Introduction

In today's fast-paced construction landscape, the rise of prefabricated steel structures is transforming how buildings are designed and constructed. These innovative solutions offer a blend of efficiency, durability, and versatility that traditional construction methods often struggle to match. As we delve into this exciting trend, it becomes clear why companies like PreFab Inc. are at the forefront of this revolution.

The Rise of Prefabricated Steel Structures

Prefabricated steel structures have gained immense popularity in recent years due to their ability to streamline the building process. By fabricating components off-site and then assembling them on location, these structures significantly reduce construction time while maintaining high quality standards. PreFab Inc. has harnessed this trend, providing clients with cutting-edge solutions that meet modern demands for speed and reliability.

Benefits of Speedy Construction

One of the most compelling advantages of prefabricated steel structures is their ability to expedite construction timelines dramatically. With components pre-manufactured in controlled environments, projects can move from design to completion much faster than traditional methods allow. This rapid turnaround not only satisfies client expectations but also helps developers maximize their investment by reducing labor costs and minimizing disruptions.

Why Choose PreFab Inc.

When it comes to selecting a provider for your prefabricated steel structure needs, PreFab Inc. stands out as a leader in the industry. Our commitment to quality craftsmanship and innovative design ensures that every project meets or exceeds client specifications while adhering to stringent safety standards. By choosing PreFab Inc., you’re not just opting for a building; you’re investing in a future where efficiency meets excellence.

Understanding Prefabricated Steel Structures

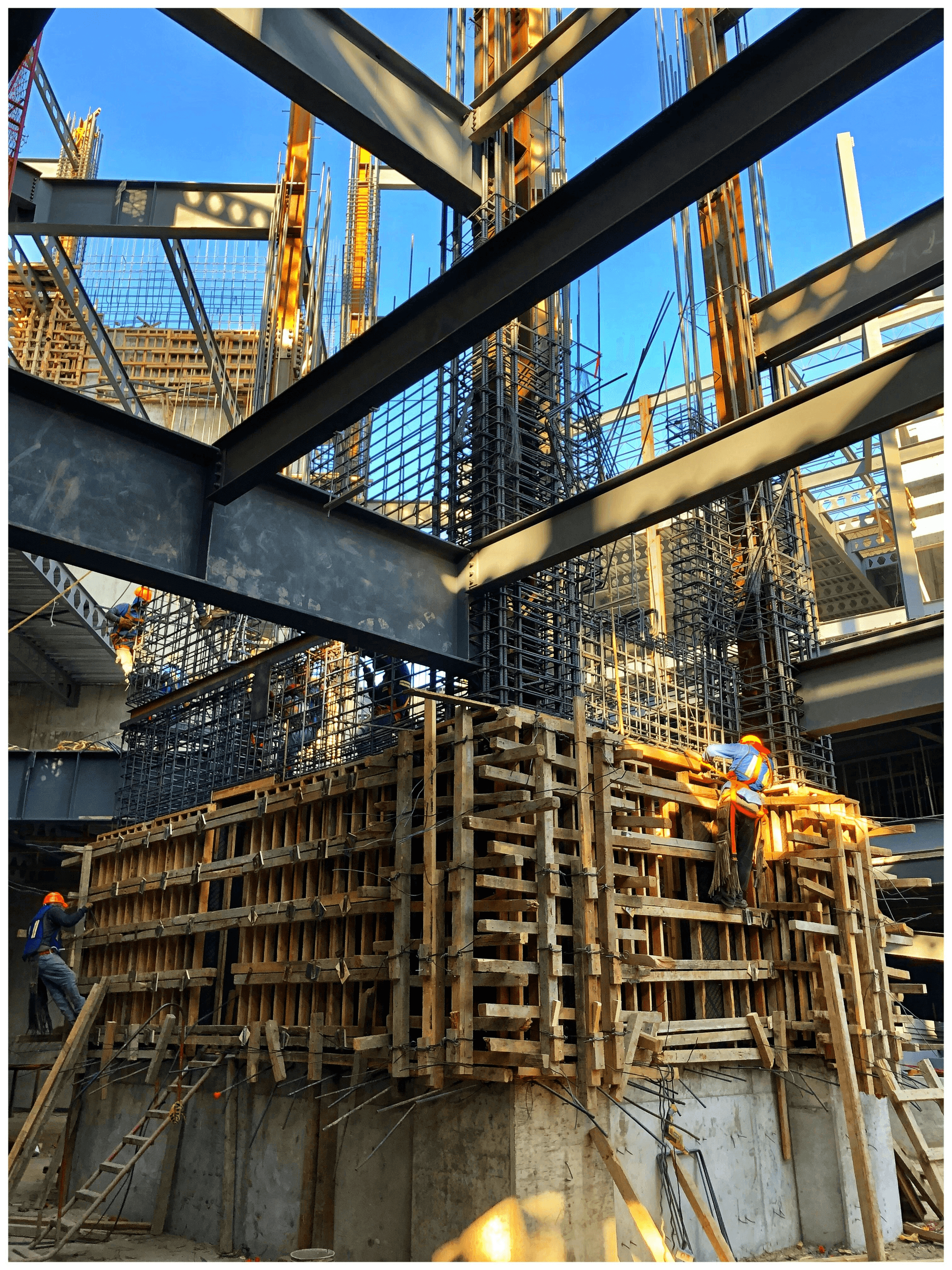

Prefabricated steel structures are revolutionizing the way we think about construction. These structures are built off-site in a controlled factory environment, allowing for precision and efficiency before being transported to the construction site for assembly. With components such as beams, columns, and panels manufactured to exact specifications, they represent a modern approach to building that combines innovation with practicality.

Definition and Components

At its core, a prefabricated steel structure is an assembly of steel parts that are fabricated in a factory setting and then shipped to the site for quick assembly. The main components typically include structural steel frames, roofing systems, insulation materials, and various finishing elements that can be tailored to specific needs. This method not only enhances durability but also ensures consistency in quality across all projects undertaken by companies like PreFab Inc.

Advantages Over Traditional Construction

One of the standout advantages of prefabricated steel structures is their remarkable speed of construction compared to traditional methods. With on-site work reduced significantly due to pre-manufactured components, projects can be completed in a fraction of the time it would take using conventional materials like wood or concrete. Additionally, prefabricated steel structures offer superior durability and resistance to environmental factors, making them a smart choice for developers looking for longevity.

Popular Applications in Modern Building

The versatility of prefabricated steel structures makes them suitable for various applications across multiple industries. From warehouses and industrial facilities to schools and hospitals, these structures are increasingly favored due to their adaptability and cost-effectiveness. Companies like PreFab Inc. have successfully delivered numerous projects that showcase the flexibility of prefabricated designs while meeting diverse client needs.

Streamlined Manufacturing Process

In the world of construction, the streamlined manufacturing process for prefabricated steel structures is revolutionizing how we build. PreFab Inc. has honed this process to maximize efficiency and minimize waste, ensuring that projects are completed on time and within budget. By moving much of the work off-site to a controlled factory environment, we can deliver high-quality steel components ready for rapid assembly.

Efficiency in Factory Settings

The efficiency found in factory settings is one of the standout features of prefabricated steel structures. At PreFab Inc., our state-of-the-art facilities allow us to manufacture components with precision and speed that traditional construction methods simply can't match. This controlled environment reduces delays caused by weather or site conditions, enabling us to keep projects on track.

Moreover, factory production enables simultaneous work on multiple components, further accelerating timelines without sacrificing quality. Each piece is crafted under optimal conditions, ensuring a consistent standard across all prefabricated steel structures produced. This level of efficiency translates directly into shorter lead times and quicker project completions.

Quality Control Measures

Quality control measures are paramount when it comes to prefabricated steel structures, and PreFab Inc. takes this responsibility seriously. Our rigorous inspection processes ensure that every component meets industry standards before it leaves the factory floor. By implementing systematic checks at various stages of production, we can catch any potential issues early on, reducing rework and enhancing overall quality.

Additionally, our skilled workforce is trained specifically in handling prefabricated materials, which contributes to superior craftsmanship in every project we undertake. This commitment to quality not only enhances safety but also elevates the longevity and performance of each structure built with our components. Clients can rest easy knowing that their investment in a prefabricated steel structure from PreFab Inc. is built to last.

Impact on Overall Construction Timeline

The impact of a streamlined manufacturing process on the overall construction timeline cannot be overstated when discussing prefabricated steel structures. With much of the building done off-site at PreFab Inc., on-site assembly becomes a matter of connecting pre-made pieces rather than starting from scratch with raw materials. This significantly reduces labor time required on site—allowing projects to move from groundbreaking to completion faster than ever before.

Furthermore, by shortening the construction timeline through efficient manufacturing and assembly techniques, developers benefit from quicker occupancy dates and faster returns on investment. The ability to predict project completion more accurately also aids in better planning for future projects or expansions within existing developments—an invaluable advantage in today's fast-paced market.

In summary, our streamlined manufacturing process at PreFab Inc., characterized by factory efficiency and stringent quality control measures, dramatically impacts construction timelines positively for all involved parties.

Rapid Assembly Techniques

When it comes to the construction of prefabricated steel structures, rapid assembly techniques are game-changers. These methods not only expedite the building process but also enhance overall project efficiency. By utilizing innovative strategies, PreFab Inc. ensures that your construction timeline is significantly reduced without compromising quality.

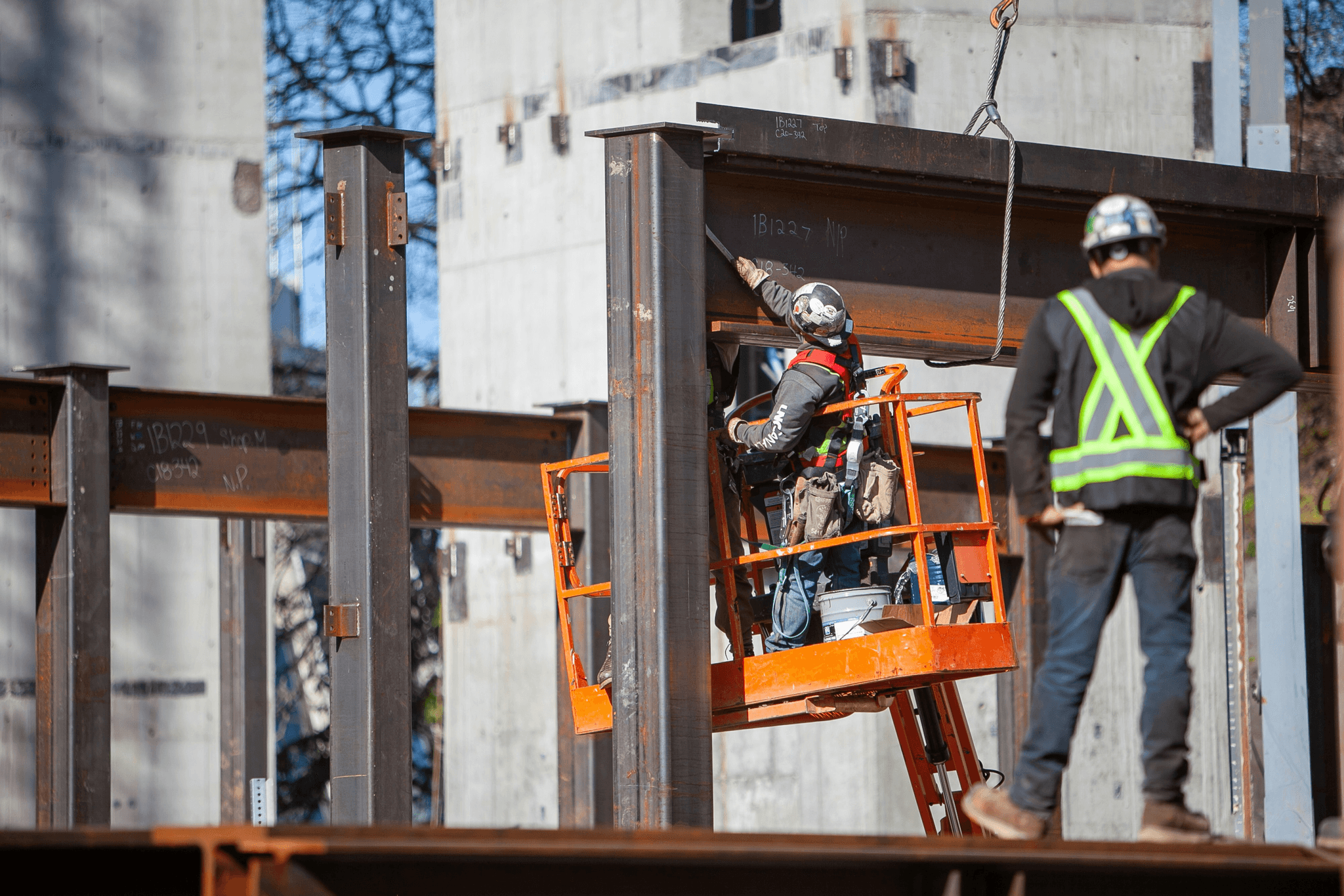

Pre-Assembly of Steel Components

Pre-assembly of steel components is a hallmark of our approach at PreFab Inc. By fabricating parts in a controlled factory environment, we can ensure precision and consistency in each piece of the prefabricated steel structure. This advanced technique allows for quicker on-site assembly, as components arrive ready to fit together seamlessly.

The pre-assembly process also minimizes the likelihood of errors that often occur during traditional construction methods, where adjustments are frequently needed on-site. With every component meticulously crafted and tested beforehand, builders can focus on erecting the structure rather than troubleshooting issues as they arise. Ultimately, this leads to a smoother workflow and faster completion times.

Reduced On-Site Labor Time

One of the standout benefits of using prefabricated steel structures is the significant reduction in on-site labor time. Because many elements are pre-fabricated off-site, there’s less need for extensive manpower at the construction site itself. This not only saves money but also minimizes disruptions in surrounding areas.

Moreover, with fewer workers required on-site, safety risks are greatly diminished—a win-win for everyone involved! The streamlined assembly process allows crews to focus their efforts more effectively and efficiently when they do arrive at the site. In essence, rapid assembly techniques translate into fewer headaches and greater productivity for all parties involved.

Example Projects from PreFab Inc.

At PreFab Inc., we pride ourselves on our successful implementation of rapid assembly techniques across various projects that showcase our expertise in prefabricated steel structures. One notable project involved a large commercial warehouse where we managed to reduce typical build time by 30%. Our use of pre-assembled components allowed us to complete this complex structure ahead of schedule while maintaining high standards.

Another example includes a multi-story office building where our innovative approaches led to significant savings in both time and labor costs for developers. These projects illustrate how effective our rapid assembly techniques can be when applied to real-world scenarios—transforming what could be lengthy builds into swift successes without sacrificing quality or safety standards.

Flexible Design Capabilities

Prefabricated steel structures are not just about speed and efficiency; they also offer remarkable flexibility in design. This adaptability allows architects and builders to create innovative solutions tailored to specific project requirements. At PreFab Inc., we pride ourselves on providing customizable options that meet the diverse needs of our clients.

Customization with Prefabricated Steel

One of the standout features of prefabricated steel structures is their high level of customization. With advanced manufacturing techniques, we can produce steel components that fit unique architectural designs, ensuring no two projects are alike. From bespoke sizes and shapes to specialized finishes, PreFab Inc. empowers clients to realize their vision without compromising on structural integrity.

Customization doesn’t just stop at aesthetics; it extends to functionality as well. Whether you need additional openings for windows or specific load-bearing capabilities, our prefabricated steel structures can be tailored accordingly. This level of personalization ensures that every project is not only visually appealing but also practical and efficient.

Adaptability for Various Projects

The versatility of prefabricated steel structures makes them suitable for a wide range of applications—from commercial buildings to residential homes and industrial facilities. No matter the project type, our designs can adapt seamlessly to any requirement, offering both strength and style in equal measure. At PreFab Inc., we understand that each project has its own unique challenges, and our team is equipped to tackle them head-on.

Additionally, the lightweight nature of prefabricated steel allows for easy modifications during construction without compromising stability or safety. This adaptability means projects can evolve over time, accommodating changes in design or function as needed—something traditional construction methods often struggle with. As a result, using prefabricated steel structures leads to enhanced longevity and sustainability for any building initiative.

Case Studies of Successful Projects

To showcase the incredible potential of prefabricated steel structures, let’s highlight a few successful projects completed by PreFab Inc. One notable example is a multi-story office complex designed with an eye-catching façade made entirely from customized steel panels—blending modern aesthetics with robust functionality seamlessly.

Another impressive project involved a large-scale warehouse facility where time constraints were critical; by utilizing our prefabricated solutions, construction was completed weeks ahead of schedule without sacrificing quality or safety standards. These case studies exemplify how flexible design capabilities can translate into real-world success stories while maximizing the benefits associated with prefabricated steel structures.

In summary, whether through customization or adaptability across various projects, PreFab Inc.'s commitment to innovation ensures that your vision can become reality with ease and efficiency.

Cost-Effectiveness and Time Savings

In today's fast-paced construction landscape, the cost-effectiveness of prefabricated steel structures has become a game changer. By streamlining various aspects of the building process, these innovative solutions not only save money but also deliver impressive value for developers. With PreFab Inc., you can expect a significant reduction in both upfront costs and long-term expenses associated with traditional building methods.

Budget Benefits of Prefabricated Structures

Prefabricated steel structures are designed with budget-conscious projects in mind, offering substantial savings from the outset. The controlled manufacturing environment allows for precision engineering and reduced waste, which translates to lower material costs compared to conventional construction methods. Additionally, because components are produced off-site, there’s less reliance on fluctuating labor rates that can drive up expenses unexpectedly.

Shortening Project Duration

One of the standout advantages of using prefabricated steel structures is the remarkable ability to shorten project timelines significantly. With components manufactured simultaneously while site preparation occurs, builders can begin assembly almost immediately upon delivery. This overlap not only accelerates completion but also allows developers to start generating revenue sooner than they would with traditional construction practices.

Long-Term Financial Advantages for Developers

Investing in prefabricated steel structures offers long-term financial benefits that extend well beyond initial savings. These structures often require less maintenance due to their durability and resilience against environmental factors, leading to reduced operational costs over time. Moreover, projects completed faster mean that developers can reinvest capital into new ventures sooner—an undeniable advantage in today’s competitive market driven by efficiency and speed.

Conclusion

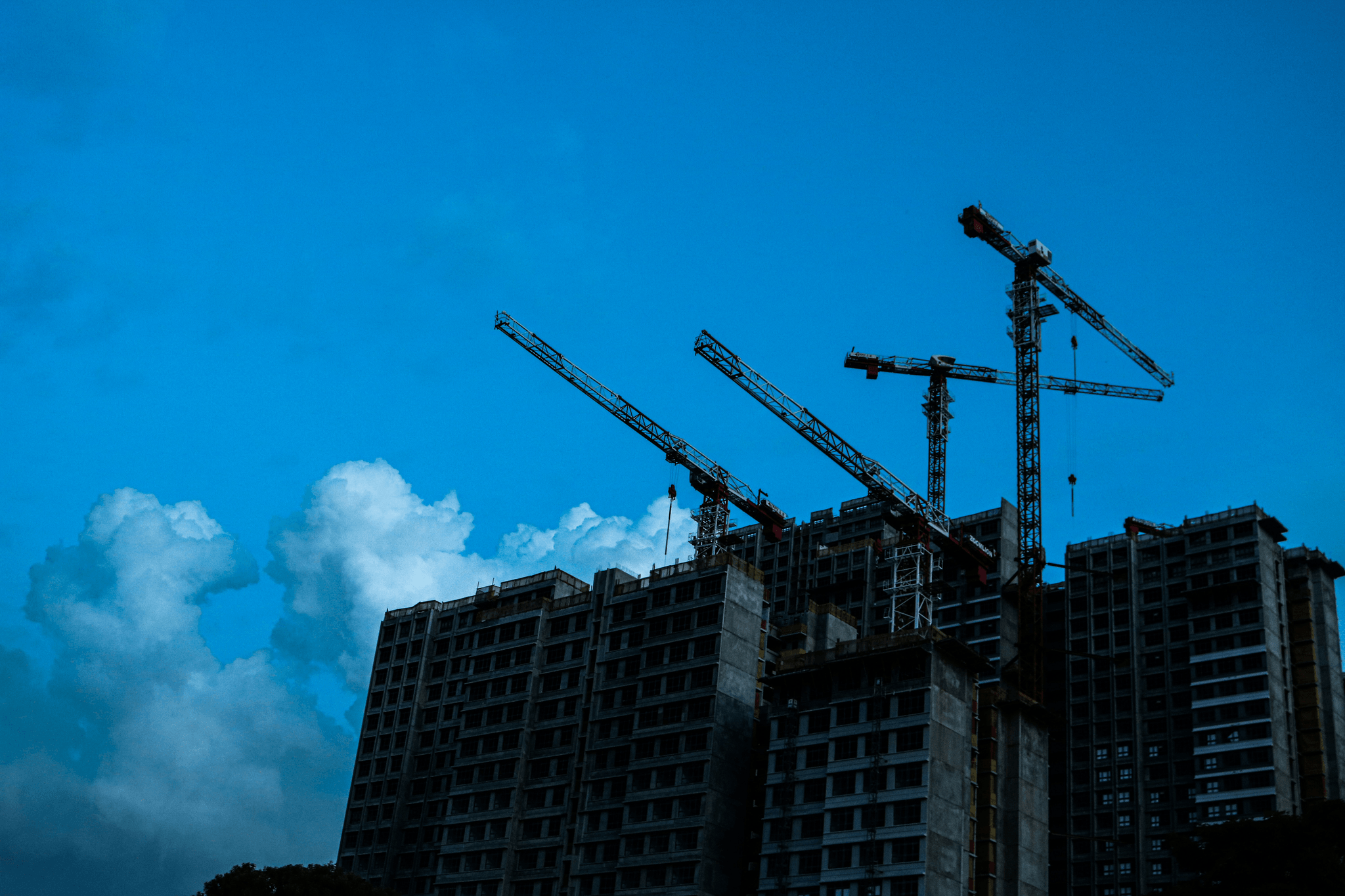

In a world where speed and efficiency are becoming paramount, the future of construction is undoubtedly leaning towards prefabricated steel structures. These innovative designs not only meet the demands of modern architecture but also promise sustainability and cost-effectiveness. As we look forward, it’s clear that prefabricated steel structures will play a pivotal role in shaping how we build.

The Future of Construction with Steel

The rise of prefabricated steel structures signifies a transformative shift in construction methodologies, paving the way for smarter building solutions. With their inherent strength and versatility, these structures are ideal for various applications, from residential homes to large commercial buildings. As technology advances, we can expect even more sophisticated designs that will optimize space and resources while reducing environmental impact.

How PreFab Inc. Leads the Way

At PreFab Inc., we pride ourselves on being at the forefront of this revolution in construction through our commitment to quality and innovation in prefabricated steel structures. Our streamlined processes ensure that each project is executed with precision, allowing clients to enjoy faster turnaround times without sacrificing quality or safety standards. By continually investing in cutting-edge technology and skilled craftsmanship, PreFab Inc. sets the benchmark for excellence in the industry.

Embracing Efficiency in Building Projects

Embracing prefabricated steel structures means embracing efficiency—both in time and cost savings for developers and builders alike. With reduced on-site labor requirements and quicker assembly techniques, projects can be completed significantly faster than traditional methods allow. As more companies recognize these advantages, partnering with leaders like PreFab Inc. will be essential for staying competitive in a rapidly evolving market.