Introduction

In recent years, the construction industry has witnessed a significant transformation with the rise of volumetric construction. This innovative approach involves creating three-dimensional modules off-site and assembling them on location, offering a fresh perspective on how we think about building. With companies like PreFab Inc. leading the charge, volumetric construction is not just a trend; it's reshaping our urban landscapes and redefining efficiency.

The Rise of Volumetric Construction

Volumetric construction has emerged as a powerful solution to many challenges faced by traditional building methods. By prefabricating sections of structures in controlled environments, this technique minimizes waste and maximizes quality control, ultimately reducing project timelines and costs. As urbanization accelerates and housing demands soar, the appeal of volumetric construction becomes increasingly undeniable.

Why Innovation Matters

Innovation is the lifeblood of any industry, but in construction, it can mean the difference between stagnation and progress. Embracing new methods like volumetric construction allows firms to tackle issues such as labor shortages and rising material costs head-on. For PreFab Inc., prioritizing innovation not only enhances competitiveness but also helps create sustainable solutions that meet modern demands.

Key Drivers of Change

Several key drivers are propelling the shift toward volumetric construction in today's market. Technological advancements—such as 3D printing and robotics—are revolutionizing how we design and build structures, while increasing awareness around sustainability pushes for eco-friendly practices within the industry. Moreover, evolving consumer preferences for faster delivery times and customizable living spaces further accelerate this change towards volumetric solutions.

Understanding Volumetric Construction

Volumetric construction is revolutionizing the way we think about building design and execution. This innovative approach involves creating three-dimensional modules that are fabricated off-site and then assembled on location, resulting in a more efficient construction process. With its unique capabilities, volumetric construction is gaining traction as an alternative to traditional building methods.

Definition and Basics

At its core, volumetric construction refers to the practice of producing pre-fabricated modules that can be easily transported and assembled at the final site. These modules can include entire rooms or sections of buildings, allowing for rapid assembly and reduced on-site labor costs. PreFab Inc. has been at the forefront of this movement, demonstrating how volumetric construction can streamline project timelines while maintaining high quality.

One key aspect of volumetric construction is its modular nature; each unit is designed to fit seamlessly with others, creating a cohesive structure. This method not only enhances design flexibility but also allows for customization based on specific project needs. As we delve deeper into this topic, it's clear that understanding these foundational elements is crucial for appreciating the broader implications of volumetric construction.

Benefits Over Traditional Methods

The benefits of volumetric construction are numerous and compelling compared to traditional building methods. First and foremost, it significantly reduces construction time—projects can often be completed in half the time due to parallel processes in fabrication and site preparation. PreFab Inc.'s projects exemplify how accelerated timelines can lead to cost savings without compromising quality or safety.

Another advantage lies in enhanced precision; off-site fabrication minimizes errors typically encountered during on-site assembly. This leads to better overall quality control as components are manufactured under strict conditions in a controlled environment. Moreover, volumetric construction promotes sustainability by reducing waste through optimized material usage—a win-win for both builders and our planet!

Current Market Landscape

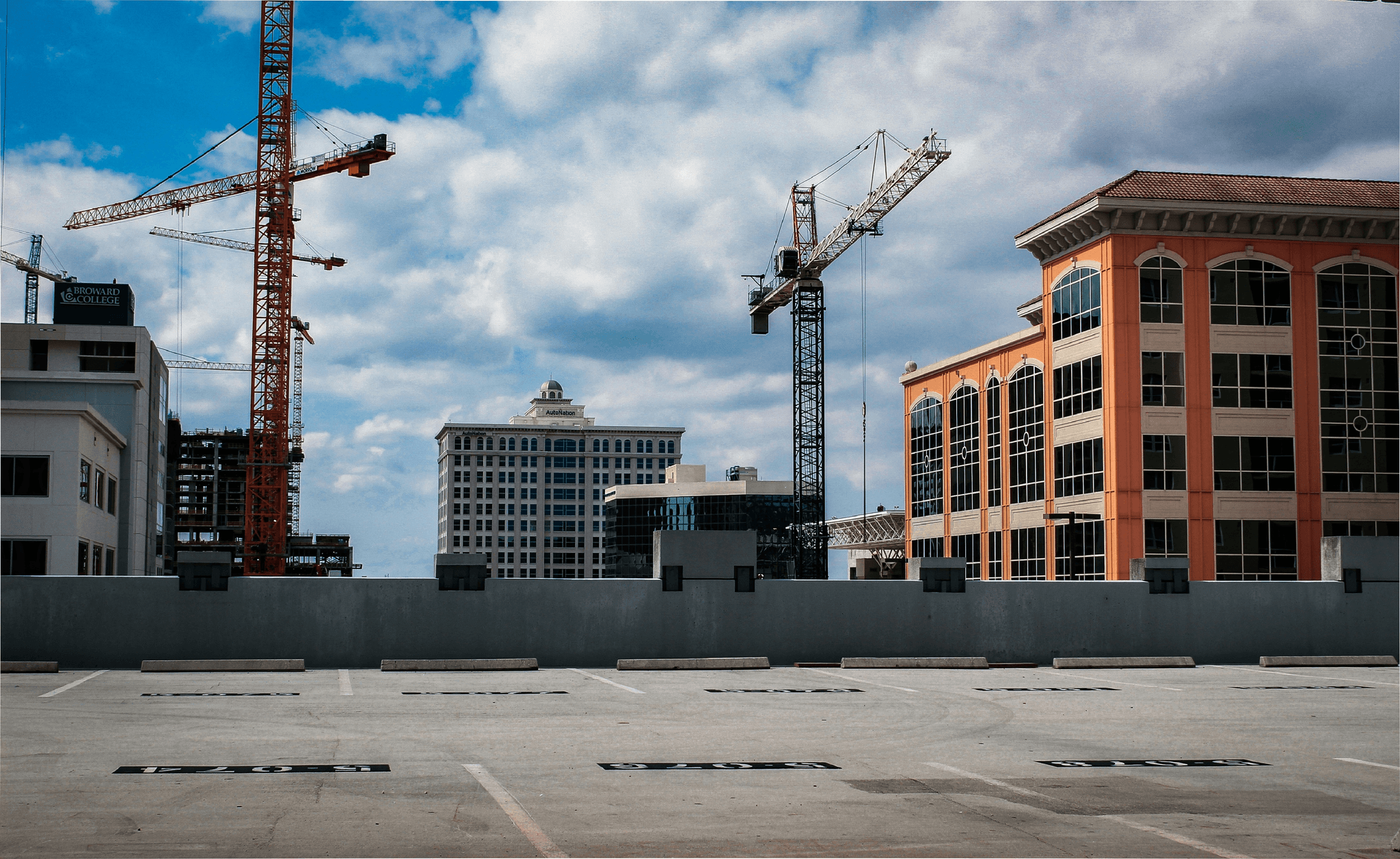

The current market landscape for volumetric construction reflects a growing acceptance among developers and contractors alike. As urbanization continues to rise globally, there’s an increasing demand for efficient housing solutions that meet both time constraints and budgetary limits—volumetric construction fits this bill perfectly! Companies like PreFab Inc., with their innovative approaches, are leading the charge in reshaping how we think about residential and commercial buildings.

Additionally, trends indicate that more industries are recognizing the potential of volumetric methods beyond just housing; sectors such as healthcare and education are exploring modular solutions too! With advancements in technology further enhancing these methods’ viability, it’s no surprise that investment in this area is steadily increasing as stakeholders seek out cost-effective alternatives to conventional building practices.

Technology Innovations in Volumetric Construction

The world of volumetric construction is undergoing a seismic shift, driven by groundbreaking technological innovations that are reshaping the industry. From 3D printing to robotics and virtual reality, these advancements are not just enhancing efficiency; they are redefining the very essence of how we build. PreFab Inc. stands at the forefront of this transformation, integrating cutting-edge technology into its projects to deliver superior results.

3D Printing Influence

3D printing has emerged as a game-changer in volumetric construction, allowing for unprecedented customization and speed in building processes. This technology enables companies like PreFab Inc. to create complex structures with intricate designs that were previously impossible or prohibitively expensive using traditional methods. With the ability to print entire building modules on-site or in controlled environments, 3D printing significantly reduces waste and accelerates project timelines.

Moreover, the use of 3D printing in volumetric construction opens up new avenues for sustainable practices by minimizing material consumption and energy usage during production. It also allows for rapid prototyping, enabling architects and builders to visualize their projects more effectively before committing to full-scale production. As this technology continues to evolve, we can expect even more innovative applications within the realm of volumetric construction.

Robotics and Automation

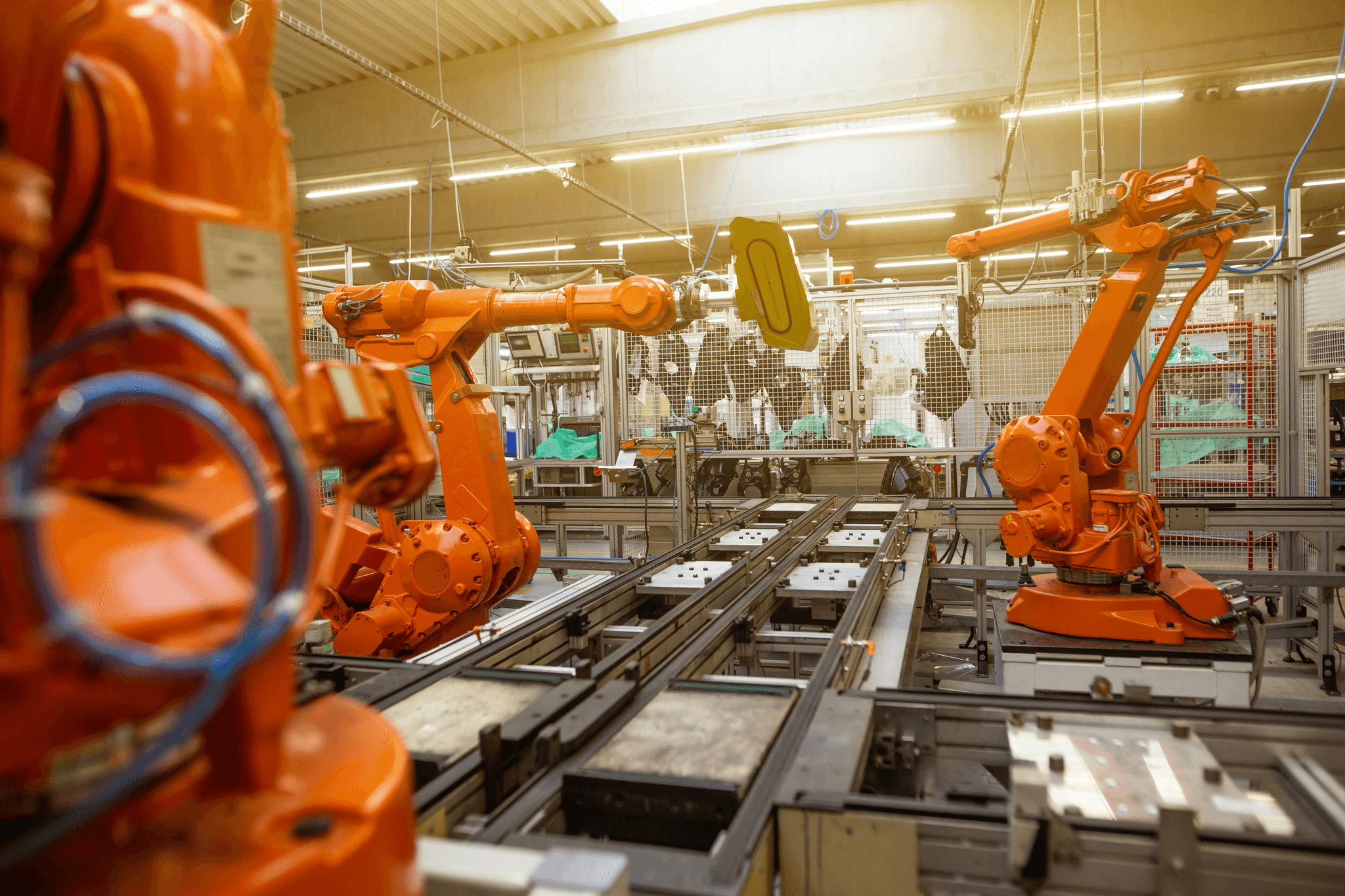

The integration of robotics and automation into volumetric construction is revolutionizing how buildings are assembled and completed. Automated systems can handle repetitive tasks with precision and speed that human workers simply cannot match, leading to increased productivity on job sites managed by firms like PreFab Inc. These technologies not only enhance efficiency but also improve safety by taking over hazardous tasks that would otherwise put workers at risk.

Robotics also plays a crucial role in quality control during the construction process, ensuring that each module meets strict standards before it leaves the factory floor or arrives at the site for assembly. The combination of robotics with volumetric construction techniques minimizes human error while maximizing output consistency—a win-win scenario for builders aiming for excellence in their projects. As automation becomes more sophisticated, we anticipate a future where robots will be indispensable partners on every job site.

Virtual Reality in Design

Virtual reality (VR) is transforming design processes within volumetric construction by providing immersive experiences that allow stakeholders to visualize projects before they break ground. With VR technology, clients can walk through virtual models created by PreFab Inc., gaining insights into spatial dynamics and design elements long before physical materials are used or labor begins. This capability fosters better communication among architects, engineers, clients, and builders—ensuring everyone is on the same page from day one.

Additionally, VR aids designers in identifying potential issues early on—saving time and resources down the line when modifications could be costly or disruptive if discovered late in development phases. As VR continues to develop alongside other technological innovations within volumetric construction practices, it promises an even brighter future where creativity meets functionality seamlessly—bringing imaginative visions to life with astonishing accuracy.

Sustainable Practices in Volumetric Construction

In the quest for a greener future, sustainable practices in volumetric construction are becoming increasingly vital. As the industry shifts towards more efficient methods, companies like PreFab Inc. are leading the charge by integrating eco-friendly solutions into their projects. By prioritizing sustainability, we can reduce environmental impact while still delivering high-quality structures.

Eco-Friendly Materials

One of the hallmarks of sustainable volumetric construction is the use of eco-friendly materials. These materials not only minimize harm to the environment but also enhance the overall lifecycle of a building. For instance, PreFab Inc. often utilizes recycled steel and sustainably sourced wood, which significantly reduces carbon footprints compared to traditional building materials.

Moreover, innovations in bioplastics and other renewable resources are paving the way for even more sustainable options in volumetric construction. By selecting materials that are both durable and environmentally friendly, builders can ensure that their projects align with modern sustainability goals. This commitment not only appeals to environmentally conscious consumers but also sets a new standard for future constructions.

Energy Efficiency Strategies

Energy efficiency is another critical component of sustainable volumetric construction practices. By designing buildings that maximize natural light and ventilation, companies like PreFab Inc. can significantly reduce energy consumption over time. Incorporating advanced insulation techniques and energy-efficient windows further enhances these efforts, making homes more comfortable while lowering utility bills.

Additionally, smart technology integration allows for real-time monitoring and management of energy usage within these structures. This not only optimizes performance but also empowers occupants to make informed decisions about their energy consumption habits. As energy efficiency becomes a priority in construction planning, it’s clear that volumetric construction is at the forefront of this revolution.

Waste Reduction Techniques

Waste reduction techniques play a pivotal role in enhancing sustainability within volumetric construction projects. The modular nature of this approach inherently minimizes waste by allowing for precise manufacturing processes off-site before assembly on-site—making it easier to manage resources effectively without compromising quality or design integrity.

PreFab Inc., for example, has implemented strategies such as reusing scrap materials from previous projects and adopting lean manufacturing principles to streamline production processes further. These initiatives not only cut down on waste but also contribute to cost savings—a win-win situation! With increased awareness surrounding waste management issues in construction, it's evident that embracing such techniques will be crucial for future developments in volumetric construction.

Case Studies of Successful Volumetric Construction

The world of volumetric construction is brimming with innovative examples that showcase its potential to revolutionize the building industry. By examining successful case studies, we can glean insights into how this method not only streamlines processes but also enhances quality and sustainability. Let's dive into some standout projects, including those by PreFab Inc., that highlight the transformative power of volumetric construction.

PreFab Inc. Projects Highlight

PreFab Inc. has been at the forefront of volumetric construction, leading the charge with several impressive projects that demonstrate its capabilities. One notable example is their modular housing development in a rapidly growing urban area, where they utilized volumetric units to create affordable yet stylish homes in record time. This project not only met housing demands but also showcased how PreFab Inc.'s approach can significantly reduce on-site labor costs while maintaining high standards of quality.

Another remarkable project by PreFab Inc. involved constructing a multi-story student residence using volumetric modules, which allowed for swift assembly and minimal disruption to campus life. The design incorporated eco-friendly materials and energy-efficient systems, aligning perfectly with contemporary sustainability goals. These projects underscore how PreFab Inc.'s commitment to innovation positions them as leaders in the evolving landscape of volumetric construction.

Notable Global Examples

Globally, there are numerous examples where volumetric construction has made waves beyond just local markets; they have set benchmarks for efficiency and creativity in building design. For instance, a prominent hotel chain recently adopted this method to construct an entire hotel in just a few months—an endeavor that would typically take over a year using traditional methods! This project not only emphasized speed but also highlighted how modular designs could enhance guest experiences through unique architectural features.

In another instance, an entire community was built using volumetric construction techniques in Sweden, showcasing sustainable living spaces designed for energy efficiency and minimal waste generation. Each unit was prefabricated off-site and assembled on location within days—a feat that would be unimaginable with conventional building practices! Such global examples illustrate the versatility and adaptability of volumetric construction across various sectors.

Lessons Learned from Successes

The successes seen in these case studies reveal several key lessons about the future of volumetric construction. First and foremost, collaboration between architects, engineers, and manufacturers is crucial for maximizing efficiency; when all parties work together from conception to completion, the results speak for themselves! Additionally, integrating technology—such as Building Information Modeling (BIM)—into planning phases can streamline processes further while reducing costly errors during assembly.

Furthermore, these projects highlight the importance of consumer engagement; understanding client needs allows for tailored designs that resonate well within communities while promoting sustainable living practices through innovative solutions like energy-efficient systems or eco-friendly materials used throughout constructions by companies like PreFab Inc.! Ultimately, these lessons pave the way for future advancements within this burgeoning field—one where creativity meets functionality through the lens of volumetric construction.

Future Predictions for Volumetric Construction

The future of volumetric construction is poised for significant transformation as various market trends, technologies, and consumer preferences converge. As the industry continues to evolve, it becomes essential to identify key areas that will shape its trajectory over the coming years. With companies like PreFab Inc. leading the charge, we can expect a dynamic landscape where innovation thrives.

Market Trends to Watch

One of the most compelling market trends in volumetric construction is the increasing demand for affordable housing solutions. As urbanization accelerates and populations grow, there’s a pressing need for efficient building methods that can deliver quality homes quickly and economically. Additionally, sustainability remains at the forefront, with consumers and developers alike prioritizing eco-friendly practices in their construction projects.

Another trend to keep an eye on is modular design's growing popularity within volumetric construction. This approach allows for flexibility in design while maintaining efficiency in production and assembly processes. As more stakeholders recognize the benefits of modularity—such as reduced waste and shorter build times—volumetric construction will likely gain even more traction.

Finally, government policies are increasingly supporting innovative construction methods, including volumetric approaches. Incentives aimed at sustainable development and affordable housing initiatives are paving the way for broader adoption of these techniques across various sectors. With PreFab Inc.'s commitment to innovation, they are well-positioned to capitalize on these favorable conditions.

Emerging Technologies on the Horizon

The integration of emerging technologies into volumetric construction promises to revolutionize how buildings are designed and constructed. One such technology is artificial intelligence (AI), which can optimize design processes and project management by analyzing vast amounts of data quickly and accurately. This capability not only enhances efficiency but also improves decision-making throughout a project's lifecycle.

Additionally, advancements in materials science will play a crucial role in shaping the future of volumetric construction. The development of smart materials that adapt to environmental conditions or enhance energy efficiency could lead to buildings that are not only more sustainable but also significantly cheaper to maintain over time. Companies like PreFab Inc., known for their innovative spirit, are likely already exploring these cutting-edge materials.

Lastly, augmented reality (AR) is set to transform how stakeholders visualize projects during planning stages in volumetric construction. By allowing clients and builders alike to experience designs before they’re built physically, AR helps mitigate misunderstandings while enhancing collaboration among teams involved in a project’s execution.

Shifts in Consumer Preferences

Consumer preferences are evolving rapidly as awareness around sustainability grows stronger among homeowners and investors alike. Today’s buyers often seek out environmentally responsible options when selecting new properties or renovations; thus making energy-efficient features vital within any new volumetric construction project attractive on the market today!

Moreover, there’s a noticeable shift toward personalization in home design; consumers want spaces that reflect their unique lifestyles rather than cookie-cutter models from traditional building practices! This demand opens up exciting opportunities for companies like PreFab Inc., which specializes in customizable solutions through its advanced modular designs—a perfect match for modern buyer expectations!

Finally—and perhaps most importantly—there's an increasing desire for community-focused developments that promote connectivity among residents while still providing individual spaces tailored specifically towards personal needs! Volumetric construction aligns perfectly with this trend by enabling developers not only to create aesthetically pleasing structures but also foster vibrant neighborhoods where people feel truly at home!

Conclusion

The future of construction is undeniably leaning towards volumetric construction, a method that promises efficiency, sustainability, and innovation. As we embrace this new era, it’s clear that the traditional building methods are being challenged by the benefits offered by volumetric techniques. The shift towards these innovative practices signifies not just a trend but a substantial evolution in how we think about and execute construction projects.

Embracing the Future of Construction

Embracing the future of construction means recognizing the transformative potential of volumetric construction. This approach allows for faster project completion times while ensuring high-quality standards through controlled manufacturing environments. By integrating advanced technologies and sustainable practices, we can create structures that not only meet current demands but also anticipate future needs.

The Role of PreFab Inc. in Innovation

PreFab Inc. is at the forefront of this revolution, driving innovation within the realm of volumetric construction. With our commitment to utilizing cutting-edge technology and sustainable materials, we are redefining how buildings are designed and constructed. Our projects exemplify the effectiveness of volumetric methods, showcasing how efficiency and creativity can coexist harmoniously in modern architecture.

Final Thoughts on Volumetric Construction Trends

In conclusion, as we look ahead to what lies beyond traditional building methods, it's clear that volumetric construction will play a pivotal role in shaping our built environment. The trends indicate a growing acceptance among consumers for these innovative solutions as they become more aware of their benefits—speed, sustainability, and cost-effectiveness all wrapped into one package! As companies like PreFab Inc. continue to lead the charge in this field, we can expect even more groundbreaking developments that will redefine what’s possible in construction.