Introduction

In recent years, the construction industry has witnessed a remarkable transformation with the rise of prefabricated steel structures. These innovative building solutions are not only reshaping skylines but also redefining how we think about efficiency and sustainability in construction. With companies like PreFab Inc. leading the charge, the advent of prefabricated steel structure buildings is paving the way for a future where smart design and rapid deployment take center stage.

The Rise of Prefabricated Steel Structures

The popularity of prefabricated steel structures has surged due to their ability to dramatically reduce construction time and costs. By assembling components off-site, builders can streamline processes that traditionally slowed down projects, making it an attractive option for developers and contractors alike. This shift towards prefabrication marks a significant evolution in building practices, allowing for quicker responses to market demands while maintaining high-quality standards.

Benefits of Innovative Steel Designs

Innovative designs utilizing prefabricated steel structures offer numerous benefits beyond just speed and cost savings; they also promote sustainability through reduced waste and energy-efficient manufacturing processes. Additionally, these designs provide unparalleled flexibility, enabling architects to create customized spaces that meet specific needs without compromising structural integrity. As more stakeholders recognize these advantages, the adoption of innovative steel designs continues to gain momentum across various sectors.

Prefabulous: The Future of Construction

With advancements in technology and design methodologies, prefabulous is no longer just a catchy term; it's becoming synonymous with modern construction practices that embrace efficiency and creativity. The future of construction lies in leveraging prefabricated steel structure buildings that are not only functional but also aesthetically pleasing and environmentally responsible. As we look ahead, companies like PreFab Inc. are poised to lead this exciting evolution in how we build our environments—one steel beam at a time.

Transforming Construction with Prefabricated Steel

The construction industry is undergoing a remarkable transformation, largely thanks to the advent of prefabricated steel structures. These innovative designs are not just reshaping skylines but also redefining how we think about building efficiency, sustainability, and customization. With companies like PreFab Inc. leading the charge, the future of construction looks brighter and more adaptable than ever.

Efficiency and Speed in Building

When it comes to building projects, time is money—especially in today’s fast-paced world. Prefabricated steel structure buildings allow for rapid assembly on-site due to their pre-engineered components, which can be manufactured off-site simultaneously while site preparations are underway. This dual approach significantly reduces construction timelines and minimizes labor costs, making it an attractive option for developers looking to maximize their investment.

Moreover, the precision involved in creating prefabricated steel elements means fewer errors during assembly, allowing for quicker project turnover without sacrificing quality. With streamlined processes and reduced waste from excess materials or rework needed due to on-site errors, prefabricated steel structures offer unmatched efficiency that traditional building methods simply cannot match. Speedy completion doesn’t just benefit builders; it also means clients can start enjoying their new spaces sooner!

Sustainable Practices in Steel Manufacturing

Sustainability is no longer just a buzzword; it's an essential aspect of modern construction practices that the industry must embrace—especially when it comes to prefabricated steel structure buildings. The production of steel has evolved significantly over the years; today’s manufacturing processes prioritize recycling and energy efficiency as core principles. For instance, approximately 75% of all steel produced globally comes from recycled materials, drastically reducing the carbon footprint associated with new steel production.

PreFab Inc., committed to sustainability in its operations, utilizes advanced techniques that minimize waste throughout every phase—from design through fabrication to final assembly on-site. By focusing on sustainable practices such as energy-efficient manufacturing processes and responsible sourcing of raw materials, we not only create durable structures but also contribute positively to environmental conservation efforts. Choosing a prefabricated steel structure building isn't just smart; it's a conscious choice towards a greener future.

Customization and Flexibility in Designs

Gone are the days when buildings had to conform strictly to rigid designs! One of the standout features of prefabricated steel structure buildings is their incredible flexibility for customization—allowing architects and builders alike creative freedom without compromising structural integrity or safety standards. Whether you’re looking for unique shapes or specific functional requirements like open floor plans or multi-story configurations, these structures can be tailored precisely to meet your needs.

Additionally, advancements in technology mean that customization options are virtually limitless; from color choices to architectural styles and layouts tailored specifically for functionality or aesthetics—prefab designs can accommodate them all! At PreFab Inc., we pride ourselves on working closely with clients throughout this process so they can see their visions come alive while enjoying the benefits that come with using high-quality materials like steel—a perfect marriage between beauty and brawn.

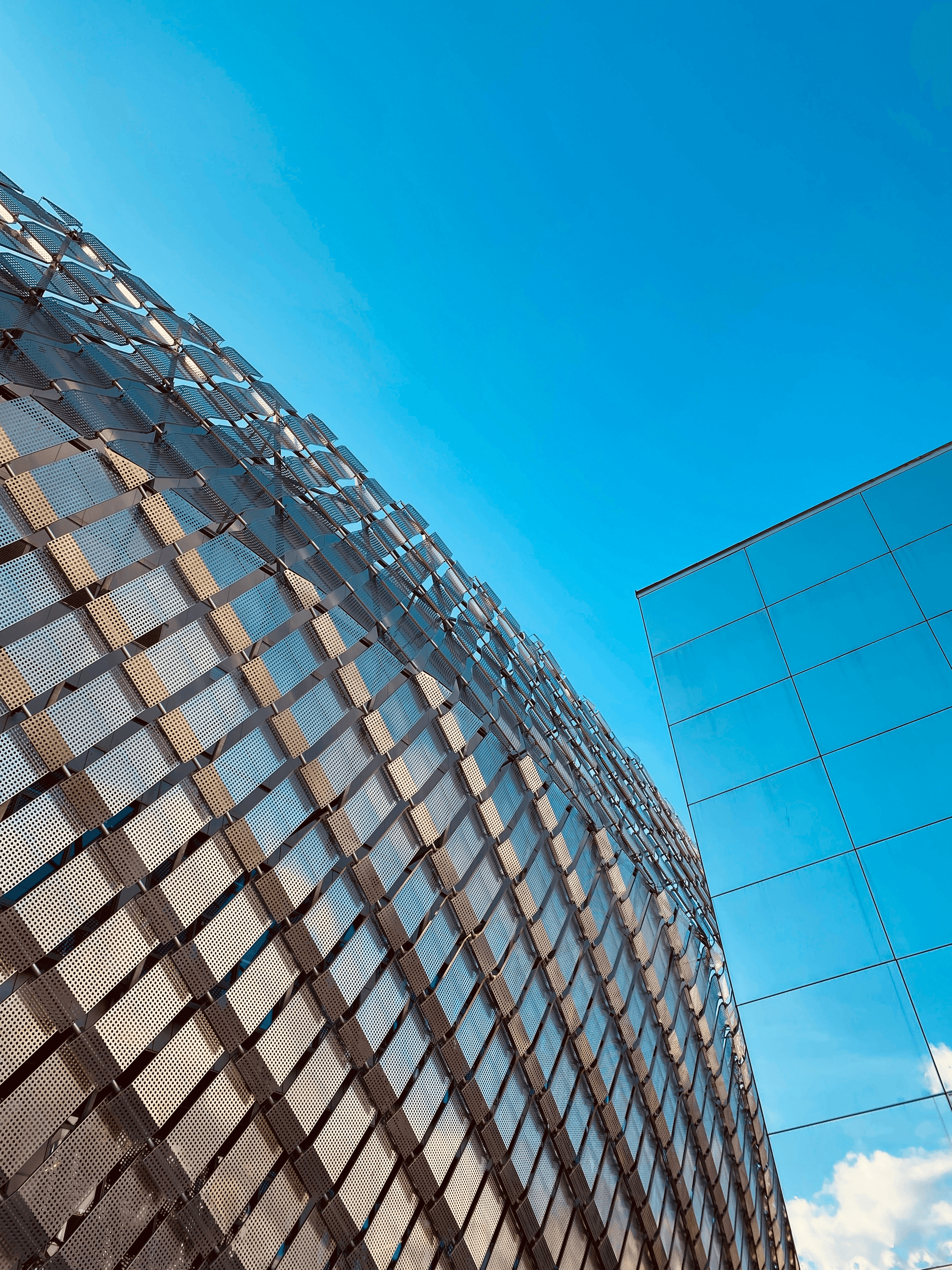

Iconic Prefabricated Steel Structures

In the realm of architecture, few things capture the imagination like iconic prefabricated steel structure buildings. These masterpieces not only showcase innovative design but also highlight the efficiency and versatility of prefabricated steel. Let's explore some remarkable examples that have redefined our understanding of what such structures can achieve.

The Louvre Museum's Glass Pyramid

The Louvre Museum's glass pyramid is a stunning example of a prefabricated steel structure building that seamlessly blends modernity with history. Designed by architect I.M. Pei, this iconic entrance to one of the world's most famous museums stands tall as a testament to innovative design principles and materials. The pyramid's sleek glass façade, supported by a robust steel framework, creates an inviting atmosphere while allowing natural light to flood the museum’s interior.

This prefabricated steel structure building not only enhances visitor experience but also symbolizes a bridge between past and present architectural styles. The use of glass and steel reflects contemporary aesthetics while paying homage to the historic surroundings of the Louvre Palace. PreFab Inc. admires such visionary projects that push boundaries and inspire future innovations in construction.

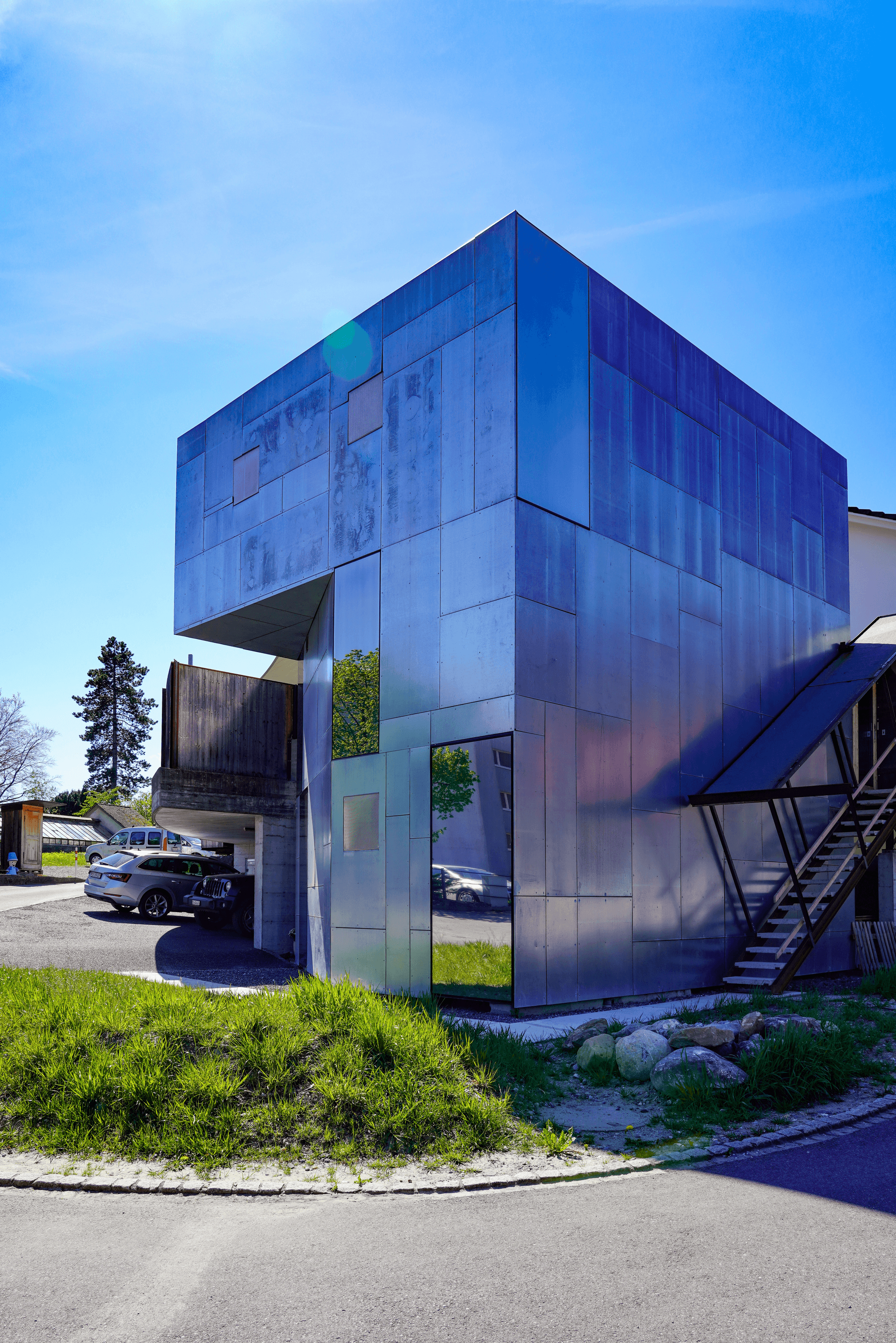

The Steel House by Robert Bruno

Nestled in Texas, The Steel House by architect Robert Bruno is another remarkable example showcasing the potential of prefabricated steel structure buildings. This unique residence is crafted entirely from weathering steel, giving it an organic yet modern appearance that harmonizes with its rugged landscape. Bruno’s artistic vision transformed traditional building methods into an expressive form where each curve and angle tells a story.

The house exemplifies how prefabricated elements can be both functional and aesthetically pleasing, defying conventional notions about residential architecture. Its open spaces and flowing lines demonstrate how custom designs can be achieved through innovative use of materials like prefabricated steel—truly an inspiration for future architects! At PreFab Inc., we appreciate such creativity that challenges norms while promoting sustainability in construction.

The Tsinghua University Gymnasium

The Tsinghua University Gymnasium stands as an architectural marvel in Beijing, showcasing how prefabricated steel structure buildings can cater to large-scale public needs while maintaining elegance in design. This facility features a striking undulating roof supported by intricate patterns of exposed steel trusses, providing both structural integrity and visual appeal for athletic events and gatherings alike. It’s a prime example where functionality meets artistry through advanced engineering techniques.

The gymnasium’s design emphasizes flexibility; it can accommodate various sporting events while offering spectators an immersive experience thanks to its open layout enhanced by natural lighting from large glass panels integrated into the design—a hallmark feature of modern prefabrication practices! Such projects highlight why PreFab Inc.'s commitment to innovation aligns perfectly with trends shaping contemporary architecture today.

Innovations in Design Technology

The landscape of construction is rapidly evolving, and at the forefront of this transformation is the integration of cutting-edge design technologies. Prefabricated steel structure buildings are increasingly benefiting from advancements that not only enhance efficiency but also redefine what’s possible in architectural design. Companies like PreFab Inc. are leading the charge, harnessing these innovations to deliver exceptional structures that meet modern demands.

3D Printing in Steel Construction

3D printing has emerged as a game-changer in the prefabricated steel structure building industry, allowing for unprecedented precision and creativity. This technology enables architects and engineers to create complex components that were previously impossible or prohibitively expensive to manufacture using traditional methods. With 3D printing, PreFab Inc. can produce bespoke steel elements tailored to specific project needs, ensuring that every building is as unique as its purpose.

Moreover, the use of 3D printing significantly reduces material waste—a key concern in sustainable construction practices today. By optimizing designs and minimizing excess material, prefabricated steel structure buildings become not only more environmentally friendly but also cost-effective for clients seeking innovative solutions without breaking the bank. As this technology continues to evolve, we can expect even more groundbreaking applications within the realm of prefabricated steel structures.

Smart Building Technologies

Smart building technologies are revolutionizing how we interact with our environments, particularly within prefabricated steel structure buildings. These technologies incorporate sensors and automation systems that monitor various aspects of a building's operation—from energy usage to security measures—creating a seamless user experience while enhancing efficiency. At PreFab Inc., we understand that integrating smart technology into our designs allows clients to enjoy modern conveniences while promoting sustainability.

Imagine controlling lighting, heating, and security from your smartphone! The potential for energy savings is immense; smart systems can adjust based on occupancy or time-of-day patterns, ensuring resources are used efficiently without sacrificing comfort or safety. As smart technologies continue to advance, they will play an essential role in shaping future prefabricated steel structures into intelligent living spaces.

BIM for Enhanced Planning and Execution

Building Information Modeling (BIM) has transformed project planning and execution within the construction industry by providing a digital representation of physical and functional characteristics of a project throughout its lifecycle. For companies like PreFab Inc., BIM enhances collaboration among architects, engineers, contractors, and clients by fostering real-time communication regarding design changes or updates during construction phases—essentially making everyone part of a cohesive team working towards a common goal.

With BIM's ability to simulate various scenarios before actual construction begins, stakeholders can identify potential issues early on—saving both time and money while ensuring structural integrity in prefabricated steel structure buildings remains uncompromised. Additionally, BIM facilitates better resource management by predicting material needs accurately based on detailed models rather than estimates alone; this leads directly back into reducing waste further down the line.

In conclusion, embracing these innovations allows PreFab Inc.'s projects not only to be built faster but also smarter—showcasing how technology can elevate traditional methods into something truly extraordinary.

Case Studies: Success Stories

In the realm of construction, few innovations have made as significant an impact as prefabricated steel structures. This section delves into notable case studies that highlight the successes and transformative potential of these modern marvels. From innovative projects by PreFab Inc. to their application in retail and emergency housing, the versatility of prefabricated steel is on full display.

PreFab Inc. Projects and Innovations

PreFab Inc. has been at the forefront of pioneering projects that showcase the strengths of prefabricated steel structure building. One standout project is their state-of-the-art modular office complex, which was completed in record time and under budget, demonstrating both efficiency and cost-effectiveness in construction practices. By utilizing advanced techniques and materials, PreFab Inc. has not only redefined what’s possible with prefabricated steel but also set new industry standards for quality and innovation.

Another remarkable achievement by PreFab Inc. is their collaboration with local governments to create prefabricated community centers designed for rapid deployment in urban areas. These structures exemplify how a prefabricated steel structure building can be both functional and aesthetically pleasing while addressing community needs swiftly during emergencies or expansions. Through these innovative projects, PreFab Inc. continues to prove that when it comes to modern construction, they are leading the charge.

The Success of a Steel Structure in Retail

The retail sector has also embraced the benefits of prefabricated steel structure buildings, with one notable example being a large-scale shopping center constructed entirely from this material by PreFab Inc. This project was completed ahead of schedule thanks to its modular design, allowing for quicker assembly without compromising on structural integrity or aesthetic appeal. The flexibility offered by prefabricated designs allowed retailers to customize spaces perfectly suited to their brands while maintaining an efficient workflow during construction.

Moreover, this shopping center has become a local landmark not just for its unique architecture but also for its sustainable features integrated into the design—showcasing how a prefabricated steel structure building can contribute positively to both commerce and community engagement alike. With energy-efficient systems embedded within its framework, this retail space exemplifies how modern design can harmonize with environmental responsibility—a win-win scenario!

Prefabricated Steel in Emergency Housing

In times of crisis where rapid response is crucial, prefabricated steel structure buildings have emerged as lifesavers—literally! One prominent initiative involved PreFab Inc.'s partnership with disaster relief organizations to provide emergency housing solutions after natural disasters struck various regions around the globe. These structures are designed for quick assembly yet strong enough to withstand harsh conditions while providing safe shelter for displaced individuals.

The adaptability of these homes means they can be customized based on specific needs—whether it’s accommodating families or creating communal living spaces—all while ensuring comfort through thoughtful design elements typical of traditional housing aesthetics despite being built from steel! This initiative not only highlights the resilience offered by prefab solutions but also emphasizes how investing in such technology can lead to more humane responses during emergencies.

Challenges and Solutions in Prefabricated Steel

While the benefits of prefabricated steel structure buildings are undeniable, several challenges remain that must be addressed for broader acceptance and implementation. Understanding these obstacles is key to unlocking the full potential of innovative steel designs. In this section, we will explore common misconceptions, the importance of structural integrity, and the complexities of regulatory compliance.

Addressing Perceptions and Misconceptions

One of the primary challenges facing prefabricated steel structure buildings is overcoming negative perceptions. Many people associate prefabrication with low-quality construction or temporary solutions, which couldn’t be further from the truth. PreFab Inc. aims to educate clients on how modern techniques can deliver durable, aesthetically pleasing structures that stand the test of time.

Moreover, there’s a misconception that prefabricated steel lacks customization options; however, advancements in design technology allow for endless possibilities in tailoring projects to meet specific needs. By showcasing successful projects and innovative designs, PreFab Inc. helps shift public perception towards viewing prefabricated structures as viable long-term solutions rather than mere stopgaps. As awareness grows about the quality and versatility of these buildings, more clients will embrace their advantages.

Ensuring Structural Integrity

Another critical challenge is ensuring structural integrity throughout the lifecycle of a prefabricated steel structure building. While steel is known for its strength and resilience, any flaws during manufacturing or installation can lead to significant issues down the line. PreFab Inc.’s commitment to rigorous quality control processes ensures that every component meets industry standards before it reaches construction sites.

Additionally, employing advanced engineering techniques during both design and assembly phases can mitigate risks associated with structural failures. By using high-quality materials along with precise fabrication methods, PreFab Inc. guarantees that each project not only meets but exceeds safety regulations—making sure your investment stands strong against time and nature alike! Ultimately, addressing concerns about structural integrity enhances trust in prefabricated solutions among builders and clients.

Navigating Regulatory Compliance

Navigating regulatory compliance remains one of the biggest hurdles for those involved in constructing prefabricated steel structure buildings. The complexity varies by location; different jurisdictions have various codes regarding safety standards, zoning laws, and environmental regulations that must be adhered to meticulously. PreFab Inc.’s experienced team stays updated on local building codes to ensure all projects comply seamlessly with legal requirements.

By collaborating closely with local authorities throughout each phase—from planning through execution—PreFab Inc. helps streamline approvals while minimizing delays caused by bureaucratic red tape or misunderstandings about regulations governing prefabrication practices! This proactive approach not only expedites timelines but also reinforces confidence among stakeholders regarding project viability within legal frameworks.

In conclusion, addressing perceptions around quality while ensuring structural integrity and navigating compliance challenges are vital steps toward popularizing prefabricated steel structures as a mainstream choice in construction today! With ongoing innovations from companies like PreFab Inc., we’re poised at an exciting intersection where creativity meets practicality in building design!

Conclusion

In conclusion, prefabricated steel structure buildings are not just a trend; they represent a transformative shift in how we approach construction. The environmental impact of these structures is significant, offering sustainable solutions that reduce waste and energy consumption. As we look to the future, the innovations in prefabrication will only enhance our ability to create efficient and adaptable buildings.

The Environmental Impact of Steel Buildings

Prefabricated steel structure buildings are known for their eco-friendly attributes, primarily due to their recyclability and energy efficiency. Steel can be recycled multiple times without losing its strength, making it an ideal choice for sustainable construction practices. Moreover, the manufacturing processes have evolved to minimize carbon footprints, ensuring that these structures contribute positively to the environment.

Future Trends in Prefabricated Steel Construction

Looking ahead, we can expect prefabricated steel structure buildings to incorporate even more advanced technologies such as smart systems and AI-driven design processes. These innovations will not only streamline construction but also enhance functionality and sustainability. With a growing emphasis on green building certifications and energy-efficient designs, PreFab Inc. is poised to lead the charge in this exciting evolution.

Why Choose PreFab Inc. for Your Next Project

When it comes to prefabricated steel structure buildings, PreFab Inc. stands out as a leader in innovation and quality. Our commitment to sustainability ensures that your project not only meets your needs but also aligns with environmental goals. Choosing us means investing in a future where efficiency meets elegance—because every building tells a story worth telling.