Introduction

In a world where construction timelines stretch longer than a Monday morning, volumetric construction has emerged as a beacon of efficiency and innovation. This method, which involves prefabricating entire sections of buildings off-site before transporting and assembling them on location, is revolutionizing how we think about space and structure. Enter PreFab Inc., a trailblazer in this realm, harnessing the power of volumetric construction to redefine standards in the industry.

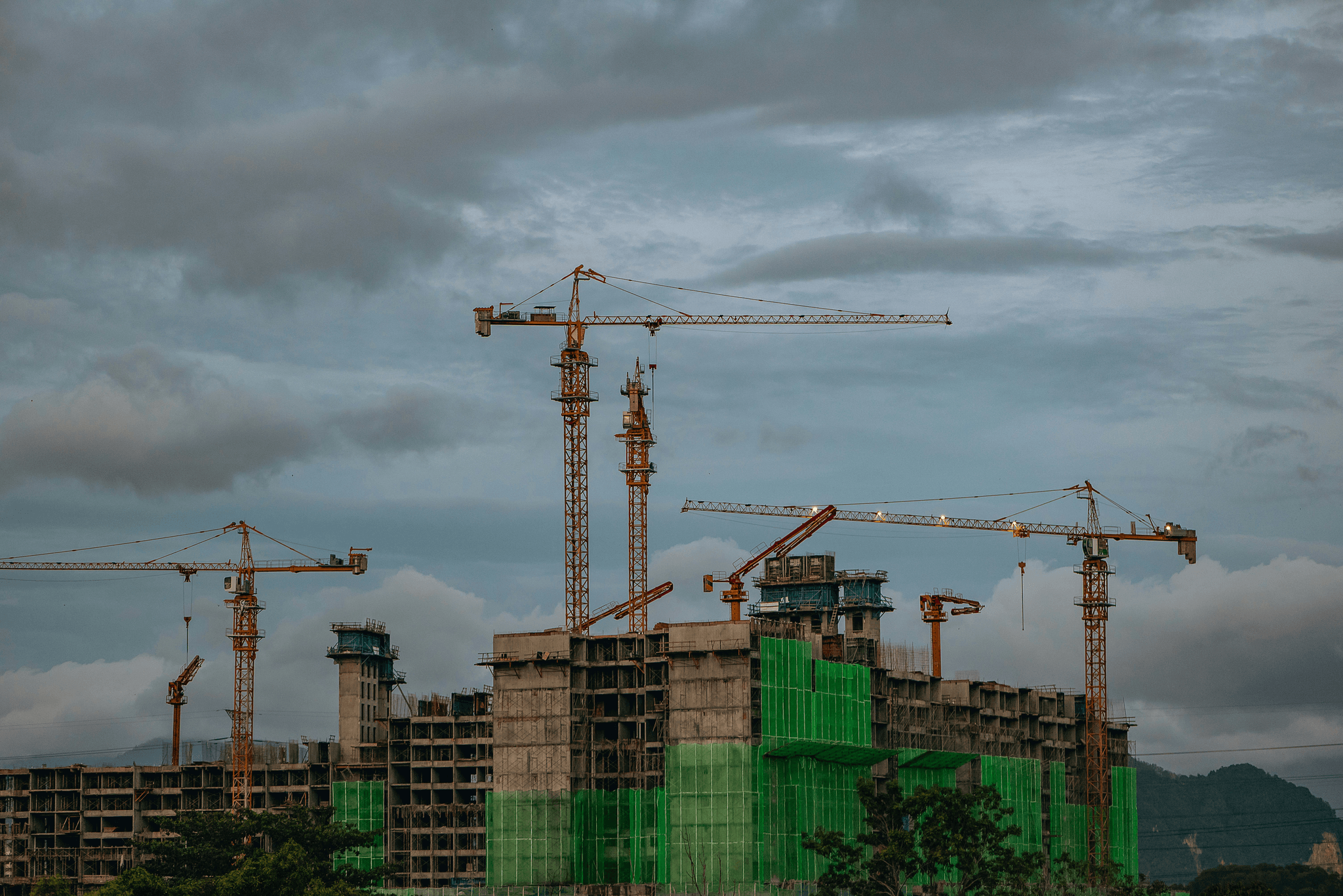

Understanding Volumetric Construction

Volumetric construction is not just a buzzword; it’s a transformative approach that reimagines traditional building practices. By creating modular units in controlled environments, this technique ensures precision and quality far superior to conventional methods. With volumetric construction, we can achieve remarkable speed without sacrificing structural integrity or aesthetic appeal.

The Rise of PreFab Inc.

PreFab Inc. has quickly risen to prominence as a leader in the realm of volumetric construction, setting benchmarks that others aspire to reach. With an unwavering commitment to quality and innovation, they have successfully completed numerous projects that showcase the versatility and effectiveness of this building method. As more developers recognize the advantages offered by PreFab Inc., their influence continues to grow exponentially within the industry.

Why It Matters for the Future

The significance of volumetric construction extends beyond mere efficiency; it holds profound implications for sustainable development and urban planning. As cities grapple with housing shortages and rising costs, solutions like those provided by PreFab Inc. become crucial for delivering affordable living options at scale. Embracing this methodology could very well shape our built environment for generations to come, making it an essential conversation for anyone invested in the future of construction.

What is Volumetric Construction?

Volumetric construction is revolutionizing how we approach building design and assembly, offering a fresh perspective on traditional methods. This innovative technique involves creating three-dimensional modules that can be prefabricated off-site and then transported to the construction location for quick assembly. With companies like PreFab Inc. leading the charge, volumetric construction is not just a trend; it’s shaping the future of the industry.

Definition and Key Concepts

At its core, volumetric construction refers to the process of fabricating entire sections or modules of a building in a controlled factory environment before transporting them to their final site. These modules are typically fully finished units that include walls, floors, and ceilings, ready for quick assembly upon arrival. Key concepts associated with volumetric construction include modularity, efficiency, and integration of services—essentially combining various elements into one cohesive unit.

How It Differs from Traditional Methods

Unlike traditional construction methods that often rely on sequential processes performed on-site, volumetric construction streamlines this by allowing for simultaneous work in a factory setting while site preparation occurs elsewhere. This approach drastically reduces time spent on-site and minimizes weather-related delays common in conventional building practices. Additionally, while traditional methods may involve significant labor costs associated with skilled tradespeople working on-site over extended periods, volumetric construction leverages automation and standardized components to enhance productivity.

Benefits of Volumetric Construction

The benefits of volumetric construction are numerous and compelling for both builders and clients alike. First off, it significantly lowers costs by reducing labor hours needed on-site and minimizing material waste through precise manufacturing processes at PreFab Inc.’s facilities. Moreover, speed is another major advantage; projects can be completed in weeks rather than months due to efficient assembly techniques that allow rapid installation once modules arrive at their destination—making it an attractive option for addressing urgent housing needs or commercial expansions.

The Advantages of Using PreFab Inc.

When it comes to the world of volumetric construction, PreFab Inc. stands out as a leader in innovation and efficiency. By leveraging advanced techniques and materials, the company has redefined what it means to build with speed and precision. In this section, we will explore how PreFab Inc. provides significant advantages through cost-effectiveness, rapid assembly, and rigorous quality control.

1. Cost-Effectiveness in Construction

One of the most compelling reasons to choose volumetric construction is its cost-effectiveness, a hallmark of PreFab Inc.'s approach. By utilizing prefabricated modules, the company minimizes material waste and reduces labor costs significantly compared to traditional building methods. This strategic focus on efficiency means that clients can achieve high-quality results without breaking the bank, making volumetric construction an attractive option for developers looking to maximize their budgets.

Moreover, with streamlined processes and bulk purchasing agreements for materials, PreFab Inc. can pass savings directly onto customers. The financial benefits extend beyond initial construction costs; reduced project timelines also translate into quicker returns on investment for developers and property owners alike. In a world where every dollar counts, choosing PreFab Inc.’s volumetric construction solutions can lead to substantial long-term savings.

2. Speed and Efficiency of Assembly

In today’s fast-paced market, time is money—something that PreFab Inc. understands all too well when it comes to volumetric construction projects. The use of prefabricated modules allows for simultaneous site preparation while units are being manufactured off-site, drastically cutting down overall project timelines. As a result, buildings can go from concept to completion much faster than conventional methods would allow.

This speed not only benefits developers but also helps meet urgent housing needs in communities facing shortages or crises—an area where volumetric construction shines brightly through initiatives led by PreFab Inc.. With quick assembly times without sacrificing quality or safety standards, clients can enjoy swift occupancy rates that keep pace with market demands. Efficiency in assembly is not merely about speed; it's about delivering value where it matters most.

3. Quality Control in Manufacturing

Quality assurance is paramount in any construction endeavor—and when it comes to volumetric construction at PreFab Inc., it's taken very seriously indeed! Each prefabricated module undergoes rigorous testing before leaving the factory floor to ensure that every aspect meets industry standards and client specifications perfectly. This level of quality control minimizes errors during installation on-site since components are designed to fit together seamlessly right out of the box.

Furthermore, manufacturing conditions allow for better oversight compared to unpredictable weather conditions faced during traditional builds; this ensures consistent quality across all units produced by PreFab Inc.. Clients can rest easy knowing their projects are built with precision craftsmanship that stands up against time—and potential challenges down the road! With such robust quality control measures in place within their volumetric construction framework, it's no wonder why so many choose PreFab Inc.

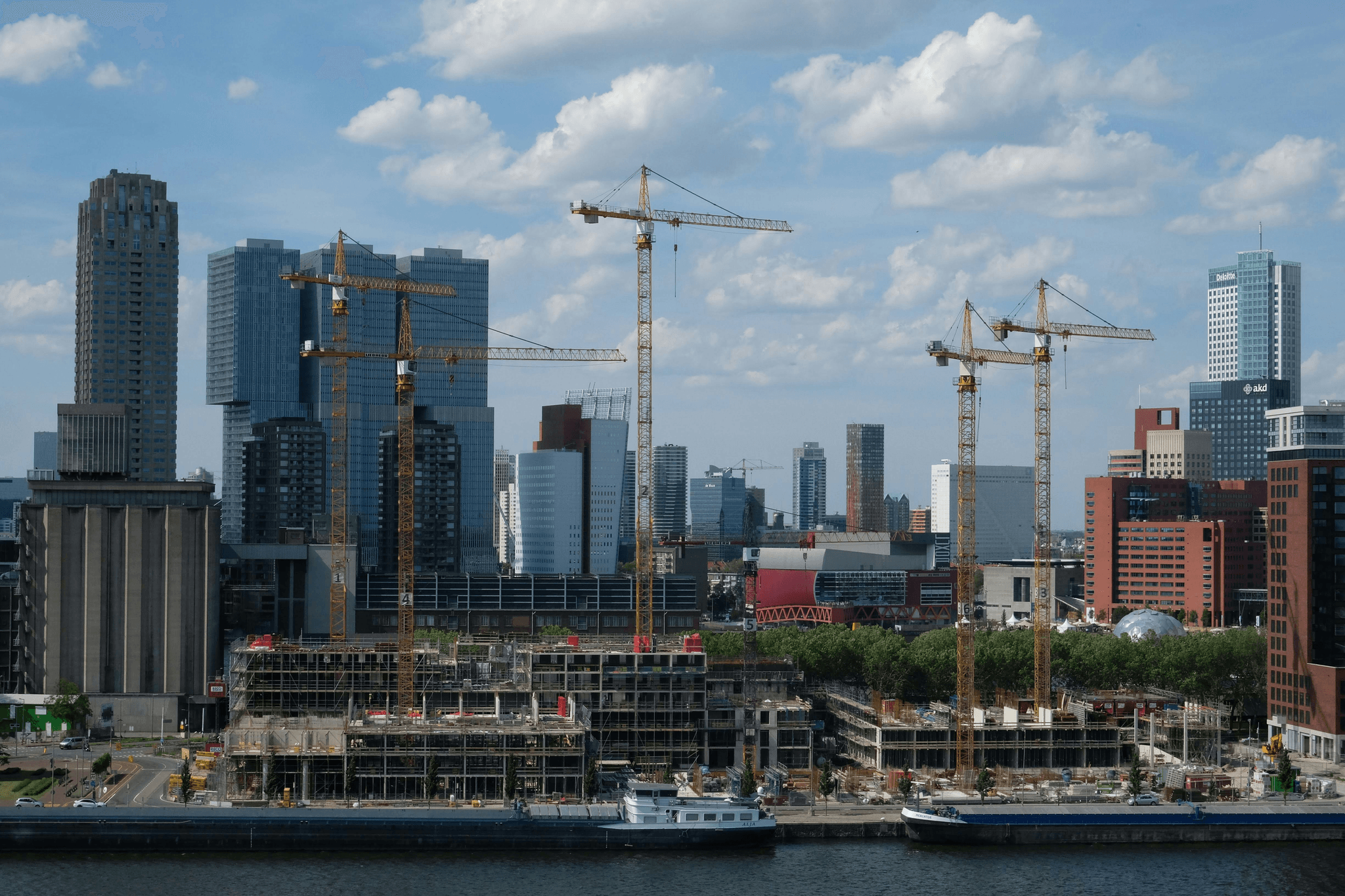

Real-World Applications of Volumetric Construction

Volumetric construction is not just a theoretical concept; it has tangible applications that are reshaping the built environment. PreFab Inc. has been at the forefront of this revolution, showcasing how modular designs can lead to innovative solutions across various sectors. From residential projects to commercial spaces, the versatility of volumetric construction is proving to be a game-changer.

Notable Projects by PreFab Inc.

PreFab Inc. has completed several notable projects that highlight the potential of volumetric construction. One standout example is their work on the Harmony Heights development, where entire housing units were constructed off-site and then assembled on location in record time. This project not only exemplifies speed and efficiency but also showcases how volumetric construction can create beautiful, functional living spaces with minimal disruption to local communities.

Another impressive feat is the transformation of urban landscapes through PreFab Inc.'s commercial projects, such as their collaboration on a high-rise office building in downtown Seattle. By employing volumetric construction techniques, they managed to reduce build time significantly while maintaining high standards of quality and design aesthetics. These projects serve as powerful case studies illustrating how volumetric construction can meet diverse needs while adhering to budget constraints.

Impact on Affordable Housing

One of the most pressing challenges in today's society is providing affordable housing, and volumetric construction offers a promising solution through companies like PreFab Inc. By utilizing modular designs and efficient assembly processes, they are able to produce housing units at a fraction of traditional costs without sacrificing quality or safety standards. This approach not only helps alleviate housing shortages but also makes homeownership more accessible for low- and middle-income families.

The impact extends beyond just affordability; it also fosters community development by creating neighborhoods that are thoughtfully designed and built quickly. In cities where housing demand outpaces supply, PreFab Inc.'s innovative use of volumetric construction can help bridge the gap between need and availability effectively. As these homes become available faster than conventional builds, families can find stability sooner rather than later.

Transforming Commercial Spaces

Volumetric construction isn't limited to residential applications; it's also making waves in commercial real estate thanks to PreFab Inc.'s pioneering efforts. Businesses are increasingly recognizing the benefits of modular buildings for offices, retail spaces, and even hospitality venues due to their rapid deployment capabilities and cost-effectiveness. This shift allows companies to adapt quickly in an ever-changing market while minimizing disruptions during renovations or new constructions.

For instance, PreFab Inc.’s recent project involved transforming an old warehouse into a vibrant co-working space using modular components designed for flexibility and scalability. The result was not only aesthetically pleasing but also functional for businesses looking for dynamic environments that foster collaboration and innovation—key elements in today's work culture influenced by remote working trends.

As we look at these real-world applications of volumetric construction spearheaded by PreFab Inc., it becomes clear that this method holds immense potential for addressing both current challenges in housing affordability and evolving commercial needs effectively.

Overcoming Challenges in Volumetric Construction

Volumetric construction is revolutionizing the building industry, but it doesn't come without its hurdles. Addressing misconceptions, navigating regulations, and implementing effective strategies are essential for PreFab Inc. and others looking to capitalize on this innovative approach. Let’s dive into how these challenges can be tackled head-on.

Addressing Misconceptions

One of the biggest challenges in volumetric construction is overcoming widespread misconceptions about its feasibility and quality. Many assume that modular structures lack aesthetic appeal or durability compared to traditional builds; however, this couldn’t be further from the truth. PreFab Inc.'s projects showcase that volumetric construction can produce stunning designs while maintaining structural integrity.

Additionally, there’s a belief that volumetric construction is only suitable for specific types of buildings, such as low-income housing or temporary structures. In reality, this method can be applied to a variety of projects—from luxury apartments to commercial spaces—proving its versatility and adaptability. By educating stakeholders about the true potential of volumetric construction, PreFab Inc. aims to dispel these myths and broaden acceptance across the industry.

Navigating Regulations and Standards

Navigating the complex web of regulations and building codes poses another significant challenge for volumetric construction advocates like PreFab Inc. Each region may have different standards regarding modular building practices, which can complicate project timelines and budgets if not addressed early on. Understanding local regulations is crucial for ensuring compliance while maximizing efficiency throughout the construction process.

Moreover, as more companies adopt volumetric methods, it becomes imperative to advocate for updated regulations that reflect contemporary building practices. This means working closely with policymakers to establish guidelines that support innovation without compromising safety or quality standards in volumetric construction projects. By actively participating in discussions around regulatory frameworks, PreFab Inc. can help shape a more favorable environment for future developments.

Strategies for Successful Implementation

To successfully implement volumetric construction techniques at scale, companies like PreFab Inc. need robust strategies tailored to their unique operational contexts. First and foremost is fostering collaboration among architects, engineers, contractors, and manufacturers from the outset of any project; this ensures everyone understands how their contributions fit into the larger picture of modular design and assembly.

Additionally, investing in advanced technologies such as Building Information Modeling (BIM) can enhance planning accuracy while streamlining communication among teams involved in a project’s lifecycle—from design through delivery—making it easier to manage timelines effectively within volumetric construction frameworks. Finally, continuous training programs will empower employees with knowledge about best practices related specifically to modular techniques so they feel confident executing their roles efficiently.

By addressing misconceptions surrounding modular builds while navigating regulatory landscapes strategically—and employing collaborative implementation tactics—PreFab Inc., along with other industry leaders embracing volumetric construction methods will pave the way for a brighter future in modern architecture.

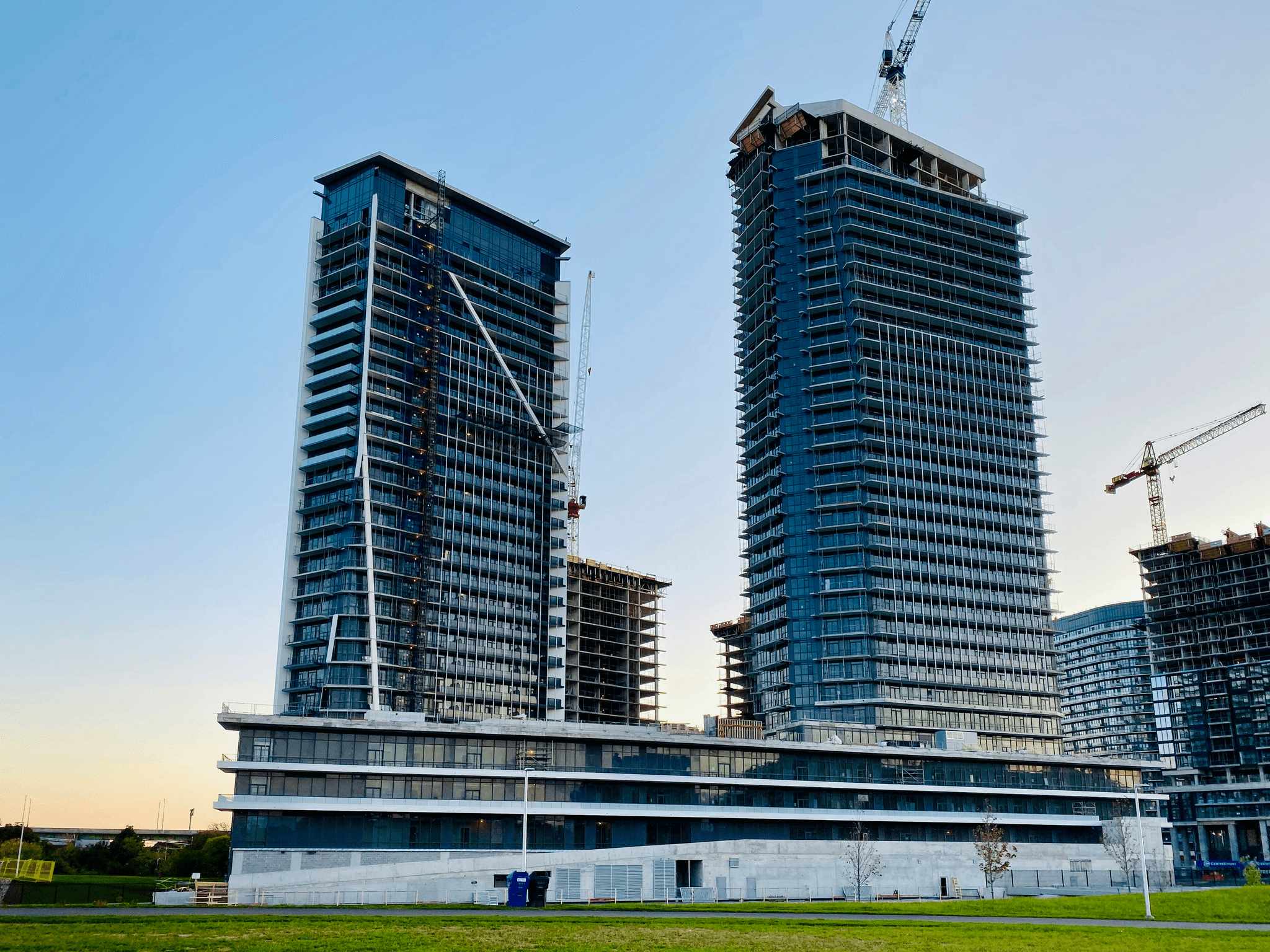

The Future of Volumetric Construction

As we look to the future, volumetric construction is poised for a transformative leap. With innovative approaches and advanced materials, the landscape of building design and execution is set to evolve dramatically. PreFab Inc. stands at the forefront of this evolution, ready to embrace new technologies and methodologies that will redefine how we think about construction.

Innovations on the Horizon

The next wave of innovations in volumetric construction promises to enhance both efficiency and creativity in building projects. Emerging technologies like 3D printing are being integrated into volumetric methods, enabling the production of intricate designs that were once deemed impossible. PreFab Inc. is already exploring these cutting-edge techniques, aiming to create modular units that not only meet but exceed current architectural standards.

Additionally, advancements in smart materials—those that can adapt or respond to environmental changes—will revolutionize how we approach energy efficiency in volumetric construction. Imagine buildings that can self-regulate temperature or even generate their own energy! With PreFab Inc.'s commitment to innovation, these futuristic concepts are quickly becoming reality.

Sustainability in Building Practices

Sustainability is no longer just a buzzword; it’s a necessity in today's construction industry. Volumetric construction inherently supports sustainable practices through reduced waste and lower carbon footprints compared to traditional methods. By utilizing off-site manufacturing processes, PreFab Inc. minimizes material waste while ensuring each component is crafted with precision.

Moreover, the ability to integrate renewable energy solutions directly into modular units allows for more environmentally friendly buildings from the ground up. This not only addresses ecological concerns but also appeals to a growing market demand for sustainable living spaces. As society shifts towards greener practices, PreFab Inc.’s focus on sustainability positions it as a leader in this essential movement within volumetric construction.

The Role of Technology in Evolution

Technology plays a pivotal role in shaping the future of volumetric construction by streamlining processes and enhancing collaboration among stakeholders. Building Information Modeling (BIM) has already changed how architects and builders interact with design plans, allowing for real-time adjustments that save time and reduce errors during assembly phases at PreFab Inc.'s facilities.

Furthermore, automation and robotics are set to take center stage in manufacturing modular components, significantly speeding up production times while maintaining high-quality standards synonymous with volumetric construction projects by PreFab Inc.. As these technologies continue to advance, they will further solidify volumetric methods as not just an alternative but perhaps the preferred choice for modern building solutions.

Conclusion

In the ever-evolving landscape of construction, embracing change is not just a trend; it’s a necessity. Volumetric construction represents a paradigm shift, offering innovative solutions that cater to modern demands for efficiency and sustainability. Companies like PreFab Inc. are at the forefront of this transformation, showcasing how adaptability can lead to remarkable advancements in building practices.

Embracing Change in Construction

The construction industry has long been resistant to change, but the rise of volumetric construction is challenging that status quo. By adopting modular techniques, builders can streamline processes and reduce waste while enhancing quality control. PreFab Inc.'s commitment to innovation exemplifies how embracing these new methods can lead to significant benefits for both developers and end-users.

The Growing Demand for Volume Solutions

As urban populations swell and housing shortages become more pronounced, the demand for volume solutions has never been higher. Volumetric construction offers a way to meet these challenges head-on by providing affordable housing options without compromising on quality or design. PreFab Inc.'s projects are a testament to how this approach not only satisfies market needs but also paves the way for future developments.

How PreFab Inc. is Leading the Way

PreFab Inc. stands out as a leader in volumetric construction by continuously pushing boundaries and setting new standards within the industry. Their innovative designs and efficient assembly processes demonstrate that modular building isn’t just about speed; it’s about creating sustainable spaces that enhance community living. With their forward-thinking approach, PreFab Inc. is not just responding to current trends but actively shaping the future of construction.