transporting them to the final location for assembly. With its emphasis on efficiency and quality, volumetric modular construction is rapidly becoming a preferred method in the construction industry.

Definition and Key Features

At its core, volumetric modular construction refers to the process of creating three-dimensional modules that can be prefabricated in a factory setting. These modules are typically fully equipped with essential services like plumbing, electrical wiring, and finishes before they arrive on-site, minimizing time spent on traditional construction methods. Key features include improved precision due to factory conditions, reduced waste through optimized material use, and enhanced safety standards thanks to controlled environments—all hallmarks of PreFab Inc.'s commitment to excellence.

Benefits Over Traditional Methods

The benefits of volumetric modular construction are numerous and compelling. First off, it significantly reduces construction timelines; projects that might take months or even years can often be completed in weeks with this method. Additionally, it lowers labor costs by minimizing on-site work while enhancing overall quality control—an area where PreFab Inc. excels by leveraging advanced manufacturing techniques.

Moreover, volumetric modular construction promotes sustainability by reducing material waste and energy consumption during both production and assembly phases. This eco-friendly approach aligns perfectly with current trends toward greener building practices, making it an attractive option for developers looking to meet stringent environmental regulations.

Real-World Applications

Volumetric modular construction has found its way into various sectors, including residential housing, commercial buildings, and healthcare facilities. For instance, several high-rise apartment complexes have successfully utilized this method to provide affordable housing solutions without compromising quality or aesthetics. Notably, PreFab Inc.'s collaborations have resulted in landmark projects that showcase the versatility of volumetric modular design across different environments.

In addition to residential applications, educational institutions are increasingly adopting volumetric modular approaches for quick expansions or renovations of existing structures. The adaptability of this method allows schools to respond promptly to growing student populations while maintaining budgetary constraints—a win-win scenario!

Innovative Materials in Modular Construction

The landscape of volumetric modular construction is evolving rapidly, driven by innovative materials that enhance sustainability and efficiency. As the industry embraces eco-friendly practices, sustainable building materials are becoming paramount in the design and execution of modular projects. This shift not only reduces environmental impact but also appeals to a growing demographic of eco-conscious consumers and businesses.

Sustainable Building Materials

Sustainable building materials play a pivotal role in volumetric modular construction, providing solutions that minimize waste and promote energy efficiency. From recycled steel to bamboo, these materials reduce the carbon footprint associated with traditional construction methods. Companies like PreFab Inc. are leading the charge by integrating these sustainable options into their designs, ensuring that modern buildings are both environmentally friendly and aesthetically pleasing.

Using innovative insulation materials made from natural fibers or bio-based composites further enhances energy efficiency in modular units. These advancements not only contribute to lower operational costs but also create healthier living environments for occupants. With sustainability at the forefront, volumetric modular construction is setting new standards for responsible building practices.

Advances in Prefabrication Technology

The realm of prefabrication technology has witnessed remarkable advancements that streamline the production process in volumetric modular construction. Automated systems and robotics are now commonplace on factory floors, allowing for precision manufacturing that was previously unattainable. This increased efficiency translates into faster project completion times, which is music to the ears of developers eager to meet market demands.

Moreover, innovations such as 3D printing are revolutionizing how components are created for modular buildings. By enabling rapid prototyping and customization, these technologies allow firms like PreFab Inc. to offer tailored solutions that cater to specific client needs while maintaining high-quality standards. The marriage of technology and prefabrication ensures that volumetric modular construction remains competitive against traditional methods.

Case Study: The Edge in Amsterdam

A prime example of innovative materials in action can be seen at The Edge in Amsterdam—a landmark project showcasing the potential of volumetric modular construction combined with cutting-edge technology. Designed with sustainability as a core principle, this office complex utilizes energy-efficient systems alongside recycled materials throughout its structure. The result? A stunning architectural feat that not only meets but exceeds modern environmental standards.

PreFab Inc.'s involvement with similar projects highlights how collaboration can lead to groundbreaking outcomes within this sector. By leveraging advanced prefabrication techniques and sustainable resources similar to those used at The Edge, companies can create spaces that prioritize both functionality and ecological responsibility. As more developers look towards such exemplary models, it becomes clear that the future of building lies firmly within innovative materials and practices.

The Role of Technology in Modular Design

In the rapidly evolving world of volumetric modular construction, technology plays a pivotal role in transforming how we design and build. From cutting-edge digital tools to advancements in automation, these technologies enhance efficiency and precision while reducing waste. Companies like PreFab Inc. are at the forefront, leveraging these innovations to create smarter, more sustainable buildings.

Digital Twins and BIM Integration

Digital twins and Building Information Modeling (BIM) are revolutionizing volumetric modular construction by providing real-time insights into the building process. A digital twin is a virtual replica of a physical structure that allows architects and builders to simulate various scenarios before actual construction begins. By integrating BIM with digital twins, PreFab Inc. can optimize designs, streamline project timelines, and ensure that every module fits seamlessly into the overall project vision.

This integration not only enhances collaboration among stakeholders but also minimizes costly errors during construction. With accurate data at their fingertips, teams can make informed decisions quickly, keeping projects on track and within budget. Ultimately, this technological synergy is paving the way for more efficient volumetric modular construction practices.

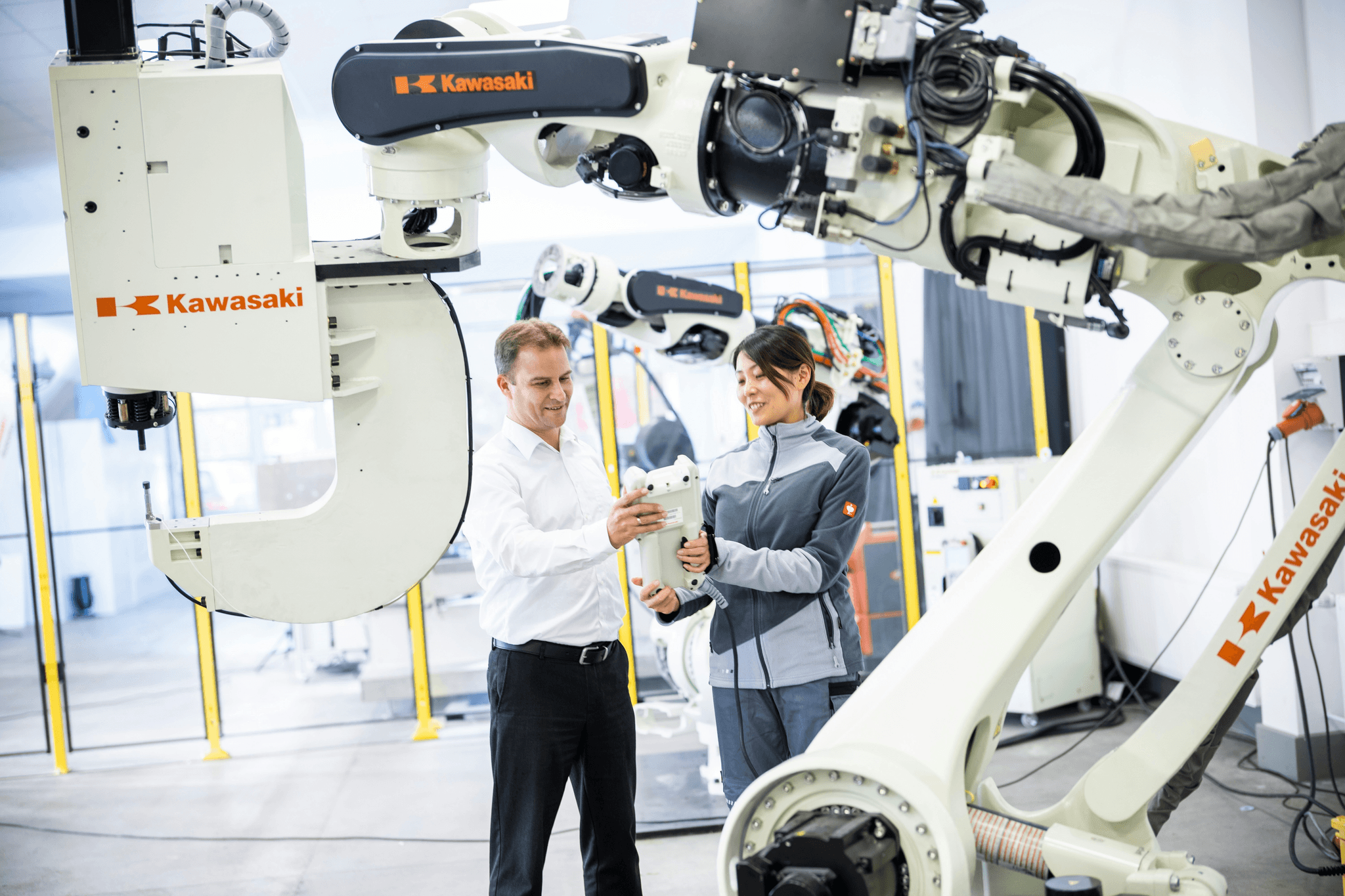

Automation in Manufacturing Processes

Automation is another game-changer in the realm of volumetric modular construction, enabling faster production times and improved quality control. Advanced robotics and automated machinery streamline the fabrication of building modules, ensuring precision that manual processes often cannot match. At PreFab Inc., automation not only boosts productivity but also allows skilled workers to focus on more complex tasks that require human ingenuity.

As factories become increasingly automated, they can produce modules with consistent quality while reducing labor costs significantly. This shift not only accelerates project timelines but also contributes to sustainability by minimizing material waste through efficient manufacturing processes. In essence, automation is redefining what’s possible in modular design.

Example: Factory of the Future

Imagine stepping into a factory where every aspect is optimized for efficiency—this is what we refer to as the Factory of the Future. In this innovative space dedicated to volumetric modular construction, advanced technologies converge seamlessly with traditional craftsmanship to produce high-quality modules at an unprecedented scale. At PreFab Inc., our vision for such a factory includes robotics working alongside skilled artisans who bring creativity into every module produced.

In this futuristic setting, real-time data analytics drive decision-making processes while automated systems handle repetitive tasks with precision—allowing human workers to innovate rather than just execute tasks mechanically. The result? A dynamic environment where speed meets quality without sacrificing sustainability or safety standards essential for modern building practices. This Factory of the Future exemplifies how technology will continue shaping volumetric modular construction as we move forward.

Global Leaders in Volumetric Modular Construction

Volumetric modular construction is transforming the building landscape, and several companies are leading the charge. These pioneers are not only innovating but also setting benchmarks for quality and efficiency in construction. With a commitment to sustainable practices and cutting-edge technology, they are shaping the future of how we build.

Companies at the Forefront

Among the key players in volumetric modular construction is Katerra, which has made significant strides by integrating technology into every phase of building. Another notable name is Modulus, known for its innovative designs that prioritize both aesthetics and functionality. PreFab Inc., too, stands out as a vital contributor in this space, focusing on creating customizable modular solutions that cater to diverse client needs.

These companies share a common goal: to streamline the construction process while reducing waste and improving speed. By leveraging advanced manufacturing techniques and sustainable materials, they are redefining traditional construction paradigms. Their collective efforts not only enhance project timelines but also ensure high-quality outcomes that resonate with modern architectural demands.

Notable Projects Around the World

Several remarkable projects highlight the impact of volumetric modular construction across various regions. One standout example is The Smile, a residential project in New York City that showcases how modular units can be both functional and visually appealing. In London, The Smile’s sister project demonstrates similar success by utilizing volumetric modules to address housing shortages quickly.

Internationally, projects like the CitizenM hotels have embraced this approach with great success; their prefabricated rooms allow for rapid hotel assembly without compromising design integrity or guest experience. Furthermore, Australia’s prefab housing initiatives exemplify how governments can leverage volumetric modular construction to provide affordable housing solutions swiftly and efficiently. Each of these projects illustrates how leaders in this field are pushing boundaries while delivering results.

Collaboration with PreFab Inc.

PreFab Inc.'s collaboration with industry giants significantly enhanced its footprint within volumetric modular construction. By partnering with established firms like Katerra and Modulus, PreFab Inc. gains access to shared resources and innovative technologies that elevate project outcomes further than ever before. This synergy allows them to adopt best practices from leaders in the field while contributing their unique expertise in customization.

Moreover, these partnerships enable PreFab Inc. to tackle larger-scale projects while maintaining quality control throughout every phase of development—something crucial in today’s competitive market landscape, where time is money! As they continue fostering collaborations within this vibrant ecosystem of innovators, PreFab Inc.’s role as a trailblazer will undoubtedly expand even further.

Regulatory Challenges and Solutions

In the realm of volumetric modular construction, navigating regulatory challenges can feel like trying to find your way through a maze with no exit signs. Building codes and zoning laws vary widely across regions, creating a complex landscape for developers and manufacturers alike. To successfully implement volumetric modular construction, it’s essential to understand these regulations and how they impact the design and delivery of modular buildings.

Navigating Building Codes

Building codes are the first hurdle in the journey of volumetric modular construction. These codes dictate everything from structural integrity to fire safety, ensuring that buildings meet specific standards for safety and usability. For companies like PreFab Inc., staying updated on local regulations is crucial; failure to comply can lead to costly delays or even project cancellations.

Moreover, understanding how these codes apply specifically to prefabricated units is vital. Many jurisdictions treat modular components differently from traditional builds, which can complicate approvals and inspections. PreFab Inc.'s proactive approach includes engaging with local authorities early in the design process to clarify requirements and streamline approval timelines.

The Importance of Compliance

Compliance isn’t just a bureaucratic box to tick; it’s a cornerstone of successful volumetric modular construction that protects both builders and occupants alike. Adhering to building codes ensures that every structure is safe, durable, and fit for purpose—qualities that potential clients prioritize when considering prefab options. Moreover, compliance fosters trust with stakeholders by demonstrating a commitment to quality standards.

In addition, navigating compliance effectively can also open doors for innovation within the industry. By understanding regulatory frameworks better than competitors do, PreFab Inc. can leverage its knowledge to create designs that not only comply but also push boundaries within those frameworks—ultimately leading to more efficient building processes without sacrificing safety or quality.

How PreFab Inc. is Leading the Way

PreFab Inc. stands at the forefront of overcoming regulatory challenges in volumetric modular construction through strategic partnerships and advocacy efforts. By collaborating closely with industry groups and regulatory bodies, PreFab Inc. helps shape policies that support innovation while maintaining safety standards in construction practices worldwide. This proactive stance allows them not only to navigate existing regulations but also to influence future ones favorably.

Additionally, PreFab Inc.’s commitment extends beyond compliance; they actively invest in training programs for their teams on current building codes related specifically to modular constructions. This ensures everyone involved—from designers to builders—is well-equipped with up-to-date knowledge about regulations affecting their work, directly impacting project success rates positively.

Lastly, by sharing best practices across the industry through forums or workshops led by their experts at PreFab Inc., they foster an environment where collaboration thrives rather than competition over compliance issues alone—ultimately benefiting all players involved in volumetric modular construction.

Conclusion

As we step into a new era of construction, it's clear that volumetric modular construction is not just a fleeting trend but a transformative approach reshaping the industry. With its ability to increase efficiency, reduce waste, and enhance design flexibility, this method is becoming the go-to solution for builders and developers alike. Companies like PreFab Inc. are at the forefront of this revolution, paving the way for a brighter, more sustainable future in construction.

Embracing the Future of Construction

The future of construction is undeniably tied to the rise of volumetric modular construction. This innovative approach allows for quicker project completion while maintaining high-quality standards—something that traditional methods often struggle to achieve. By embracing these advancements, companies can respond more adeptly to market demands and client needs.

Key Takeaways on Modular Trends

Several key trends are emerging within the realm of volumetric modular construction that deserve attention. First, sustainability is no longer optional; it’s imperative as builders seek eco-friendly materials and practices. Second, technological integration—such as digital twins and automation—is streamlining processes and enhancing precision in manufacturing.

The Path Forward for PreFab Inc.

Looking ahead, PreFab Inc. is poised to lead the charge in volumetric modular construction innovation. By focusing on collaboration with other industry leaders and investing in cutting-edge technologies, we aim to set new benchmarks for quality and efficiency in building projects worldwide. The path forward involves not only embracing current trends but also anticipating future needs within an ever-evolving landscape.