Introduction

In recent years, the construction industry has witnessed a significant shift towards modular building installation, transforming the way structures are designed and erected. This innovative approach not only streamlines the construction process but also enhances efficiency and sustainability. As we delve into this exciting realm, it becomes clear why companies like PreFab Inc. are leading the charge in modular solutions.

The Rise of Modular Building Installation

Modular building installation has gained traction as a viable alternative to traditional construction methods, offering speed and flexibility that many projects demand today. With off-site fabrication and on-site assembly, these structures can be completed in a fraction of the time compared to conventional buildings. This rise is fueled by advancements in technology and a growing need for sustainable practices within the industry.

Benefits of Innovative Installation Techniques

The benefits of innovative installation techniques extend far beyond mere convenience; they encompass cost savings, reduced waste, and improved quality control. Modular building installation allows for precision manufacturing in controlled environments, minimizing errors that often occur on traditional job sites. Moreover, these techniques promote eco-friendly practices by optimizing resource use and reducing environmental impact—something PreFab Inc. prides itself on.

Why Choose PreFab Inc. for Your Modular Needs

When it comes to modular building installation, choosing the right partner is crucial for success—and that's where PreFab Inc. shines brightly in the industry landscape. Our commitment to quality craftsmanship combined with cutting-edge technologies ensures that your project meets both timelines and budget constraints without compromising on excellence. Trusting PreFab Inc. means opting for innovation that not only meets your needs but also aligns with sustainable goals.

Understanding Modular Building Installation

Modular building installation is revolutionizing the construction landscape, making it faster and more efficient to create functional spaces. This method involves constructing buildings off-site in a controlled environment before transporting them to the final location for assembly. It’s like building with Lego blocks but on a grander scale, where precision and innovation meet.

Basics of Modular Construction

At its core, modular construction is all about efficiency and speed. The process typically involves pre-fabricating sections or modules of a building in a factory setting, which allows for better quality control and reduced waste compared to traditional construction methods. Once these modules are completed, they are transported to the site, where they are assembled into a cohesive structure—often in just days rather than months.

This innovative approach not only accelerates the timeline but also minimizes disruptions at the installation site. With modular building installation, weather delays become a thing of the past since much of the work is done indoors. Plus, this method can be applied to various types of buildings—from residential homes to commercial spaces—making it incredibly versatile.

Key Components of Modular Buildings

Understanding the key components that make up modular buildings can shed light on why this approach is so effective. Typically, each module includes essential elements such as walls, floors, ceilings, electrical systems, plumbing fixtures, and even windows—all built to code before arriving at the site. These components are designed for easy transport and quick assembly while ensuring structural integrity.

PreFab Inc., for instance, emphasizes high-quality materials that enhance durability while keeping costs manageable during modular building installation projects. Each component works in harmony with others; think of it as an intricate puzzle where every piece fits perfectly together upon arrival at its destination. This meticulous planning ensures that when it’s time for installation, everything comes together seamlessly.

Advantages of Modular Installation Methods

The advantages of modular installation methods are numerous and compelling for both builders and clients alike. First off is speed; because many processes occur simultaneously rather than sequentially—like site preparation happening while modules are being built—projects can be completed significantly faster than traditional construction methods allow. This means quicker occupancy times and faster returns on investment.

Another significant benefit is cost-effectiveness; modular building installation often results in lower labor costs due to reduced onsite work hours and less material waste overall thanks to precise manufacturing techniques used by companies like PreFab Inc. Additionally, there’s an inherent flexibility within modular design that allows for easy expansion or reconfiguration down the line without extensive renovations.

Lastly—and perhaps most importantly—is sustainability; many modern modular installations prioritize eco-friendly practices by utilizing renewable materials and energy-efficient designs right from inception through completion. With PreFab Inc.’s commitment to sustainable practices in modular construction, clients can feel good knowing they’re making choices that benefit both their budget and our planet.

Cutting-Edge Technologies in Installation

In the ever-evolving landscape of modular building installation, technology plays a pivotal role in enhancing efficiency and precision. From advanced robotics to 3D printing and virtual reality, these innovations are revolutionizing how we approach construction. At PreFab Inc., we leverage these cutting-edge technologies to ensure that every project is not only innovative but also meets the highest standards of quality.

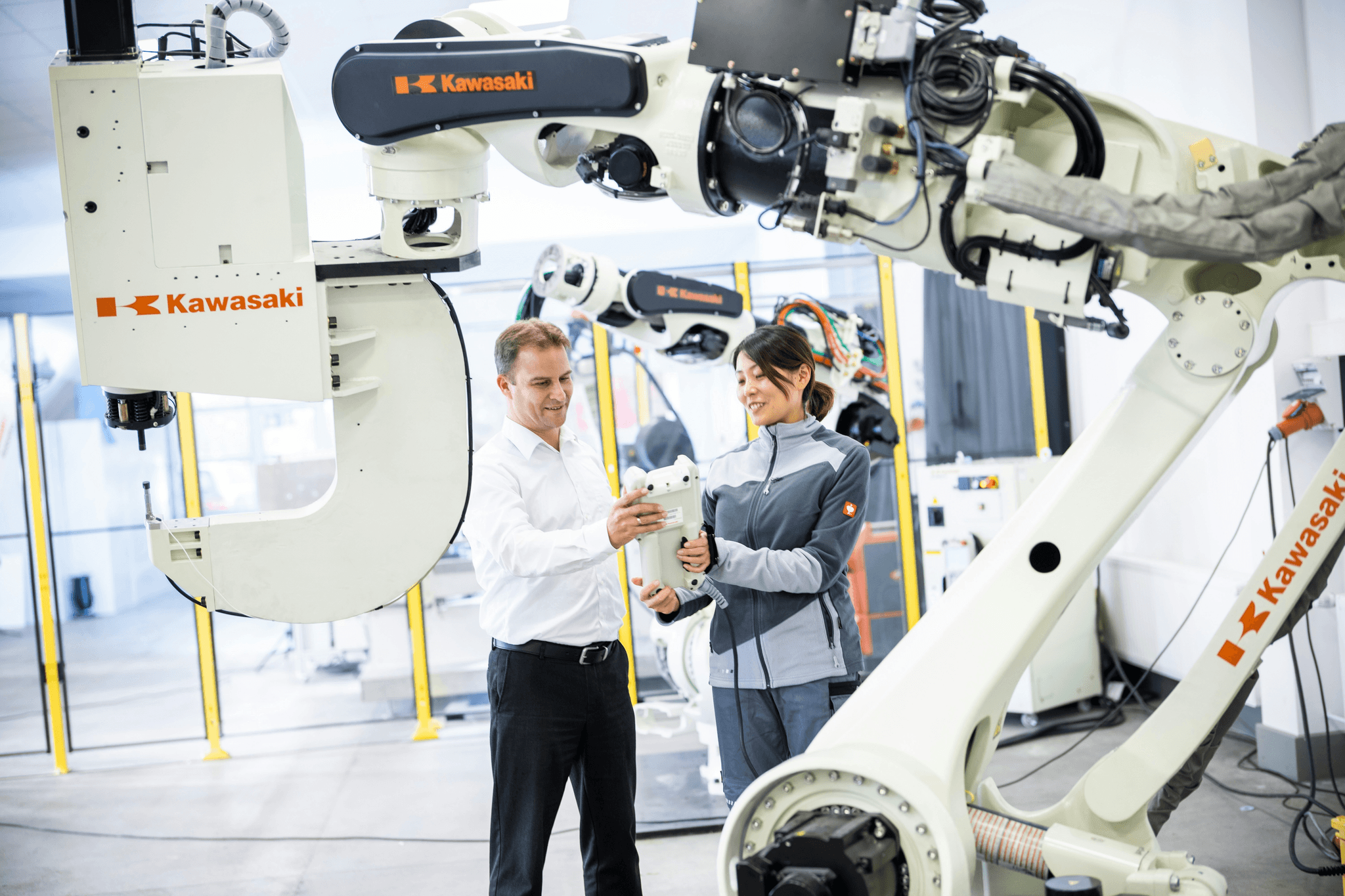

Advanced Robotics in Installation

Advanced robotics are transforming the modular building installation process by automating tasks that were once labor-intensive and time-consuming. These robots can handle repetitive tasks with remarkable precision, reducing human error and increasing overall productivity on-site. By integrating robotics into our installation processes at PreFab Inc., we can streamline workflows, allowing our teams to focus on more complex aspects of modular construction, ultimately delivering projects faster than ever before.

Moreover, robotic systems can work in environments that might be hazardous for human workers, ensuring safety while maintaining efficiency. The ability to deploy robots for tasks such as assembly or material handling means that modular building installation can be done with minimal disruption to surrounding areas. As technology continues to advance, PreFab Inc. remains committed to exploring new robotic applications that further enhance our modular solutions.

3D Printing and Its Impact

3D printing has emerged as a game-changer in the realm of modular building installation, enabling rapid prototyping and production of components with intricate designs. This technology allows us at PreFab Inc. to create customized parts tailored specifically for each project while reducing waste significantly compared to traditional methods. With 3D printing, we can produce complex geometries that enhance both functionality and aesthetic appeal in our modular buildings.

Additionally, the speed at which 3D-printed components can be produced means shorter lead times for projects, allowing us to meet tight deadlines without compromising quality. This capability is particularly beneficial for large-scale developments where time is often of the essence. As 3D printing technology continues to evolve, PreFab Inc. is excited about its potential applications across various aspects of modular construction.

Virtual Reality for Project Visualization

Virtual reality (VR) is another transformative tool shaping the future of modular building installation by providing immersive visualization experiences before construction even begins. With VR technology, clients can walk through their future spaces virtually—experiencing layouts and designs firsthand—allowing for real-time feedback and adjustments prior to actual build-out at PreFab Inc.. This level of engagement not only enhances client satisfaction but also ensures alignment between vision and execution.

Furthermore, VR aids our design teams by allowing them to visualize potential challenges during the planning phase rather than discovering them on-site when they could cause costly delays or modifications. By incorporating virtual reality into our design process, we enhance collaboration among stakeholders while streamlining decision-making processes associated with modular installations. As this technology matures, it holds great promise for further improving how we conceptualize and execute projects at PreFab Inc.

Sustainable Practices in Modular Construction

In recent years, sustainable practices have become a cornerstone of modular building installation, reflecting the industry's commitment to reducing environmental impact. By embracing eco-friendly materials and innovative methods, modular construction not only meets the demand for efficient housing solutions but also promotes a healthier planet. PreFab Inc. is at the forefront of this movement, ensuring that sustainability is woven into every aspect of their projects.

Eco-Friendly Materials and Methods

When it comes to modular building installation, eco-friendly materials are essential for minimizing carbon footprints. From recycled steel frames to sustainably sourced wood and low-VOC (volatile organic compounds) paints, PreFab Inc. prioritizes materials that are both durable and environmentally responsible. These choices not only enhance the longevity of structures but also contribute to healthier indoor air quality for occupants.

Moreover, innovative methods such as off-site fabrication significantly reduce waste generated during construction. By assembling components in controlled environments before transporting them to the site, PreFab Inc. ensures that excess materials are kept to a minimum while maximizing efficiency in modular building installation. This approach not only conserves resources but also speeds up project timelines—talk about a win-win!

Energy Efficiency in Modular Building Installation

Energy efficiency is another critical pillar of sustainable practices in modular construction. With advanced insulation techniques and energy-efficient systems integrated into each build, PreFab Inc.'s modular buildings are designed to operate with minimal energy consumption over their lifespan. This focus on energy efficiency translates into lower utility bills for homeowners while contributing positively to the environment by reducing greenhouse gas emissions.

Additionally, smart technologies like solar panels and energy management systems can be seamlessly integrated into modular installations, further enhancing their sustainability profile. These features ensure that homes remain comfortable year-round without compromising on ecological responsibility—a crucial consideration for modern buyers looking for sustainable living options.

The Role of PreFab Inc. in Sustainability

PreFab Inc.'s commitment to sustainability goes beyond just using eco-friendly materials; it extends into every facet of their operations and partnerships within the community as well. By collaborating with local suppliers who share similar values regarding environmental stewardship, they create a ripple effect that promotes sustainable practices across the industry landscape.

Furthermore, through ongoing research and development initiatives focused on improving green technologies in modular building installation, PreFab Inc. aims to lead by example and set new benchmarks for sustainability standards within construction sectors nationwide. As more people recognize the importance of eco-conscious living spaces, partnering with an innovative company like PreFab Inc.—which champions sustainable practices—becomes an obvious choice.

Case Studies of Successful Modular Installations

Modular building installation has taken the construction world by storm, and PreFab Inc. is at the forefront of this movement. By examining notable projects and innovations, we can gain insight into the transformative power of modular techniques in various environments. These case studies not only highlight our expertise but also illustrate the broader implications for urban housing solutions.

Notable Projects by PreFab Inc.

One standout project that showcases PreFab Inc.'s prowess in modular building installation is the Riverside Community Center, a vibrant hub designed to serve a diverse population. Completed in just six months, this center utilized prefabricated components that minimized on-site construction time while maximizing quality and functionality. The success of this project has set a new standard for community-focused modular installations.

Another remarkable venture was the Greenfield Apartments, where we integrated sustainable practices into our modular building installation process. Utilizing eco-friendly materials and energy-efficient systems, these apartments not only provide comfortable living spaces but also reduce environmental impact significantly. This project exemplifies how modular construction can meet modern demands while promoting sustainability.

Lastly, our partnership with local governments to create emergency housing solutions demonstrates PreFab Inc.'s adaptability in challenging scenarios. By rapidly deploying modular units for displaced families during crises, we have shown how efficient and effective modular building installation can be in addressing urgent needs while maintaining quality standards.

Innovations in Urban Modular Housing

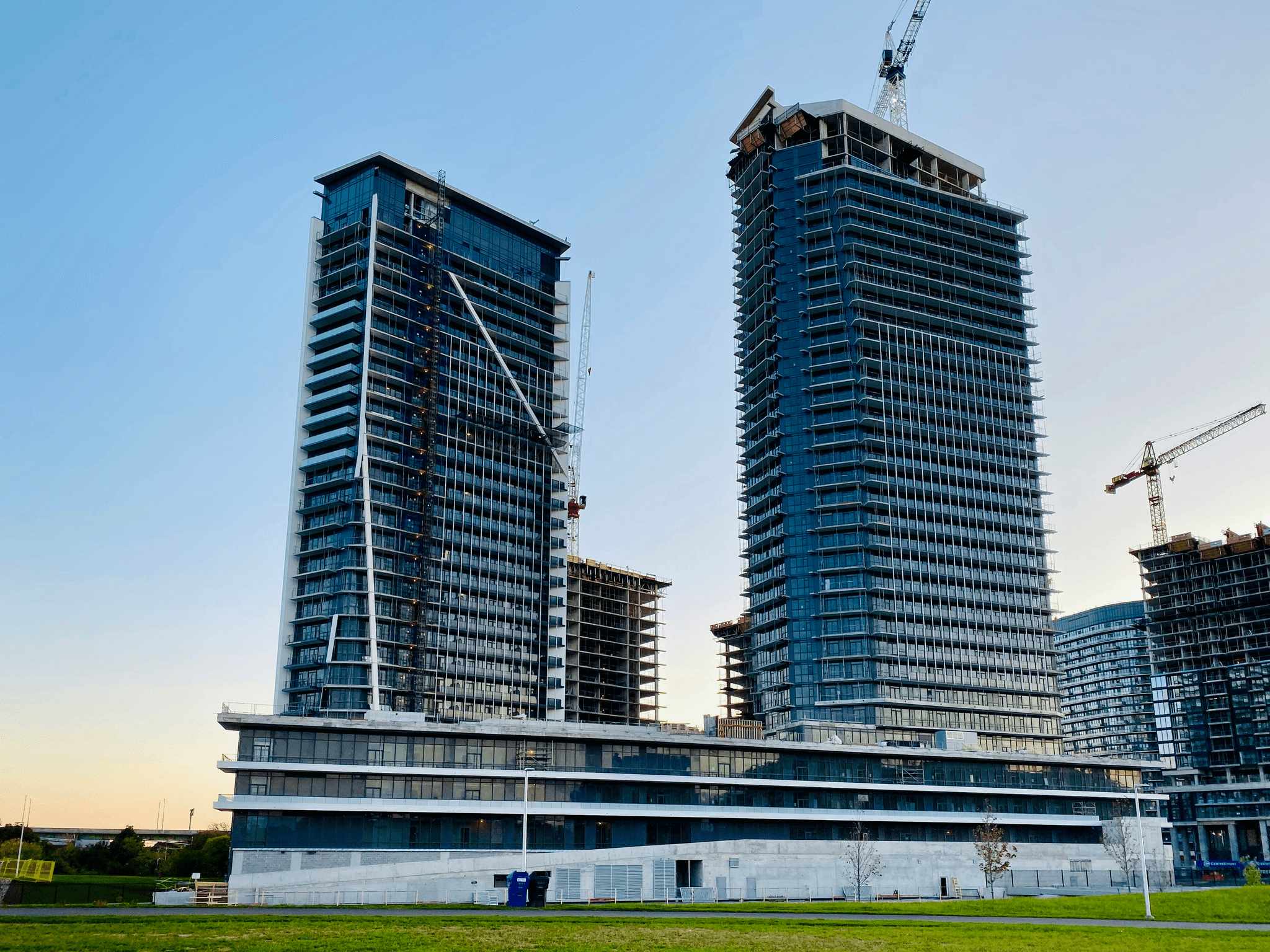

Urban areas face unique challenges such as space constraints and high costs; however, innovations in modular building installation are paving new paths forward. One exciting development involves using vertical stacking techniques to maximize limited land availability without sacrificing livability or aesthetics. Through creative designs and strategic planning, we’ve been able to transform underutilized spaces into thriving residential communities.

PreFab Inc.’s cutting-edge approach includes integrating smart technology within our urban modular housing projects. This allows residents to enjoy modern conveniences such as energy monitoring systems and automated climate control—all built right into their prefabricated homes! Such innovations enhance comfort while promoting sustainability through reduced energy consumption.

Moreover, collaborations with local artists have led to visually stunning urban installations that reflect community culture while adhering to efficient construction timelines. By incorporating artistic elements into our designs during the modular building installation phase, we've created not just homes but vibrant neighborhoods that foster community engagement and pride.

Lessons from Major Modular Installations

The journey through various successful projects has taught us invaluable lessons about overcoming challenges inherent in modular building installation processes. One key takeaway is the importance of thorough site assessments before commencing any project; understanding site limitations allows us to tailor our approach effectively from day one—saving time and resources down the line.

Additionally, navigating regulatory hurdles requires proactive communication with local authorities from inception through completion of each project—ensuring compliance without stalling progress on installations! Our experiences have reinforced that collaboration with stakeholders leads to smoother approvals and ultimately better outcomes for everyone involved.

Finally, engaging local communities early on fosters goodwill and support throughout each phase of a project’s lifecycle; listening to their needs ensures that what we build truly serves its intended purpose while enhancing overall satisfaction rates among residents post-installation! At PreFab Inc., these lessons continue shaping how we approach future endeavors within the realm of innovative modular construction solutions.

Challenges and Solutions in Modular Building

Modular building installation has its unique challenges, but with the right strategies, these hurdles can be effectively managed. Understanding the complexities of site limitations, regulatory requirements, and community relations is crucial for successful project execution. At PreFab Inc., we’re not just about building structures; we're about building solutions.

Overcoming Site Limitations

Site limitations can pose significant challenges to modular building installation, especially in urban environments where space is at a premium. Factors such as uneven terrain, restricted access points, or existing structures can complicate the installation process. However, innovative techniques like off-site assembly and advanced logistics planning allow PreFab Inc. to efficiently navigate these obstacles and deliver high-quality modular buildings on time.

To tackle site-specific issues effectively, we conduct thorough pre-installation assessments that help us anticipate potential problems before they arise. This proactive approach ensures that our teams are well-prepared to adapt to any unforeseen circumstances during the modular building installation process. By leveraging technology and expertise, we turn site limitations into opportunities for creative solutions.

Navigating Regulatory Hurdles

Regulatory hurdles can often feel like an intricate maze when it comes to modular building installation; however, understanding local codes and regulations is essential for smooth project execution. Different municipalities have varying rules regarding zoning, safety standards, and construction practices that must be adhered to meticulously. PreFab Inc.'s experienced team specializes in navigating these complexities by staying updated on local legislation and fostering relationships with regulatory bodies.

We believe that communication is key—engaging early with local authorities helps streamline approvals and permits necessary for modular installations. Additionally, our commitment to compliance not only ensures timely project completion but also builds trust within communities where we operate. Ultimately, by proactively addressing regulatory challenges, PreFab Inc. sets a standard for excellence in modular construction.

Collaborating with Local Communities

Successful modular building installation goes beyond just bricks and mortar; it involves engaging with local communities to create projects that meet their needs and aspirations. Community collaboration fosters goodwill and support while also providing valuable insights into what residents truly want from new developments. At PreFab Inc., we prioritize open dialogue with stakeholders throughout the entire process—from initial planning stages through final installation.

By hosting community meetings or workshops prior to breaking ground on a project, we gather feedback that informs our designs while addressing any concerns locals might have regarding changes in their environment due to new construction activities. This collaborative approach not only enhances community relations but also leads to more sustainable outcomes tailored specifically for those who will inhabit or utilize the spaces created through modular building installations.

In conclusion, overcoming challenges in modular construction requires innovative thinking combined with strategic partnerships—qualities that define PreFab Inc.'s commitment to excellence in every project.

Conclusion

In the rapidly evolving landscape of construction, modular building installation stands out as a game-changer. With its blend of efficiency, sustainability, and innovation, it offers a compelling alternative to traditional building methods. As we reflect on the insights shared throughout this discussion, it's clear that choosing modular construction is not just a trend; it's a smart investment for the future.

Key Takeaways on Modular Approaches

Modular building installation provides numerous benefits that cannot be overlooked. From reduced construction time to minimized waste and enhanced quality control, these approaches are transforming how we think about building. Moreover, with cutting-edge technologies and sustainable practices at their core, modular installations are paving the way for environmentally responsible development.

The Future of Building Installation

As we look ahead, the future of building installation appears bright with modular construction leading the charge. Innovations such as advanced robotics and 3D printing will continue to redefine what’s possible in terms of design and efficiency. With companies like PreFab Inc. at the forefront of this revolution, we can expect to see more upscale urban developments that meet modern demands while preserving our planet for future generations.

Trust PreFab Inc. for Your Next Project

When considering your next project, trust PreFab Inc. to deliver top-notch modular building installation solutions tailored to your needs. Our commitment to quality and sustainability ensures that your project will not only meet but exceed expectations while adhering to timelines and budgets. Join us in embracing the future of construction—where innovation meets reliability.