Introduction

In recent years, the construction industry has witnessed a remarkable shift towards prefabricated steel construction, revolutionizing how structures are designed and built. This trend is not just a passing phase; it's a response to the growing demand for efficiency, sustainability, and innovative building solutions. As companies like PreFab Inc. lead the charge, the adoption of prefabricated steel components is becoming increasingly mainstream.

The Rise of Prefabricated Steel Construction

The rise of prefabricated steel construction can be attributed to its ability to streamline the building process while maintaining high standards of quality and durability. With advancements in technology and manufacturing techniques, steel components can now be fabricated off-site and assembled quickly on location, reducing labor costs and construction time significantly. This method not only enhances project timelines but also minimizes waste—a crucial factor in today’s eco-conscious world.

Benefits of Steel Construction Techniques

Steel construction techniques offer an array of benefits that make them an attractive option for modern builders. For starters, prefabricated steel structures are incredibly strong yet lightweight, allowing for more flexible designs without compromising safety or stability. Additionally, these techniques promote sustainable practices by enabling easier recycling and reuse of materials at the end of their lifecycle—an essential consideration as we strive for greener building solutions.

Innovations Transforming the Industry

Innovations in technology are continuously transforming the landscape of prefabricated steel construction, paving the way for smarter design and execution processes. From Building Information Modeling (BIM) that enhances project visualization to advanced fabrication methods that improve precision, these innovations are setting new standards in efficiency and quality control. Companies like PreFab Inc. are at the forefront of this transformation, harnessing cutting-edge technologies to push boundaries in steel construction.

Prefabricated Steel Components

Prefabricated steel construction is revolutionizing the way we build, offering efficiency and versatility that traditional methods struggle to match. By utilizing advanced fabrication techniques, components are manufactured off-site and then assembled on location, significantly reducing construction time. This section dives into the intricacies of the steel fabrication process, key industry players, and a spotlight on PreFab Inc.'s innovative modular solutions.

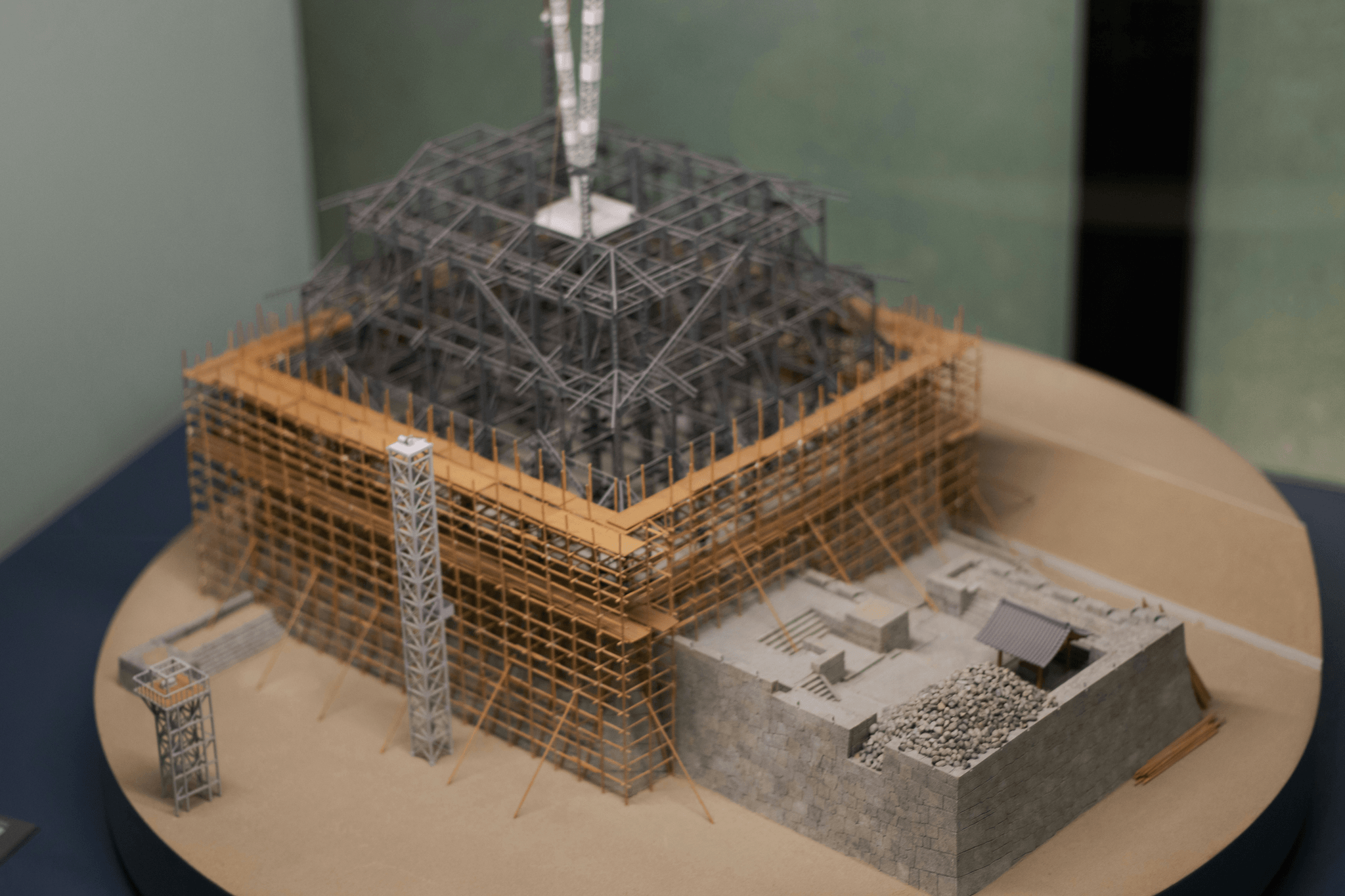

Overview of Steel Fabrication Process

The steel fabrication process is a symphony of precision engineering and advanced technology. It begins with the design phase, where architects and engineers collaborate to create detailed blueprints for prefabricated steel components. These designs are then translated into reality through cutting-edge machinery that shapes raw steel into beams, columns, and other structural elements essential for prefabricated steel construction.

Once fabricated, these components undergo rigorous quality control checks to ensure they meet safety standards and specifications. After passing inspections, they are transported to the construction site for quick assembly—a stark contrast to traditional building methods that often lead to delays due to on-site adjustments. With this streamlined approach, projects utilizing prefabricated steel can see completion in record time while maintaining high-quality standards.

Major Players in Prefabrication

In the realm of prefabricated steel construction, several major players have emerged as leaders in innovation and production efficiency. Companies like PreFab Inc., Steel Dynamics Inc., and Nucor Corporation are at the forefront of this industry transformation, each contributing unique strengths from advanced manufacturing techniques to sustainable practices in their operations. Their combined efforts not only push technological boundaries but also set benchmarks for quality in prefabrication.

These companies invest heavily in research and development to enhance their fabrication processes continually; from automated welding systems to robotics that streamline assembly lines—innovation is at their core. Moreover, partnerships with tech firms allow them to integrate software solutions like BIM (Building Information Modeling) into their workflows—an essential element for modern prefabricated steel construction projects aiming for precision and efficiency.

Case Study: PreFab Inc.'s Modular Solutions

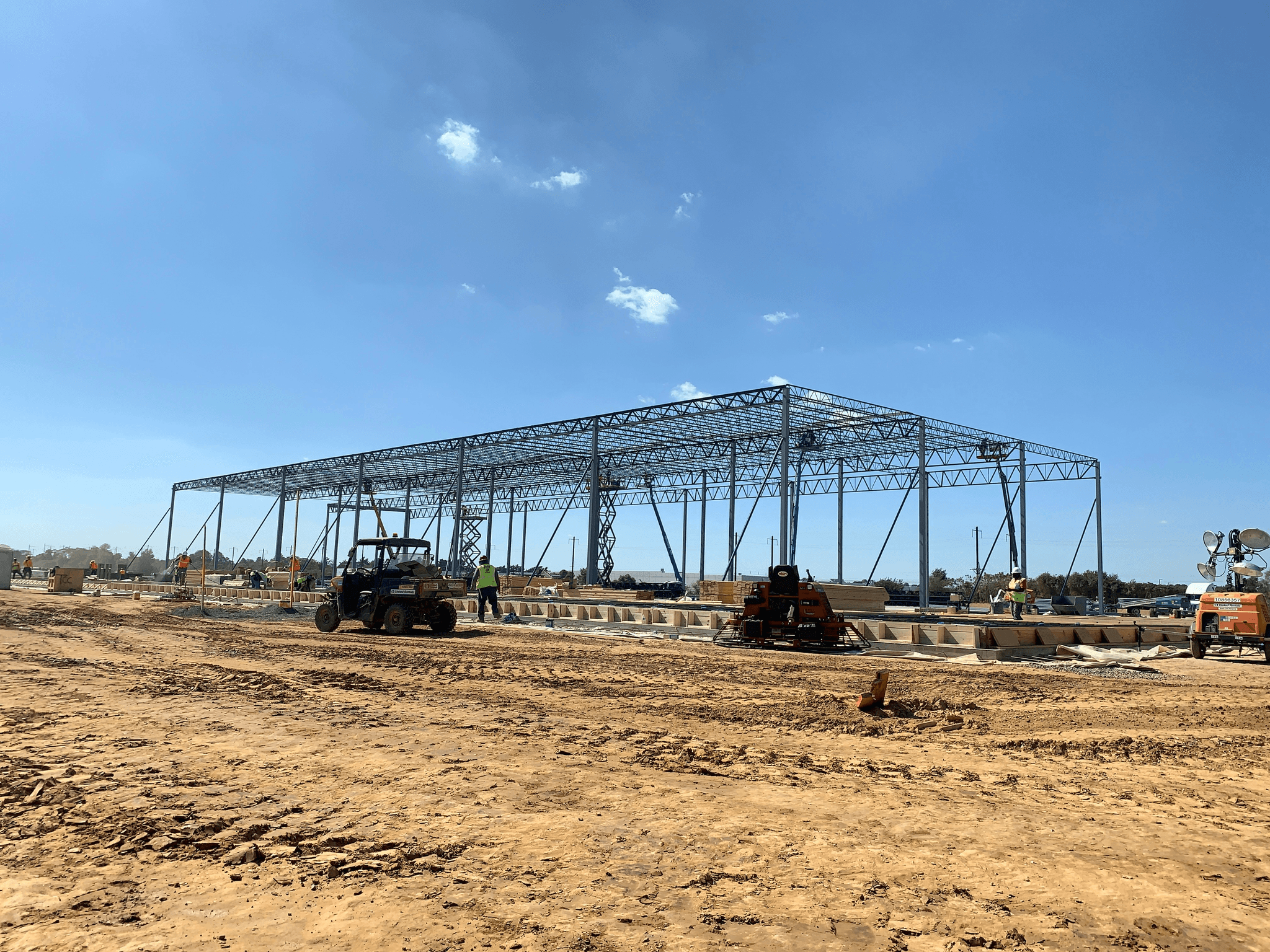

PreFab Inc.'s modular solutions exemplify how prefabricated steel construction can redefine building methodologies across various sectors—from residential homes to commercial spaces. By employing an innovative approach that focuses on modularity, PreFab Inc. crafts entire sections of buildings off-site before transporting them ready for quick assembly on location—think giant Lego blocks but made from sturdy steel! This not only accelerates project timelines but also minimizes waste during construction.

One standout project by PreFab Inc. involved constructing a multi-story office building entirely from prefabricated steel modules within just a few months—a feat that would typically take over a year using conventional methods! The success of this project showcases how strategic planning alongside cutting-edge technology can yield impressive results while adhering strictly to sustainability practices often associated with modern architecture today.

Sustainable Practices in Steel Construction

Sustainability is no longer just a buzzword; it’s a crucial aspect of modern construction, especially in prefabricated steel construction. As the industry evolves, companies like PreFab Inc. are leading the charge towards greener practices that not only benefit the environment but also enhance project efficiency and appeal. By integrating sustainable methods into their operations, they are setting new standards for what it means to build responsibly.

Recycling in Steel Production

One of the most significant advantages of prefabricated steel construction is its inherent recyclability. Steel can be recycled repeatedly without losing its structural integrity, making it one of the most sustainable building materials available today. PreFab Inc. takes pride in sourcing recycled steel for their projects, significantly reducing waste and energy consumption associated with new steel production.

The recycling process for steel involves melting down scrap metal and reforming it into new products, which requires less energy than producing virgin steel from raw materials. This not only conserves natural resources but also reduces greenhouse gas emissions associated with mining and processing iron ore. By choosing prefabricated steel construction, builders can contribute to a circular economy where materials are reused efficiently.

Moreover, incorporating recycled materials into construction projects can help meet various sustainability goals and certifications, further enhancing the appeal of prefabricated solutions offered by companies like PreFab Inc. The commitment to recycling within the industry underscores a broader trend toward responsible manufacturing practices that prioritize environmental stewardship.

Energy Efficiency Innovations

Energy efficiency is another cornerstone of sustainable practices in prefabricated steel construction. Advances in technology have led to innovative designs that minimize energy consumption during both construction and operation phases of buildings. For instance, PreFab Inc.'s modular solutions often feature insulation systems that significantly reduce heating and cooling demands over time.

Additionally, incorporating renewable energy systems such as solar panels or wind turbines into prefabricated structures enhances their sustainability profile even further. These technologies allow buildings to generate their own energy while reducing reliance on fossil fuels—an essential step toward combating climate change through smarter design choices within the realm of steel construction.

Furthermore, energy-efficient designs not only lower operational costs for building owners but also create healthier living environments for occupants by improving indoor air quality and overall comfort levels—an attractive proposition for modern developers looking to invest in long-term value through sustainable practices.

Green Building Certifications

In today's competitive market, achieving green building certifications has become a vital consideration for any company involved in construction—including those specializing in prefabricated steel construction like PreFab Inc. These certifications provide an independent verification of a project’s environmental performance based on established criteria such as energy efficiency, water conservation, and material sustainability.

Certifications such as LEED (Leadership in Energy and Environmental Design) or BREEAM (Building Research Establishment Environmental Assessment Method) recognize efforts made towards creating eco-friendly buildings while promoting best practices across various sectors within the industry. By aligning with these standards through innovative design approaches using prefab techniques, companies can attract environmentally conscious clients who prioritize sustainability alongside aesthetics.

Moreover, obtaining green certifications not only enhances marketability but also opens doors for potential funding opportunities or tax incentives aimed at supporting environmentally friendly initiatives—making them an appealing goal for businesses committed to advancing sustainable practices within prefabricated steel construction.

Advances in Technology and Design

The landscape of prefabricated steel construction is evolving rapidly, driven by technological advancements that enhance efficiency and design capabilities. Innovations such as Building Information Modeling (BIM) and 3D printing are reshaping how we approach construction projects, allowing companies like PreFab Inc. to push the boundaries of what’s possible in the industry. As we explore these advances, it becomes clear that technology not only streamlines processes but also fosters creativity in design.

The Role of BIM in Prefabrication

Building Information Modeling (BIM) has revolutionized prefabricated steel construction by providing a digital framework for planning and executing projects. This technology enables stakeholders to visualize the entire project before breaking ground, minimizing errors and enhancing collaboration among architects, engineers, and contractors. At PreFab Inc., BIM is utilized to create detailed models that facilitate precise fabrication of steel components, ensuring that everything fits together seamlessly on-site.

Moreover, BIM allows for real-time updates and changes during the construction process, making it easier to adapt to unforeseen challenges without significant delays or cost overruns. By integrating various elements of a project into a single model, prefabricated steel construction becomes more efficient and less prone to miscommunication or oversight. Ultimately, leveraging BIM not only accelerates timelines but also elevates the quality of finished structures.

3D Printing and Steel Construction

3D printing is another groundbreaking technology making waves in the realm of prefabricated steel construction. This method allows for rapid prototyping and production of complex steel components that traditional fabrication methods may struggle with. Companies like PreFab Inc. are exploring how 3D printing can reduce material waste while enabling intricate designs that enhance both aesthetics and functionality.

The ability to produce custom parts on demand means that projects can be more flexible than ever before; if changes are needed mid-construction, adjustments can be made swiftly without impacting overall schedules significantly. Additionally, 3D printing supports sustainability initiatives by utilizing recycled materials in production processes—an essential consideration in today’s eco-conscious building environment. As this technology matures, its integration into prefabricated steel construction will likely become standard practice.

Technology Leaders: Autodesk and Tekla

When discussing advances in prefabricated steel construction technologies, two names stand out: Autodesk and Tekla. Both companies offer cutting-edge software solutions designed specifically for enhancing workflows within the construction industry—especially regarding BIM applications and structural analysis tools tailored for steel fabrication projects like those at PreFab Inc.. Their platforms empower designers with advanced modeling capabilities while improving coordination among project teams.

Autodesk's suite includes tools such as Revit which integrates seamlessly with other software applications used throughout the lifecycle of a building project—from initial design through final inspection—ensuring every detail is accounted for along the way. Meanwhile, Tekla focuses heavily on structural engineering aspects; their solutions provide robust functionalities for managing complex assemblies typical in prefabricated steel construction scenarios where precision is paramount.

In summary, embracing these technological innovations not only streamlines processes but also enhances design possibilities within the realm of prefabricated steel construction—a win-win situation all around!

Case Studies of Successful Steel Projects

Prefabricated steel construction has made waves in the architectural world, showcasing its ability to create stunning and functional structures. From towering skyscrapers to expansive bridges, steel has become synonymous with durability and innovation. In this section, we’ll explore some iconic structures built with steel, draw lessons from successful prefabricated projects, and analyze the broader impact of steel construction on the industry.

Iconic Structures Built with Steel

When you think of iconic architecture, it’s hard to overlook the Eiffel Tower or the Sydney Opera House—both masterpieces that utilize steel in their design. These structures not only represent engineering marvels but also highlight how prefabricated steel construction can be both aesthetic and functional. The Burj Khalifa, currently the tallest building in the world, is another prime example; its impressive height is made possible by advanced steel fabrication techniques that allow for rapid assembly while ensuring stability.

Additionally, buildings like The Shard in London showcase how modern design can blend with traditional materials through innovative prefabrication methods. These iconic examples demonstrate that prefabricated steel construction is not just about practicality; it’s also about pushing boundaries and redefining skylines around the globe. PreFab Inc., a leader in this field, continually strives to contribute to such groundbreaking projects by leveraging cutting-edge technology and sustainable practices.

Lessons from Successful Prefabricated Projects

Successful prefabricated projects often share common traits that can serve as valuable lessons for future endeavors in steel construction. First and foremost is collaboration; engaging architects, engineers, and contractors early on can streamline processes and foster creativity. For instance, when PreFab Inc. partnered with local stakeholders on a recent project, they discovered innovative ways to integrate community needs into their designs while optimizing material use.

Another lesson learned is the importance of flexibility during design phases; being adaptable allows teams to pivot quickly when challenges arise or when new technologies emerge that could enhance efficiency or sustainability. Moreover, successful projects emphasize rigorous quality control throughout the fabrication process—ensuring each component meets high standards before arriving at the site can significantly reduce delays during assembly.

Lastly, effective communication plays a crucial role in managing expectations among all parties involved—from clients to subcontractors—ensuring everyone stays aligned toward a common goal: delivering a high-quality structure on time and within budget.

Analyzing the Impact of Steel Construction

The impact of prefabricated steel construction extends beyond individual projects; it influences industry trends and societal norms around building practices as well. One notable trend is sustainability—steel's recyclability makes it an eco-friendly choice compared to other materials traditionally used in construction. As companies like PreFab Inc. prioritize green initiatives in their operations, they set new standards for environmental responsibility within the industry.

Moreover, using prefabricated components speeds up project timelines significantly—a boon for urban areas facing housing shortages or infrastructure challenges due to population growth. This efficiency not only benefits builders but also provides communities with much-needed facilities more rapidly than conventional methods would allow.

Lastly, analyzing these impacts reveals an ongoing evolution within architecture itself; as more architects embrace prefabricated steel construction techniques coupled with innovative designs enabled by technology advancements like BIM (Building Information Modeling), we may witness a shift toward more dynamic urban landscapes that reflect contemporary values of sustainability and efficiency.

Challenges and Future of Prefabricated Steel Construction

The prefabricated steel construction industry is on the brink of transformation, but it faces several challenges that must be addressed to fully realize its potential. From supply chain disruptions to regulatory hurdles, these obstacles can hinder the widespread adoption of steel construction techniques. However, with innovation and collaboration, these challenges can be overcome, paving the way for a more robust future in prefabricated steel.

Overcoming Common Industry Hurdles

One of the most significant hurdles in prefabricated steel construction is the perception that it lacks flexibility. Many stakeholders still view traditional building methods as more adaptable to changes during construction. To combat this notion, companies like PreFab Inc. are investing in modular designs that allow for easy modifications without compromising structural integrity.

Another challenge is ensuring quality control throughout the fabrication process. Variability in material quality can lead to safety issues or increased costs down the line. By implementing rigorous standards and utilizing advanced technologies such as automated inspections, companies can enhance quality assurance in prefabricated steel components.

Lastly, workforce shortages pose a critical issue for the industry as skilled labor becomes increasingly scarce. As experienced workers retire and fewer young people enter trades, finding qualified personnel becomes challenging. To tackle this problem, initiatives aimed at training and upskilling new workers are essential; PreFab Inc., for instance, actively participates in educational programs that promote careers in prefabricated steel construction.

Future Trends in Steel Construction

Looking ahead, several trends are poised to shape the future of prefabricated steel construction significantly. One notable trend is the integration of smart technology into building designs; this includes IoT devices that monitor structural health and energy usage in real-time. As buildings become smarter through these innovations, they will not only enhance efficiency but also improve occupant comfort.

Sustainability will continue to dominate discussions around future projects as environmental concerns grow more pressing globally. Expect an increase in demand for eco-friendly materials and practices within prefabricated steel construction processes—think recycled materials or energy-efficient production methods that reduce carbon footprints while maintaining performance standards.

Moreover, globalization will play a crucial role as markets expand beyond local borders; this means more opportunities for collaboration between international firms specializing in different aspects of prefabrication technology. Companies like PreFab Inc., which already have a strong foothold internationally, will likely lead this charge by fostering partnerships with other innovators across various regions.

PreFab Inc.'s Vision for the Future

At PreFab Inc., we envision a future where prefabricated steel construction becomes synonymous with efficiency and sustainability on a global scale. Our commitment involves not only embracing cutting-edge technologies but also prioritizing environmentally responsible practices throughout our operations—from material sourcing to waste management strategies.

We aim to pioneer advancements such as AI-driven design tools that optimize every aspect of our projects while minimizing resource consumption—because why settle for less when you can do better? Additionally, we plan to expand our training programs further so we can equip tomorrow's workforce with skills tailored specifically towards modern techniques used within prefabricated steel construction.

In conclusion, while challenges exist within this dynamic field today—ranging from perceptions about flexibility to workforce shortages—the future holds immense promise if we tackle these issues head-on together! With visionary companies like PreFab Inc., leading innovations within sustainable practices coupled with smart technologies will undoubtedly transform how we approach building design moving forward.

Conclusion

The world of construction is undergoing a remarkable transformation, largely driven by the rise of prefabricated steel construction. This innovative approach not only streamlines the building process but also enhances efficiency and safety on-site. With companies like PreFab Inc. leading the charge, we are witnessing a shift towards more sustainable and resilient structures that redefine our skylines.

Transforming Construction with Steel

Prefabricated steel construction has revolutionized how we think about building design and execution. By manufacturing components off-site and assembling them on location, projects can be completed more quickly and with fewer disruptions to the surrounding environment. This method allows for greater precision in engineering and design, ultimately resulting in structures that are not only aesthetically pleasing but also structurally sound.

Moreover, as urbanization continues to rise, the need for efficient construction methods becomes ever more critical. Prefabricated steel solutions offer a way to meet this demand while minimizing waste and maximizing resource use. Companies like PreFab Inc. exemplify this shift, utilizing cutting-edge techniques to deliver projects that stand the test of time.

A Sustainable Future with Prefab Steel

Sustainability is at the forefront of modern construction practices, and prefabricated steel construction plays a pivotal role in this movement. The ability to recycle steel means that less material ends up in landfills, contributing to a circular economy where resources are reused rather than discarded. Additionally, advancements in energy-efficient technologies further enhance the sustainability profile of these buildings.

PreFab Inc.'s commitment to green building certifications underscores its dedication to creating environmentally responsible structures that benefit both clients and communities alike. By integrating sustainable practices into every stage of production, from fabrication through installation, they set an example for others in the industry to follow. The future looks bright as we embrace these eco-friendly innovations within prefabricated steel construction.

Embracing Innovations in Building Design

Innovation is key to staying ahead in any industry, particularly in construction where technology evolves rapidly. The integration of Building Information Modeling (BIM) into prefabricated steel construction allows for enhanced collaboration among architects, engineers, and contractors throughout all phases of a project. This level of synergy ensures that potential issues are identified early on—saving time and reducing costs.

Furthermore, technologies such as 3D printing are beginning to make waves within this sector by enabling rapid prototyping of complex designs using steel materials. As leaders like Autodesk and Tekla continue pushing boundaries with their software solutions tailored for prefabrication processes, we can expect even greater advancements ahead. Embracing these innovations will ensure that companies like PreFab Inc., along with their peers across the globe remain competitive while delivering high-quality builds.