Introduction

In recent years, prefab steel construction has emerged as a game-changer in the building industry, revolutionizing how structures are conceived and erected. This innovative approach not only streamlines the construction process but also offers significant advantages in terms of sustainability and design flexibility. As urban landscapes evolve, the demand for efficient and versatile building solutions continues to rise, positioning prefab steel at the forefront of modern construction.

The Rise of Prefab Steel Construction

The rise of prefab steel construction can be attributed to its ability to meet the increasing demands for speed and efficiency in building projects. With advancements in technology and a growing emphasis on sustainability, more developers are turning to prefab solutions to minimize waste and reduce project timelines. Companies like PreFab Inc. are leading this charge by providing high-quality prefab steel components that cater to various architectural needs.

What’s Driving Innovation in Construction?

Several factors are driving innovation in construction today, with a notable shift towards automation and smart technologies playing a pivotal role. The integration of robotics, 3D printing, and artificial intelligence is reshaping traditional methods, making them faster and more efficient than ever before. As these innovations take hold, they create new opportunities for companies like PreFab Inc., allowing them to push the boundaries of what’s possible with prefab steel construction.

Key Benefits of Prefab Steel

Prefab steel construction offers a multitude of benefits that make it an attractive option for builders and developers alike. Not only does it provide enhanced durability and strength compared to traditional materials, but it also allows for greater design flexibility without compromising structural integrity. Additionally, with reduced labor costs and shorter project timelines, investing in prefab steel is proving to be both economically savvy and environmentally responsible—an essential combination in today’s competitive market.

Advances in Technology

The construction industry is rapidly evolving, and at the forefront of this transformation are advances in technology that enhance prefab steel construction. With innovations like 3D printing, robotics, and smart building technologies, the efficiency and effectiveness of construction processes are reaching new heights. Companies like PreFab Inc. are leveraging these advancements to redefine how structures are designed and built.

3D Printing in Construction

3D printing is revolutionizing prefab steel construction by allowing for the rapid creation of complex components with precision and minimal waste. This technology enables builders to produce customized elements on-site or at a nearby facility, significantly reducing lead times and transportation costs. By integrating 3D printing into their workflow, PreFab Inc. can offer clients unique designs that meet specific needs without compromising quality or durability.

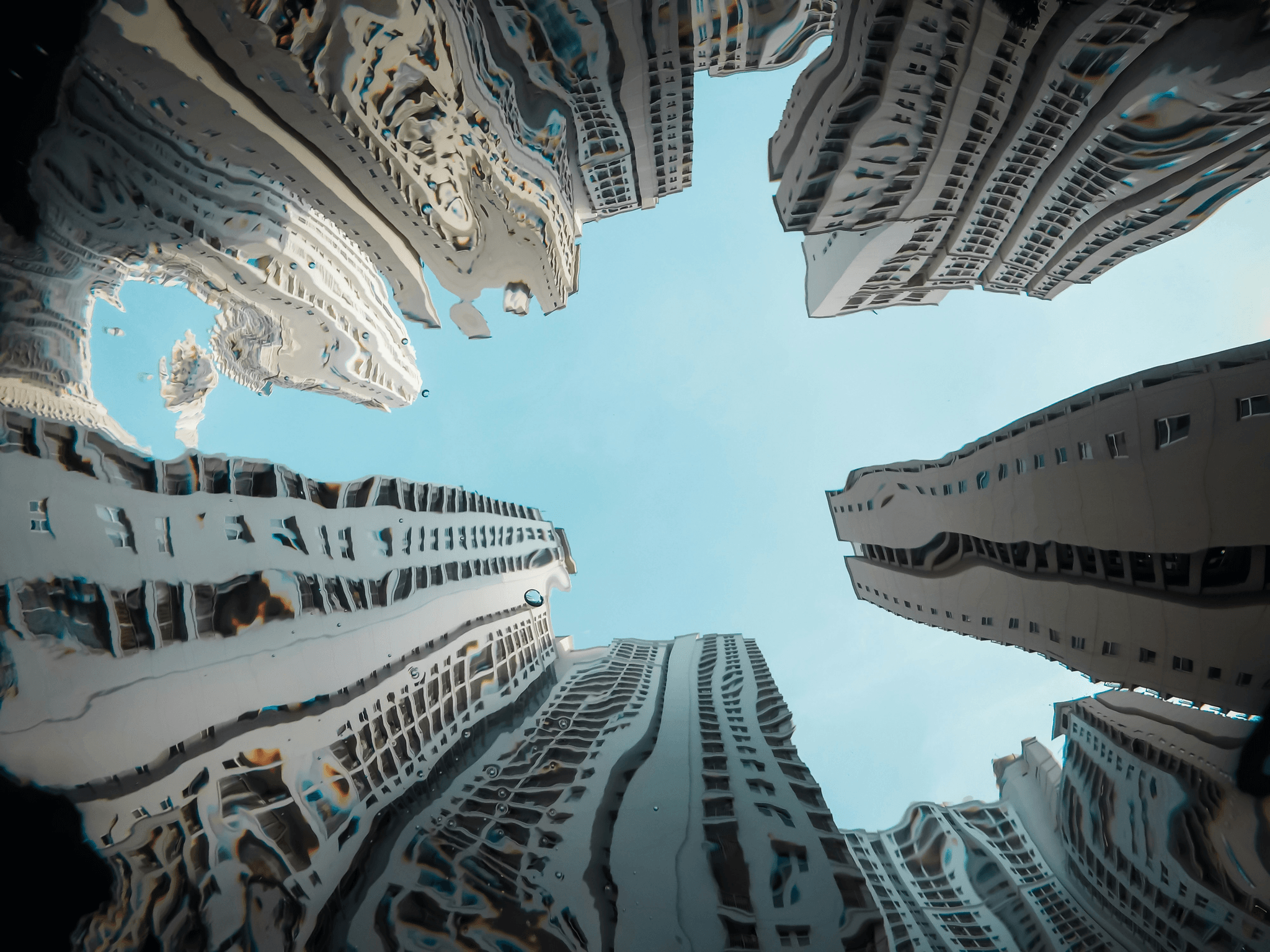

Moreover, the ability to create intricate designs with 3D printing means architects can explore innovative shapes previously thought impractical for steel structures. The adaptability of this technology not only enhances aesthetic appeal but also contributes to structural integrity by optimizing material use. As a result, prefab steel construction becomes more sustainable and cost-effective while pushing the boundaries of design possibilities.

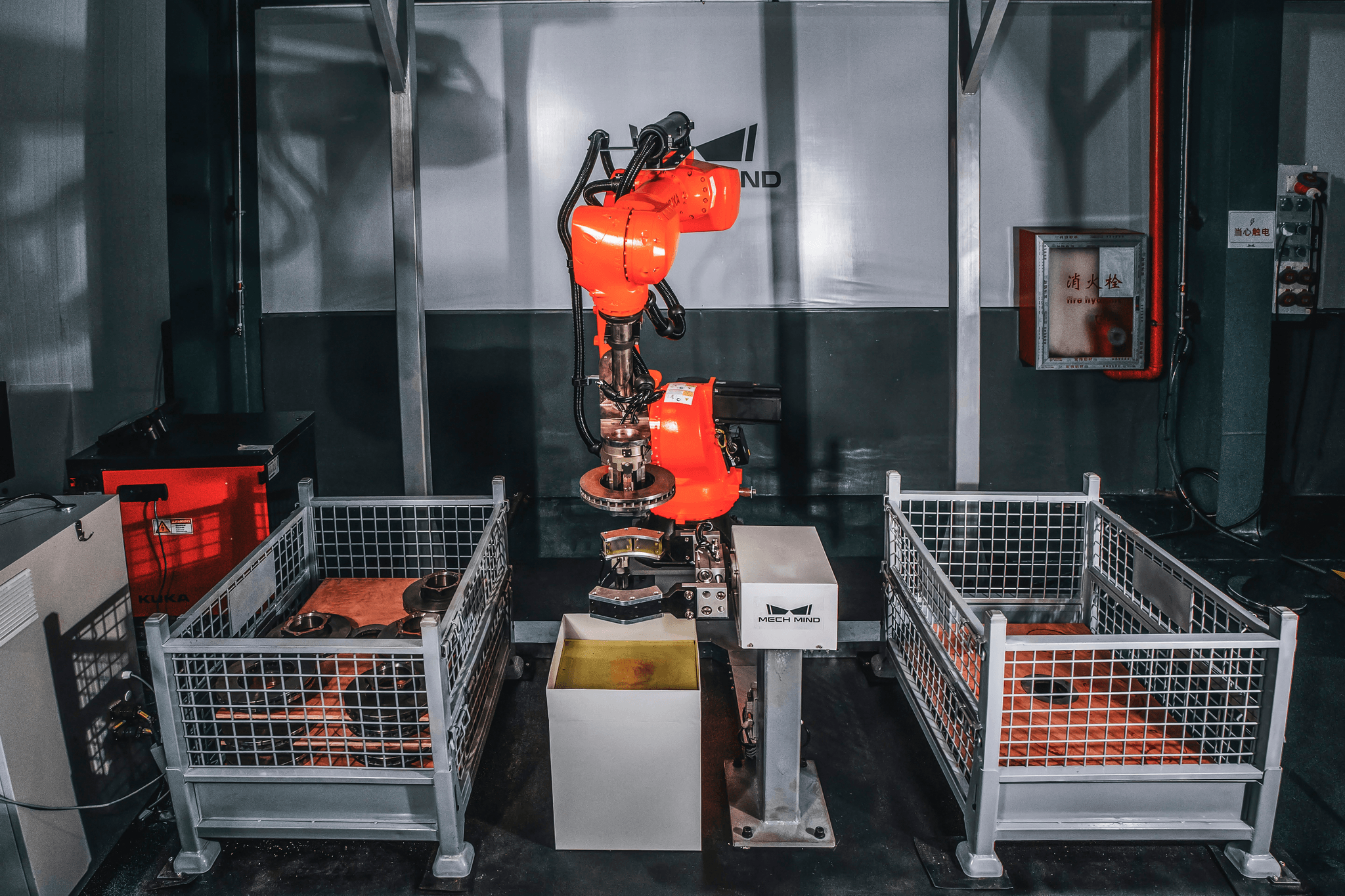

Robotics and Automation Enhancements

Robotics is another game-changer for prefab steel construction, streamlining processes that were once labor-intensive and time-consuming. Automated systems can handle repetitive tasks such as welding or assembly with unmatched precision, freeing up skilled workers to focus on more complex aspects of a project. PreFab Inc.'s investment in robotics ensures that every component meets stringent quality standards while minimizing human error.

Additionally, automation enhances safety on job sites by taking over hazardous tasks that could pose risks to workers. This not only protects employees but also accelerates project timelines by reducing delays caused by accidents or injuries. With robotics integrated into their operations, PreFab Inc. positions itself as a leader in efficient and safe prefab steel construction practices.

Smart Building Technologies

Smart building technologies are transforming how we interact with our constructed environments, particularly in the realm of prefab steel construction. These technologies allow for enhanced energy management systems that monitor consumption patterns and optimize resource use throughout a building's lifecycle. By incorporating smart features into their designs, PreFab Inc.’s projects not only improve sustainability but also elevate user experience through greater comfort and convenience.

Furthermore, smart buildings equipped with IoT devices can provide real-time data about structural health, enabling proactive maintenance before issues arise—an invaluable asset for property owners seeking longevity from their investments in prefab steel structures. This forward-thinking approach positions PreFab Inc.’s constructions as not just buildings but intelligent ecosystems designed for modern living and working environments.

In conclusion, advances in technology such as 3D printing, robotics automation enhancements, and smart building technologies are reshaping the landscape of prefab steel construction for companies like PreFab Inc., making it more efficient, safe, sustainable—and yes—exciting!

Sustainability in Prefab Steel Construction

In an era where environmental concerns are at the forefront of construction practices, prefab steel construction is leading the charge toward sustainability. This innovative approach not only enhances efficiency but also emphasizes eco-friendly materials and designs, making it a popular choice among environmentally conscious builders and developers. By integrating sustainable practices into their projects, companies like PreFab Inc. are setting new standards for the industry.

Eco-Friendly Materials and Designs

Prefab steel construction often utilizes recycled materials, significantly reducing the carbon footprint associated with traditional building methods. Steel itself is one of the most recyclable materials available, which means that structures can be designed with an eye toward future reuse or repurposing. PreFab Inc. takes pride in sourcing eco-friendly materials that not only meet stringent environmental standards but also offer durability and strength—key characteristics that define modern construction.

Moreover, innovative designs in prefab steel construction allow for more efficient use of space and resources, minimizing waste during both production and assembly phases. By prioritizing sustainable design principles, companies can create buildings that blend seamlessly into their environments while promoting energy conservation and reducing overall resource consumption. The focus on eco-friendly materials ensures that each project contributes positively to both the local community and the planet.

Energy Efficiency Innovations

Energy efficiency is a cornerstone of sustainability in prefab steel construction, with advancements in technology paving the way for smarter buildings. Innovative insulation techniques and energy-efficient systems help reduce heating and cooling costs while maintaining a comfortable indoor environment. PreFab Inc.'s commitment to integrating cutting-edge technologies ensures that their structures meet or exceed energy performance standards.

Additionally, smart building technologies enable real-time monitoring of energy usage, allowing occupants to optimize their consumption habits effectively. From automated lighting systems to advanced HVAC solutions, these innovations make it easier than ever for buildings to operate sustainably without sacrificing comfort or functionality. As a result, prefab steel construction stands out as a forward-thinking solution for those looking to minimize their environmental impact while enjoying modern conveniences.

Waste Reduction Strategies

One of the most significant advantages of prefab steel construction lies in its inherent ability to reduce waste throughout the building process. By fabricating components off-site under controlled conditions, manufacturers can minimize material waste compared to traditional on-site construction methods where excess scraps often end up in landfills. PreFab Inc.'s streamlined production process allows for precise measurements and cuts, ensuring optimal use of every piece of material.

Furthermore, implementing circular economy principles within prefab steel projects encourages recycling and repurposing at every stage—from design through demolition—further reducing waste generation over a structure's life cycle. This proactive approach not only conserves resources but also aligns with broader sustainability goals embraced by communities worldwide seeking greener development options. Ultimately, by prioritizing waste reduction strategies within prefab steel construction practices, companies like PreFab Inc., are helping pave the way toward a more sustainable future for all.

Design Flexibility and Customization

Prefab steel construction is revolutionizing the way we think about building design. With its inherent modularity, this approach allows for remarkable adaptability, enabling architects and builders to create structures that are not only functional but also visually striking. As we delve into the latest trends in modular design, collaborative platforms, and real-world examples, it becomes evident that prefab steel construction is paving the way for a new era of architectural creativity.

Modular Design Trends

The rise of modular design trends in prefab steel construction has transformed how spaces are conceived and executed. By breaking down buildings into manageable sections or modules, designers can easily adapt to varying site conditions and client needs while ensuring quality control during the manufacturing process. This flexibility not only speeds up construction times but also reduces waste—an essential factor in today’s environmentally conscious landscape.

Moreover, these modular designs can be tailored to suit different aesthetics or functional requirements without compromising structural integrity. From residential units to large commercial spaces, the versatility of prefab steel allows for innovative configurations that meet diverse architectural demands. PreFab Inc. embraces these trends by offering customizable solutions that cater to both traditional and avant-garde tastes.

Collaborative Design Platforms

In the realm of prefab steel construction, collaborative design platforms are game-changers that foster creativity and streamline communication among stakeholders. These digital tools enable architects, engineers, and clients to work together seamlessly throughout the design process—sharing ideas in real-time while visualizing changes instantaneously. Such collaboration ensures that everyone is on the same page from concept through execution.

These platforms often integrate advanced technologies like Building Information Modeling (BIM), which enhances accuracy in planning and reduces costly errors during construction. The result? A more efficient workflow that leads to higher-quality outcomes while maintaining budgetary constraints—a win-win situation for all involved! PreFab Inc.’s commitment to utilizing these innovative platforms underscores its dedication to pushing boundaries in prefab steel construction.

Real-World Examples of Custom Projects

The potential of prefab steel construction shines through when examining real-world projects that showcase its flexibility and customization capabilities. For instance, consider a recent housing development where each unit was designed with unique layouts tailored specifically for family needs while maintaining a cohesive aesthetic across the community. This level of personalization would be nearly impossible with traditional building methods but is easily achievable thanks to prefabrication techniques.

Another standout project involved an urban office complex where multiple businesses required distinct branding elements integrated into their spaces without sacrificing functionality or structural integrity—yet another triumph made possible through modular design principles! By leveraging these strategies effectively, PreFab Inc.’s portfolio continues to expand with inspiring examples demonstrating how customizable prefab steel solutions can transform visions into reality.

Cost Efficiency and Time Savings

In the ever-evolving world of construction, prefab steel construction has emerged as a game-changer, particularly in terms of cost efficiency and time savings. By utilizing advanced techniques and materials, projects can be completed faster and with fewer financial constraints. This not only benefits contractors but also clients who are eager to see their visions come to life without breaking the bank.

Streamlining the Construction Process

One of the most significant advantages of prefab steel construction is its ability to streamline the entire construction process. Traditional building methods often involve a myriad of delays due to weather conditions, material shortages, or labor inefficiencies. In contrast, with prefab steel, components are manufactured in controlled environments before being transported to the site for assembly, thus minimizing on-site disruptions and accelerating project timelines.

Moreover, this streamlined approach allows for better project management and coordination among teams involved. With precise planning and scheduling facilitated by PreFab Inc., construction timelines can be significantly reduced while maintaining high-quality standards. The result? Projects that are not only completed quicker but also come in under budget—an enticing prospect for any developer.

Reducing Labor Costs with Prefab Steel

Labor costs can often be one of the largest expenses in any construction project; however, prefab steel construction offers a compelling solution to mitigate these costs effectively. Assembling pre-manufactured components requires less on-site labor compared to traditional building methods that demand extensive manual work from skilled tradespeople. This reduction in labor needs translates into significant savings for contractors who choose PreFab Inc.’s innovative solutions.

Additionally, with fewer workers needed on-site at any given time, safety risks are minimized—leading to potentially lower insurance premiums as well! This combination of reduced labor requirements and enhanced safety protocols makes prefab steel an attractive option for businesses looking to optimize their budgets while still delivering quality projects on schedule.

Case Studies from PreFab Inc.

To illustrate the tangible benefits of prefab steel construction further, let’s take a look at some successful case studies from PreFab Inc., where cost efficiency was front and center. One notable project involved a large commercial facility that was completed 30% faster than projected due to our modular design approach—allowing clients to start operations sooner than expected.

Another case study highlighted how we helped a residential developer save 25% on labor costs by utilizing our prefabricated steel components instead of conventional materials. This not only allowed them to reinvest those savings into additional features but also ensured they met tight deadlines without compromising quality or safety standards.

Through these examples, it becomes clear that choosing prefab steel construction isn’t just about saving money; it’s about making smart decisions that lead to long-term benefits for all stakeholders involved.

The Future of Prefab Steel in Urban Development

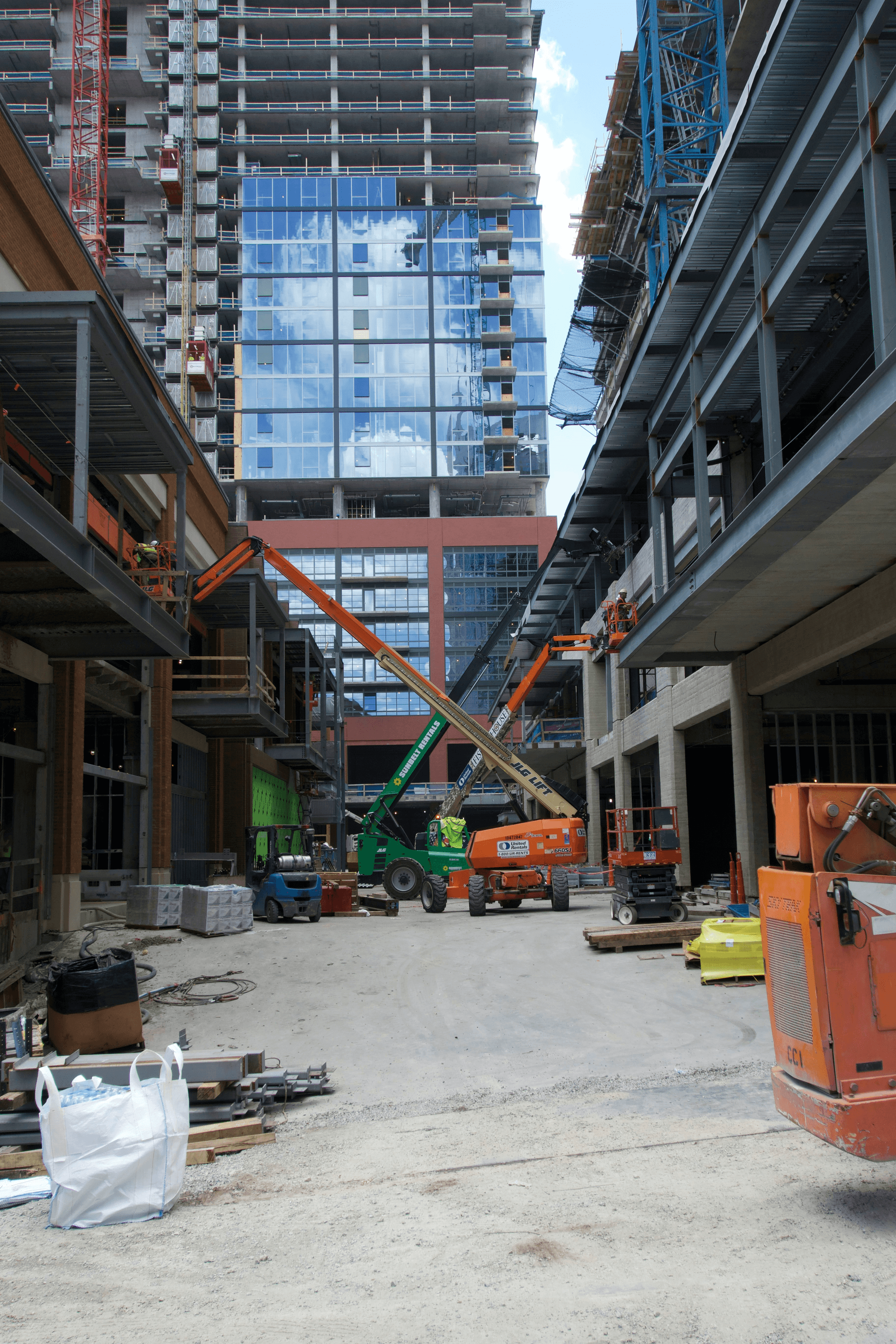

The landscape of urban development is rapidly evolving, and prefab steel construction is at the forefront of this transformation. As cities grow and populations swell, the demand for efficient, sustainable building solutions has never been higher. Prefab steel offers a streamlined approach that not only meets these demands but also enhances the aesthetic appeal of urban environments.

Urbanization and Demand for Prefab Solutions

Urbanization is driving an unprecedented need for innovative building methods, particularly in densely populated areas where space is limited. The rise of prefab steel construction addresses these challenges by providing quick, modular solutions that can be easily adapted to various site conditions. As cities expand upward rather than outward, prefab steel's versatility becomes a vital asset in meeting housing and commercial needs efficiently.

With more people flocking to urban centers for work and lifestyle opportunities, the pressure on infrastructure continues to mount. This increased demand for housing and commercial spaces highlights the necessity for rapid construction methods like prefab steel that minimize disruption while maximizing efficiency. By embracing these solutions, cities can better accommodate their growing populations without sacrificing quality or sustainability.

Innovative Projects Shaping Skylines

Across the globe, innovative projects utilizing prefab steel construction are redefining city skylines and setting new standards in architectural design. From sleek residential towers to expansive commercial complexes, these structures showcase how prefab techniques can blend functionality with striking aesthetics. Notable examples include mixed-use developments that integrate living spaces with retail options—all built using advanced prefabrication methods.

One standout project exemplifying this trend is a recent high-rise constructed entirely from prefab steel components, which not only reduced the overall build time but also minimized waste significantly during construction. These innovative designs are not just about looks; they prioritize energy efficiency and sustainability as core elements of urban development strategies moving forward. As more architects embrace prefab solutions, we will likely see even bolder designs emerge on city skylines worldwide.

The Role of PreFab Inc. in Future Developments

PreFab Inc., a leader in the prefab steel construction industry, is poised to play a pivotal role in shaping future urban developments across various landscapes. With cutting-edge technology and an unwavering commitment to quality, PreFab Inc.'s projects exemplify how modern building techniques can meet contemporary demands head-on while fostering sustainable practices within urban environments. Their expertise ensures that every structure not only meets zoning requirements but also enhances community engagement through thoughtful design.

As cities continue to evolve, PreFab Inc.’s focus on innovation will be crucial in addressing challenges like affordable housing shortages and environmental impacts associated with traditional construction methods. By leveraging advanced technologies such as 3D printing and smart building systems alongside their robust prefab offerings, they are setting benchmarks for efficiency and sustainability within the industry. Ultimately, PreFab Inc.'s contributions will help create vibrant urban spaces that reflect both modern needs and future aspirations.

Conclusion

The landscape of construction is evolving, and prefab steel construction is at the forefront of this transformation. With its innovative approaches and sustainable practices, the industry is embracing a future where efficiency and quality are paramount. As we look ahead, it’s clear that prefab steel will play a pivotal role in shaping modern architecture and urban development.

Embracing the Future of Construction

In an era where speed and efficiency are crucial, prefab steel construction offers solutions that traditional methods simply can't match. The integration of advanced technologies like 3D printing and robotics enhances not only productivity but also precision in building processes. By adopting these innovations, companies can ensure they remain competitive in a rapidly changing market.

The Competitive Edge of Prefab Steel

Prefab steel construction stands out due to its remarkable benefits: reduced waste, faster build times, and inherent design flexibility. This competitive edge allows builders to meet tight deadlines without compromising on quality or safety standards. As more stakeholders recognize these advantages, the demand for prefab solutions continues to surge across various sectors.

Why PreFab Inc. is Leading the Charge

PreFab Inc. has positioned itself as a trailblazer in the prefab steel construction industry by consistently delivering high-quality projects that meet modern demands. Our commitment to innovation and sustainability sets us apart from competitors while ensuring our clients receive exceptional value. With a focus on collaboration and customization, PreFab Inc. is well-equipped to lead the charge into the future of urban development.