Introduction

In recent years, prefabricated building structures have gained immense popularity due to their efficiency and versatility. These structures are manufactured off-site and assembled on location, offering a streamlined approach to construction that can save both time and resources. However, while the benefits are significant, understanding the nuances of safety in prefabrication is equally critical.

Understanding Prefabricated Building Structures

Prefabricated building structures refer to components that are created in a factory setting before being transported to the construction site for assembly. This method allows for greater precision and quality control, leading to enhanced durability and performance. As we delve into this topic, it’s essential to grasp how these components work together to create safe living and working environments.

The Importance of Safety in Construction

Safety should always be a top priority in any construction project, including those involving prefabricated building structures. The unique aspects of prefabrication introduce specific safety considerations that must be addressed throughout the entire process—from design through installation and beyond. When you prioritize safety, you not only protect workers but also ensure the longevity and integrity of the structure itself.

An Overview of Prefab Building Safety Tips

Navigating the realm of prefab construction requires an understanding of best practices for safety at every stage. From selecting high-quality materials to ensuring proper site preparation and assembly techniques, there are numerous factors that contribute to a secure build. At PreFab Inc., we emphasize these safety tips as essential guidelines for anyone involved in creating or managing prefabricated building structures.

Materials Matter: Choosing the Right Components

When it comes to prefabricated building structures, the choice of materials is paramount. Selecting high-quality components can mean the difference between a sturdy, safe structure and one that may pose risks down the line. In this section, we'll explore why quality should trump cost, popular materials used in prefabrication, and how material quality directly impacts safety.

Quality over Cost in Prefabricated Structures

In the world of construction, especially with prefabricated building structures, the adage you get what you pay for rings especially true. While it might be tempting to cut corners and opt for cheaper materials to save a few bucks upfront, this can lead to significant safety issues later on. Investing in high-quality components from reputable suppliers like PreFab Inc. ensures that your structure stands strong against environmental challenges and lasts longer without requiring extensive repairs.

Quality materials not only enhance durability but also contribute to overall safety by reducing risks associated with structural failures. When you prioritize quality over cost in your prefabricated building structure, you're essentially investing in peace of mind—knowing that your project is built on a solid foundation with reliable components. Remember, skimping on materials might save money now but could lead to costly problems later.

Popular Materials in Prefabrication

Prefabricated building structures often utilize a mix of traditional and innovative materials tailored for efficiency and strength. Some popular choices include steel framing for its superior strength-to-weight ratio, engineered wood products for sustainability and versatility, and concrete panels for their fire resistance and durability. Each material has its unique benefits that cater to various needs within the realm of prefabrication.

Moreover, advancements in technology have led to new composite materials that are both lightweight and incredibly strong—perfect for modern prefabricated designs! PreFab Inc.'s range of offerings includes these cutting-edge materials as well as time-tested options that have proven their worth over decades of use in construction projects worldwide. Understanding these options is crucial when planning your next project; choosing wisely could elevate your prefabricated building structure from ordinary to extraordinary.

Impact of Material Quality on Safety

The link between material quality and safety cannot be overstated when discussing prefabricated building structures. High-quality materials are less likely to degrade over time or succumb to environmental stressors like moisture or pests—factors that can compromise structural integrity significantly. For instance, using premium-grade steel can prevent rusting issues commonly found with inferior alternatives while ensuring robust support throughout the lifespan of your build.

Furthermore, poor-quality materials can lead to hidden dangers such as mold growth or compromised insulation properties which may not become apparent until it's too late. Regular inspections combined with high-quality material choices help mitigate these risks effectively; thus making it essential for builders like PreFab Inc., who prioritize safety above all else during every phase of construction—from selection through assembly! Ultimately, investing in superior components pays dividends by safeguarding both lives and investments alike within any prefabricated building structure.

Design Considerations for Safety

When it comes to prefabricated building structures, design is not just about aesthetics; it's a crucial component of safety. A well-thought-out design can mitigate risks and enhance the durability of the structure, ensuring it withstands various environmental challenges. By focusing on safety during the design phase, we can create prefabricated buildings that are not only visually appealing but also robust and secure.

Lessons from Iconic Prefab Designs

Looking at iconic prefabricated building structures throughout history can provide valuable insights into safe design practices. For example, the famous Case Study Houses in California exemplify how innovative designs can lead to both beauty and structural integrity. These designs prioritize functionality while incorporating safety features that have stood the test of time, reminding us that good looks and safety need not be mutually exclusive.

One standout lesson is that flexibility in design allows for adaptations based on local climate conditions and potential hazards. This adaptability ensures that a prefabricated building structure can remain safe even in unpredictable weather patterns or seismic zones. At PreFab Inc., we take these lessons to heart, integrating smart design practices into all our projects to ensure maximum safety without sacrificing style.

Ensuring Structural Integrity through Design

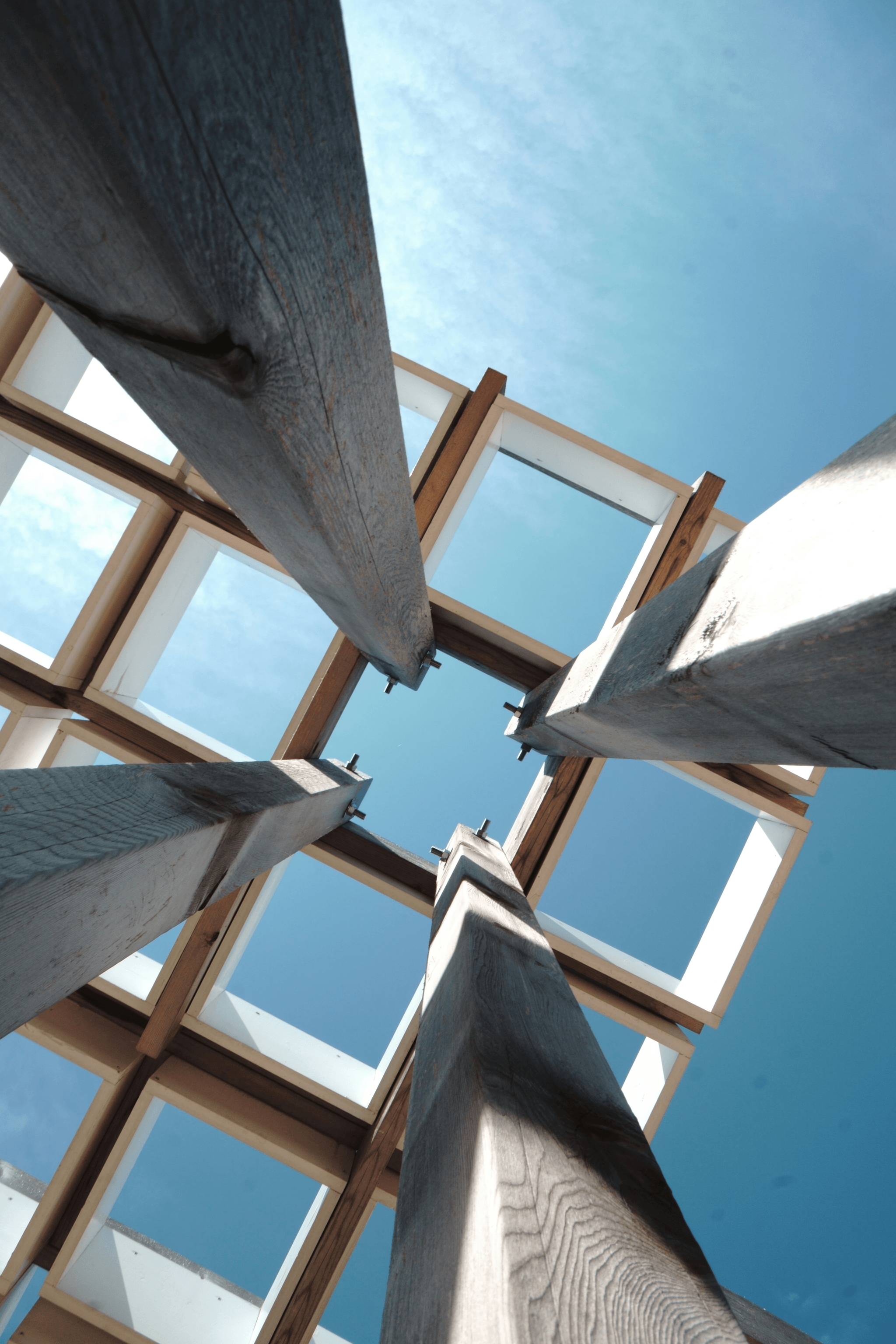

Structural integrity is paramount when constructing any prefabricated building structure; it’s what keeps everything standing tall and proud! A well-designed prefab must account for load distribution, material strengths, and potential stress points throughout its lifecycle. Engineers play a vital role here by employing advanced modeling techniques to predict how different elements will interact under various conditions.

Using high-quality materials is essential for achieving this structural integrity—something we emphasize at PreFab Inc.—but so is thoughtful design. Features like cross-bracing or reinforced corners help ensure stability while allowing for aesthetic appeal in the overall look of the structure. By prioritizing these elements during the planning phase, we create safer environments where occupants feel secure.

The Role of Engineers in Safety

Engineers are often seen as the unsung heroes behind every successful prefabricated building structure; their expertise ensures safety from concept to completion! They assess every aspect—from material selection to load calculations—to guarantee that each element works harmoniously together while conforming to local regulations and standards. Their commitment doesn't stop once construction begins; they’re involved throughout assembly and installation phases as well.

At PreFab Inc., our engineers collaborate closely with architects to fuse creativity with technical precision, creating designs that prioritize both aesthetics and safety features seamlessly integrated into each project’s framework. This teamwork results in buildings designed not only for beauty but also resilience against natural disasters or wear over time—making them a smart investment for any owner looking for long-lasting performance.

In summary, thoughtful design considerations combined with engineering expertise are vital components of ensuring safety in prefabricated structures—a philosophy embedded deeply within our ethos at PreFab Inc.

Site Preparation and Foundations

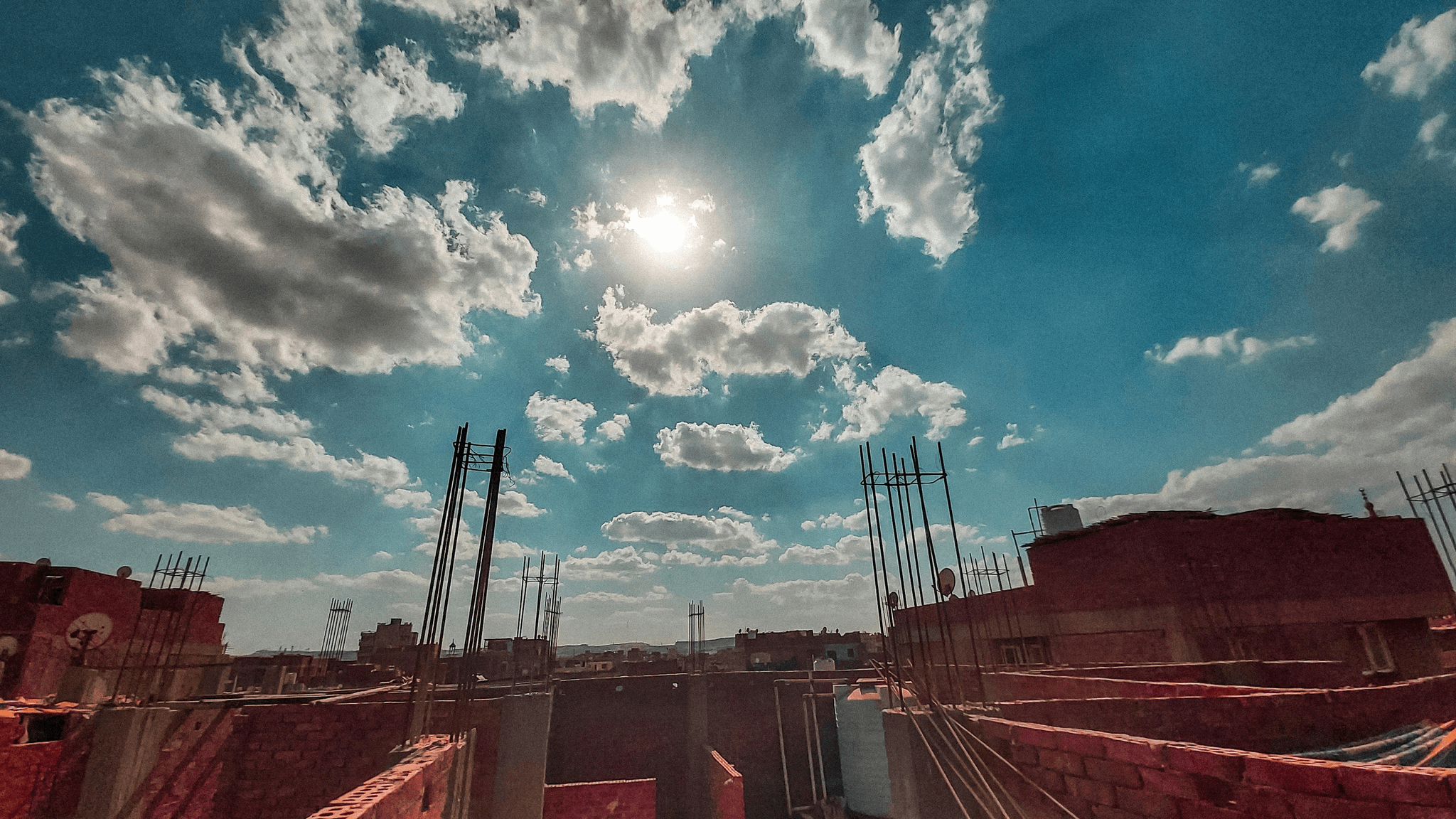

When it comes to constructing a prefabricated building structure, site preparation and foundation work are critical steps that set the tone for safety and durability. A solid foundation is not just a matter of aesthetics; it’s about ensuring that your prefab structure stands the test of time and elements. If you want your prefabricated building to be secure, investing time in proper site preparation is non-negotiable.

Best Practices for Site Assessment

Before laying down any concrete or assembling a prefabricated building structure, conducting a thorough site assessment is essential. This means evaluating the topography, drainage patterns, and existing vegetation to ensure the land can support your new build. Engaging professionals who specialize in site assessments can help identify potential hazards or challenges that could impact both safety and construction timelines.

A well-executed site assessment will also consider local zoning laws and regulations—because no one wants a surprise visit from the authorities after their prefab has been installed! PreFab Inc. recommends collaborating with experienced surveyors who can provide insights into the best layout for your prefabricated building structure while adhering to compliance standards. Ultimately, this groundwork will pave the way for successful assembly down the line.

Common Foundation Techniques for Prefab Buildings

Once you've assessed your site, it’s time to think foundations! The type of foundation you choose for your prefabricated building structure greatly influences its stability and longevity. Some popular techniques include slab-on-grade foundations, crawl spaces, or even piers—each offering unique benefits depending on soil conditions and climate.

For example, slab-on-grade foundations are often favored in warmer climates where frost heave isn’t a concern; they provide excellent support without breaking the bank. On the other hand, pier foundations elevate your prefab off the ground, making them ideal for areas prone to flooding or heavy rains. Whichever method you choose, make sure it aligns with both safety standards and local building codes—after all, nobody wants their dream home turning into a sinking ship!

Importance of Soil Testing

Soil testing might sound like an extra step that could be skipped—but trust us when we say it's crucial when dealing with any prefabricated building structure! The soil's load-bearing capacity determines how well your foundation will perform under pressure; if it's too weak or unstable, you're setting yourself up for future headaches (and maybe even structural failure).

Conducting soil tests before construction helps identify issues like high moisture content or expansive clay that could compromise stability over time. PreFab Inc. strongly advises not to overlook this step—investing in comprehensive soil testing can save you from costly repairs later on while enhancing overall safety during construction and beyond!

Assembly and Installation Practices

When it comes to assembling a prefabricated building structure, the process can be as crucial as the design and materials used. The assembly phase is where all the planning and preparation come together, and doing it right ensures not only safety but also longevity. Whether you’re considering professional help or a DIY approach, understanding the implications of each choice is vital.

Professional vs. DIY: Safety Implications

Choosing between professional assembly and a DIY approach for your prefabricated building structure can significantly impact safety outcomes. Professionals bring expertise, experience, and often a keen eye for detail that can prevent costly mistakes during installation. On the other hand, while DIY may seem cost-effective, it could lead to safety hazards if not executed properly—after all, it's not just about putting pieces together; it's about ensuring structural integrity.

Hiring professionals like PreFab Inc. means you’re investing in peace of mind—these experts know the ins and outs of prefabricated structures and can navigate any challenges that arise during assembly. They are equipped with the right tools and knowledge to adhere to safety standards that might be overlooked in a DIY scenario. Ultimately, while there’s satisfaction in building something yourself, when it comes to safety in construction, sometimes it’s best to leave it to those who do this every day.

Step-by-Step Assembly Guidelines

To ensure your prefabricated building structure is assembled safely and efficiently, following step-by-step guidelines is essential. Start by reviewing all components included in your prefab kit; make sure nothing is missing before you begin assembly. Next, prepare your site according to previously established plans—this includes leveling the ground and ensuring proper access for delivery trucks.

Once everything is ready, lay out each section of your prefabricated building structure according to the manufacturer’s instructions—think of this as laying out puzzle pieces before putting them together! As you begin assembly, always check for alignment using levels or plumb lines; this will help maintain structural integrity throughout the process. Remember that patience pays off; rushing through these steps can lead to mistakes that compromise safety down the line.

Finally, once assembled, conduct thorough inspections at each stage before moving on; this practice ensures any potential issues are caught early on rather than after everything is put together—a classic case of “measure twice, cut once.” If you encounter any uncertainties during assembly or installation of your prefabricated building structure, don’t hesitate to reach out for assistance from professionals at PreFab Inc., who can provide guidance tailored specifically for your project.

Common Mistakes in Prefabricated Installation

Even seasoned builders can fall prey to common mistakes when installing a prefabricated building structure—awareness is half the battle! One frequent error involves neglecting proper site preparation; without an adequately prepared foundation or level ground surface, even high-quality materials won't perform optimally over time. Another common pitfall is ignoring local regulations regarding height restrictions or setbacks—be sure you're compliant before proceeding with installation!

Moreover, misalignment during assembly often leads to serious structural issues later on; taking shortcuts here could mean significant headaches down the road (and possibly some expensive repairs). It's also important not to overlook ventilation requirements specific to different types of prefab structures; inadequate airflow can lead not only to discomfort but also long-term damage due to moisture buildup within walls or ceilings.

Lastly—and perhaps most importantly—ensure everyone involved understands their roles clearly throughout every phase of installation! Communication lapses among team members can result in confusion that ultimately jeopardizes both safety standards and project timelines when constructing your prefabricated building structure. By recognizing these common mistakes ahead of time and addressing them proactively with guidance from experts like PreFab Inc., you'll be well on your way toward achieving a safe and successful build!

Regular Maintenance and Inspections

Maintaining a prefabricated building structure is crucial for ensuring its longevity and safety. Regular inspections can help identify potential issues before they escalate, saving you time, money, and stress in the long run. At PreFab Inc., we believe that a proactive approach to maintenance is the best way to protect your investment.

The Safety Checklist for Prefabricated Structures

Creating a safety checklist for your prefabricated building structure is an essential step in maintaining its integrity. Start by inspecting the exterior for any signs of wear or damage, such as cracks or leaks in the walls and roof. Don’t forget to check the foundation; it should be level and free from any signs of shifting or erosion.

Next, examine all doors and windows to ensure they open and close properly, which not only contributes to energy efficiency but also enhances security. Inspect electrical systems for frayed wires or exposed connections—safety first! Finally, make sure that all safety equipment, such as fire extinguishers and smoke detectors, are functional and up-to-date.

Importance of Routine Maintenance

Routine maintenance of your prefabricated building structure cannot be overstated; it’s like giving your building a regular health check-up! Just as you wouldn’t skip annual physicals, your prefab needs consistent care to remain safe and functional. By adhering to a regular maintenance schedule, you can extend the lifespan of materials used in construction while ensuring compliance with safety regulations.

Moreover, maintaining your structure helps prevent small issues from turning into costly repairs down the line. This proactive approach not only saves money but also enhances the comfort of those using the space—nobody wants to deal with unexpected leaks or structural problems when they could have been easily avoided! So roll up those sleeves; routine maintenance is essential!

Signs that Your Prefab Needs Attention

Knowing when your prefabricated building structure needs attention can save you headaches later on. Keep an eye out for warning signs such as unusual sounds (creaks or pops) during temperature changes—this could indicate structural shifts that require immediate attention. Additionally, if you notice water stains on walls or ceilings, it’s time to investigate potential leaks before they lead to mold growth.

Another red flag is if doors or windows start sticking; this may indicate movement within the structure that could compromise its integrity over time. Lastly, don’t ignore any persistent odors—unpleasant smells can signal hidden issues like mold or poor ventilation that need addressing promptly. Remember: staying vigilant now means fewer worries later!

Conclusion

In wrapping up our exploration of prefabricated building structures, it's essential to highlight the critical elements that contribute to safety and longevity. From selecting high-quality materials to ensuring proper design and installation practices, each aspect plays a vital role in the overall integrity of these structures. Remember, the journey doesn't end once your prefab is assembled; ongoing maintenance and inspections are paramount for continued safety.

Key Takeaways for Safe Prefabrication

When it comes to prefabricated building structures, prioritizing quality over cost is non-negotiable. Utilizing durable materials not only enhances safety but also extends the life of your structure, ensuring it stands the test of time. Additionally, involving experienced engineers during the design phase can prevent costly mistakes down the road and bolster structural integrity.

The Future of Prefabricated Building Safety

The landscape of prefabricated building structures is evolving rapidly with advancements in technology and construction practices. Innovations such as smart materials and improved engineering software promise to enhance safety measures significantly in future projects. As we look ahead, collaboration between manufacturers like PreFab Inc., architects, and engineers will be crucial in developing standards that further elevate safety across all prefab constructions.

How PreFab Inc. Can Help You Stay Safe

At PreFab Inc., we understand that ensuring safety in prefabricated building structures goes beyond just providing quality components; it involves a holistic approach from planning through maintenance. Our team offers expert guidance on material selection, design considerations, and assembly practices tailored to your specific needs. With our commitment to excellence and safety-first philosophy, you can trust us to be your partner in creating safe and sustainable living spaces.