Introduction

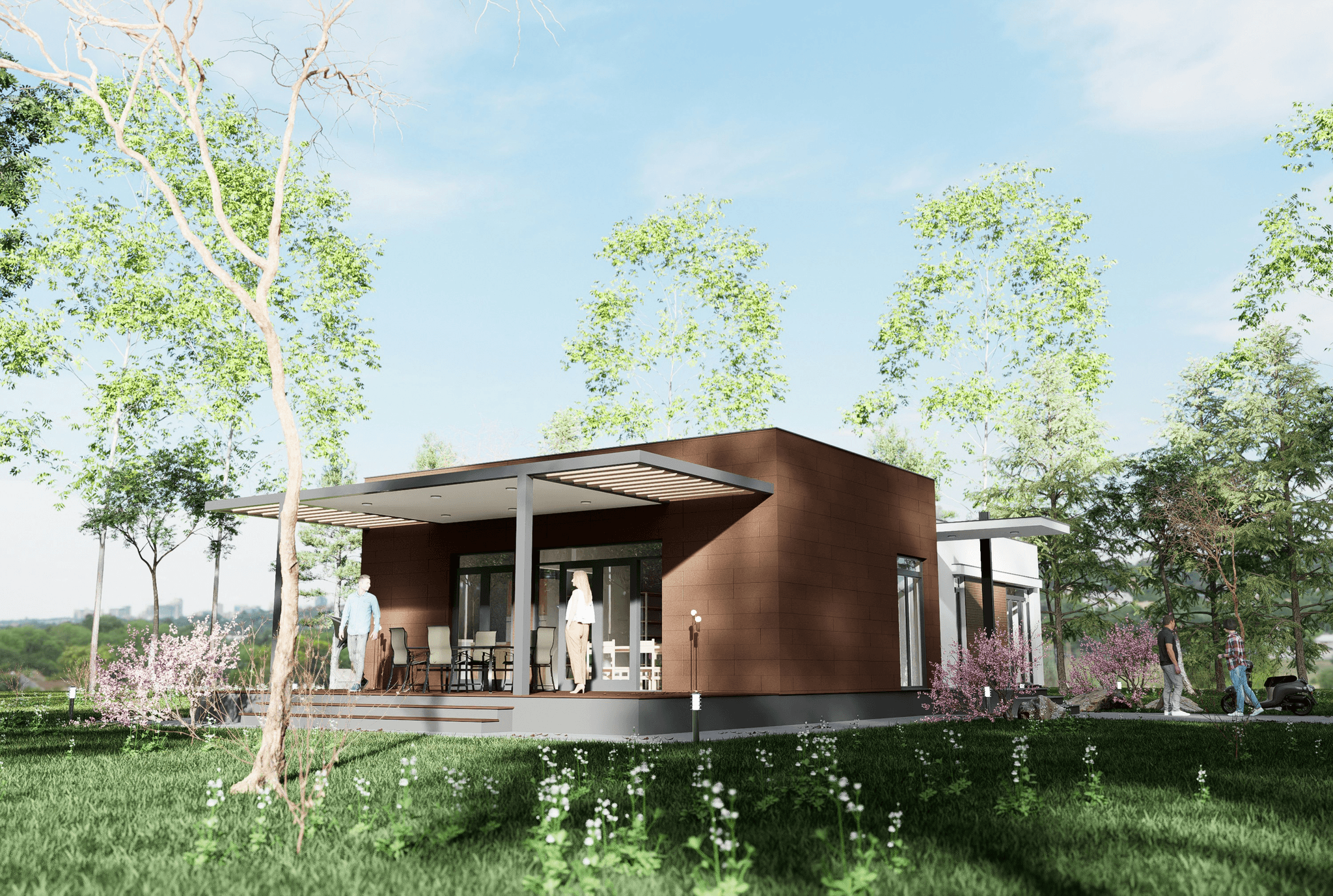

Prefab house installation is revolutionizing the construction landscape, offering a fresh approach to building homes with efficiency and style. As more homeowners and builders recognize the advantages of this method, understanding the intricacies of prefab house installation becomes essential. With companies like PreFab Inc. leading the charge, it's crucial to explore how rapid installation can meet modern housing demands.

Understanding Prefab House Installation

Prefab house installation involves assembling pre-manufactured components on-site to create a complete home. This process typically includes modules or panels that are constructed in a factory setting, minimizing time spent on-site and reducing waste. By grasping the fundamentals of prefab house installation, stakeholders can better appreciate its benefits and challenges.

Benefits of Rapid Installation

One of the standout advantages of prefab house installation is its speed; homes can be completed in a fraction of the time compared to traditional construction methods. This rapid turnaround not only saves builders money but also allows homeowners to move into their new spaces sooner than expected. Additionally, efficient installation processes contribute to reduced labor costs and improved project timelines.

Key Factors Influencing Installation Speed

Several factors influence how quickly a prefab house can be installed, including site preparation, transportation logistics, and assembly techniques. Proper planning ensures that all elements are ready for swift execution when components arrive on-site. By focusing on these key aspects, companies like PreFab Inc. can optimize their processes for faster results in prefab house installation.

Planning and Preparation

When it comes to prefab house installation, meticulous planning and preparation can make all the difference between a smooth assembly process and a chaotic scramble. A well-structured approach not only saves time but also ensures that your project meets all necessary regulations and standards. With the right groundwork laid out, you'll be on your way to enjoying your new home sooner than you think.

Importance of Site Assessment

Before diving into prefab house installation, a thorough site assessment is crucial. This involves evaluating the land's topography, soil quality, and accessibility for transport vehicles—essential factors that can significantly influence the speed of installation. PreFab Inc. emphasizes that understanding these elements helps in anticipating challenges and ensuring optimal placement for your new home.

Moreover, conducting a site assessment allows you to determine any additional preparations needed before assembly begins—like grading the land or clearing obstacles. This proactive approach minimizes unexpected delays during installation and helps keep everything on track. Ultimately, a comprehensive site evaluation sets the stage for efficient prefab house installation.

Securing Necessary Permits

Navigating the maze of permits can feel daunting, but it's an essential step in any prefab house installation project. Depending on your location, you may need various permits related to zoning laws, building codes, or environmental regulations—each designed to ensure safety and compliance with local standards. PreFab Inc. recommends starting this process early since obtaining permits can sometimes take longer than expected.

Once you've identified which permits are required, it's wise to engage with local authorities or consult professionals who understand the ins-and-outs of permit acquisition in your area. This will not only streamline your efforts but also help avoid potential legal pitfalls down the line. Securing these necessary permits is just another piece of the puzzle that leads to successful prefab house installation.

Creating a Detailed Timeline

A detailed timeline serves as a roadmap for anyone involved in prefab house installation; it outlines each phase of construction from start to finish while allowing for flexibility where needed. By breaking down tasks into manageable segments—like site preparation, delivery scheduling, and assembly—you'll have a clearer picture of how long each step might take and what resources are required at each stage.

PreFab Inc.'s experience shows that setting realistic deadlines fosters accountability among team members while keeping everyone focused on their responsibilities during installation week (or weeks). Additionally, including buffer time for unforeseen delays ensures you're not left scrambling if something goes awry—because let's face it: things rarely go exactly as planned!

In conclusion, investing time in planning and preparation is vital for anyone looking at prefab house installation seriously; you’ll thank yourself later when everything runs smoothly! With careful attention paid to site assessments, securing permits promptly, and crafting an effective timeline—all backed by PreFab Inc.'s expertise—you'll be well-equipped for success.

Choosing the Right Prefab Manufacturer

When it comes to prefab house installation, selecting the right manufacturer is crucial for ensuring a smooth process from start to finish. The quality of materials, design options, and overall support can vary significantly between brands. Therefore, taking the time to evaluate leading manufacturers can make all the difference in your project's success.

Evaluating Leading Brands

In the world of prefab house installation, not all manufacturers are created equal. A thorough evaluation includes looking at customer reviews, company reputation, and product offerings. Brands like PreFab Inc., known for their innovative designs and commitment to sustainability, often stand out as industry leaders that prioritize customer satisfaction and quality.

Another important factor is the range of customization options available; some manufacturers offer a more extensive selection than others. Additionally, consider their experience in delivering projects similar to yours—this can give you insight into their reliability and expertise in prefab house installation. Ultimately, making an informed choice will lead you to a manufacturer who aligns with your vision and needs.

Case Study: Blu Homes

Blu Homes serves as an exemplary case study in the realm of prefab house installation. Known for their modern designs and eco-friendly practices, they have carved out a niche that appeals to environmentally conscious homeowners. Their streamlined construction process not only reduces waste but also shortens installation timelines significantly.

Moreover, Blu Homes emphasizes innovation through technology; they utilize advanced building techniques that enhance structural integrity while keeping costs manageable. This approach has earned them accolades within the industry and among clients who appreciate both aesthetics and functionality in their homes. If you're considering prefab house installation with a focus on sustainability and modern design, Blu Homes is certainly worth exploring.

Understanding Warranty and Support

Warranty and support are critical components when choosing a prefab manufacturer for your home project. A robust warranty ensures peace of mind regarding structural integrity over time—after all, no one wants surprises after moving into their new home! Manufacturers like PreFab Inc. often provide comprehensive warranties that cover various aspects of construction.

Additionally, understanding what kind of support you can expect during the installation phase is equally important. Does the manufacturer offer training for your crew? Will they assist with troubleshooting any issues that arise? These questions will help clarify how much assistance you'll receive during your prefab house installation journey.

Efficient Transportation Logistics

Efficient transportation logistics are vital to successful prefab house installation, ensuring that components arrive on-site in a timely and organized manner. The right logistics strategy can significantly reduce delays and help streamline the entire assembly process. By implementing best practices, utilizing local resources, and minimizing travel time for components, companies like PreFab Inc. can enhance their overall project efficiency.

Best Practices for Delivery Coordination

Effective delivery coordination is the backbone of any successful prefab house installation project. Start by establishing clear communication channels among all stakeholders involved, including suppliers, transporters, and the on-site crew. Utilizing a centralized scheduling system can help track deliveries in real-time, allowing you to anticipate any potential hiccups and adjust your plans accordingly.

Moreover, it’s essential to create a detailed checklist of all components needed for installation before they leave the manufacturer’s facility. This ensures that nothing is left behind or forgotten during transit. By planning ahead and coordinating deliveries meticulously, you can keep your project timeline intact and avoid costly delays.

Utilizing Local Transport Services

When it comes to prefab house installation, leveraging local transport services can be a game changer in terms of efficiency and cost-effectiveness. Local providers often have better knowledge of regional routes and traffic patterns than larger national carriers, which can lead to faster delivery times for your prefab components. Plus, using nearby services helps minimize transportation costs while supporting local businesses—talk about a win-win!

Additionally, local transport services may offer more flexible scheduling options compared to larger companies with rigid timelines. This flexibility allows you to adapt quickly if there are changes in your project schedule or unexpected delays at the site. With PreFab Inc.'s commitment to efficient logistics practices, partnering with local transport providers becomes an integral part of ensuring smooth installations.

Reducing Travel Time for Components

Reducing travel time for components is crucial when aiming for rapid prefab house installation without compromising quality or safety standards. One effective strategy is to source materials from manufacturers that are geographically closer to your construction site; this not only shortens delivery times but also minimizes fuel consumption—good news for both budgets and the environment!

Another approach involves optimizing routes based on real-time traffic data; using technology like GPS tracking systems can help identify faster paths while avoiding potential roadblocks or delays caused by construction or accidents along the way. Moreover, coordinating multiple deliveries into one trip whenever possible reduces overall travel time significantly—less time on the road means more time focused on getting that dream home assembled!

In conclusion, efficient transportation logistics are paramount in ensuring that every aspect of prefab house installation runs smoothly from start to finish. By following best practices for delivery coordination, utilizing local transport services effectively, and reducing travel times wherever feasible, companies like PreFab Inc. set themselves up for success in this rapidly evolving industry.

On-Site Assembly Techniques

When it comes to prefab house installation, the on-site assembly process is where the magic truly happens. This phase transforms pre-manufactured components into a livable structure, and streamlining this process can significantly reduce installation time. By focusing on efficient techniques, teams can ensure that every aspect of assembly is executed with precision and speed.

Streamlining the Construction Process

To streamline the construction process during prefab house installation, it's crucial to establish clear workflows and roles for each team member. This means having a well-defined plan that outlines tasks from unloading materials to final inspections, reducing bottlenecks and confusion. Additionally, employing modular construction methods allows for parallel workstreams; while one section is being assembled, others can be prepared simultaneously.

Effective communication plays a vital role in this streamlined approach. Utilizing walkie-talkies or project management apps ensures that everyone stays on the same page regarding progress and any potential issues that arise during assembly. With PreFab Inc.’s commitment to innovation, integrating these tools will not only enhance coordination but also foster a collaborative environment among your crew.

Tools and Technology to Accelerate Assembly

In today's fast-paced world of prefab house installation, leveraging advanced tools and technology can make a significant difference in assembly speed and accuracy. From drones for site surveying to laser levels ensuring perfect alignment, these technologies help eliminate human error while expediting processes. Moreover, using power tools designed specifically for prefab components reduces manual labor time significantly.

Investing in software solutions that allow real-time tracking of materials and progress also enhances efficiency. For instance, PreFab Inc.’s proprietary software provides updates on delivery schedules or inventory levels directly to your team’s devices—no more waiting around for missing pieces! By combining cutting-edge tools with traditional craftsmanship, you’ll create an assembly line that rivals even the most efficient factories.

Training Your Installation Crew

No matter how advanced your technology or streamlined your processes are, nothing beats having a well-trained crew when it comes to prefab house installation. Regular training sessions focusing on specific techniques related to prefabricated structures are essential; this ensures that everyone understands their roles thoroughly before they even step foot on-site. Furthermore, incorporating hands-on workshops allows crews to familiarize themselves with new tools or methods before deployment.

At PreFab Inc., we believe in investing in our people as much as our products; thus providing ongoing education not only enhances skills but also boosts morale among workers who feel valued and empowered in their roles. A knowledgeable crew is more likely to identify potential issues early on—saving time and resources down the line while maintaining high-quality standards throughout the project.

Lastly, fostering an environment of continuous learning encourages innovation within your team; they may come up with new ideas or techniques that could further streamline future installations! Remember: a well-trained crew isn’t just an asset—it’s the backbone of successful prefab house installation projects.

Quality Control During Installation

Quality control is paramount during prefab house installation, ensuring that every component fits together seamlessly and meets safety standards. This phase can make or break the structural integrity of your new home, so it’s essential to implement effective quality control measures. After all, a well-installed prefab house not only looks great but is also built to withstand the test of time.

Ensuring Structural Integrity

To ensure structural integrity during prefab house installation, it's crucial to adhere to the manufacturer’s specifications and guidelines. Each component of a prefab home is engineered for optimal performance; thus, following these directives helps avoid potential pitfalls down the line. Regular checks on the foundation and load-bearing elements are also vital—after all, nobody wants their dream home to turn into a structural nightmare!

Conducting Regular Inspections

Regular inspections throughout the installation process are key to maintaining high-quality standards in your prefab house project. Designate specific milestones where inspections take place—think of it as quality checkpoints along your journey toward a completed home. By catching any discrepancies early on, you can save time and money while ensuring that your new abode meets all safety regulations.

Collaborating with PreFab Inc. for Quality Assurance

Partnering with PreFab Inc. during your prefab house installation guarantees an extra layer of quality assurance that simply can't be overlooked. Our team offers expert insights and guidance throughout the construction process, helping you identify potential issues before they escalate into major concerns. By collaborating closely with us, you’ll not only streamline your installation but also elevate its overall quality—because at PreFab Inc., we believe that every detail counts!

Conclusion

In wrapping up our exploration of prefab house installation, it’s clear that this method of building is not just a trend but a transformative approach to home construction. As we look ahead, the innovative trends and technologies in prefab housing are set to redefine how we think about residential spaces. With companies like PreFab Inc., the future of prefab house installation promises to be faster, more efficient, and environmentally friendly.

Innovative Trends in Prefab Housing

The landscape of prefab housing is continuously evolving, with exciting innovations emerging at every turn. From sustainable materials to smart home technology integration, these trends are making prefab house installation not only more appealing but also more practical for modern living. PreFab Inc. is at the forefront of these advancements, offering homes that are energy-efficient and equipped with cutting-edge features that enhance comfort and convenience.

Future of Prefab House Installation

Looking into the future, prefab house installation will likely embrace even greater customization options and improved manufacturing techniques. The demand for quick and efficient housing solutions will drive companies like PreFab Inc. to innovate further, ensuring homes can be tailored to individual needs without sacrificing quality or speed. As urbanization continues and housing shortages become more pressing, the role of prefab houses will only grow in importance as a viable solution for communities worldwide.

Ensuring Longevity Through Maintenance

While rapid installation is a significant advantage of prefab houses, ensuring their longevity hinges on regular maintenance practices post-installation. Homeowners must stay proactive about upkeep to protect their investment; this includes routine inspections and addressing any potential issues promptly. Partnering with PreFab Inc., clients can access valuable resources and support for maintaining their homes effectively long after the initial prefab house installation is complete.