Introduction

In the ever-evolving landscape of construction, prefabricated building systems are emerging as a game-changer. These innovative methods not only streamline the building process but also respond to modern demands for efficiency and sustainability. Companies like PreFab Inc. are leading the charge in this shift towards contemporary construction techniques that prioritize speed, cost-effectiveness, and environmental responsibility.

Understanding Prefabricated Building Systems

Prefabricated building systems involve assembling components of a structure in a controlled factory environment before transporting them to the construction site for quick assembly. This approach contrasts sharply with traditional construction methods that often face delays due to weather or labor shortages. By utilizing prefabrication, builders can ensure higher quality control while significantly reducing on-site waste.

The Shift Towards Modern Construction

The construction industry is experiencing a notable shift towards modern methodologies that embrace technology and innovation, including prefabricated building systems. As urbanization accelerates and housing demands rise, traditional building methods struggle to keep pace with these challenges. Prefabrication offers a viable solution by delivering structures faster and more efficiently than ever before, allowing companies like PreFab Inc. to meet market needs head-on.

Why Prefabrication Matters Today

Today’s focus on sustainability and efficiency makes prefabricated building systems more relevant than ever. They not only reduce construction time but also minimize environmental impact through better resource management and energy efficiency practices. As we look toward the future of affordable housing solutions, embracing prefabrication could be key to addressing both economic and ecological concerns in our communities.

Speed of Construction

In the fast-paced world of construction, speed is often a game-changer. Prefabricated building systems are designed to significantly reduce the time it takes to bring a project from concept to completion. This efficiency not only accelerates timelines but also allows developers and contractors to meet tight deadlines without sacrificing quality.

Reduced Build Time Benefits

One of the standout advantages of prefabricated building systems is their ability to minimize build time dramatically. Traditional construction methods can be bogged down by weather delays, labor shortages, and unforeseen complications on-site. In contrast, with prefabrication, much of the work occurs in a controlled factory environment, allowing for simultaneous site preparation and module production—resulting in faster overall project delivery.

Moreover, reduced build times lead to quicker occupancy dates for clients and less financial strain on developers who can begin generating revenue sooner. By embracing these modern techniques, companies like PreFab Inc. have successfully demonstrated that speed doesn’t mean compromising quality; it simply means working smarter.

Faster Project Turnarounds

Faster project turnarounds are crucial in today’s competitive market where every day counts. Prefabricated building systems streamline processes through efficient planning and execution that traditional methods struggle to match. This agility allows projects to adapt quickly as needs change or new challenges arise—keeping everything on track.

Additionally, quicker turnarounds can lead to lower financing costs since projects require less time before they start generating income or serving their intended purpose. With PreFab Inc., clients often report being able to move into their newly constructed spaces months ahead of schedule compared to conventional builds—making a significant impact on their operational efficiency.

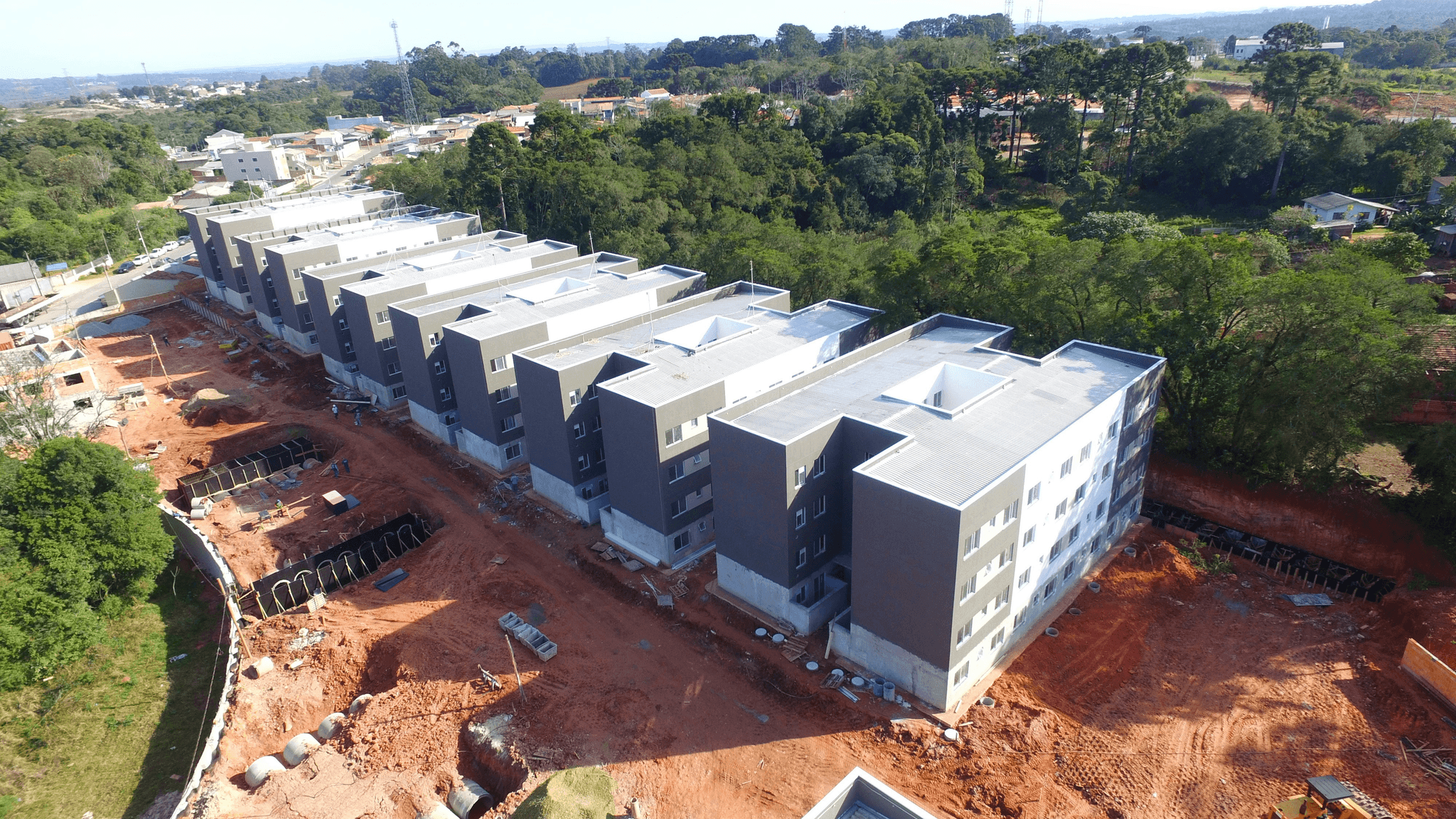

Case Study: PreFab Inc. Time Savings

To illustrate the time-saving prowess of prefabricated building systems, let’s look at a recent project by PreFab Inc., which involved constructing a modular office complex for a tech startup in just four months—half the typical timeline for such developments! By utilizing advanced manufacturing techniques and precise logistical planning, each module was crafted off-site while foundation work commenced simultaneously at the location.

This dual approach allowed PreFab Inc. not only to meet but exceed client expectations regarding delivery timelines while ensuring high standards throughout the process. The successful completion within this compressed timeframe demonstrates how prefabrication can revolutionize construction schedules—making it an attractive option for businesses eager for rapid expansion or renovation projects.

Cost Efficiency

In the world of construction, cost efficiency is a game-changer. Prefabricated building systems have emerged as budget-friendly solutions that not only save money but also offer high-quality results. By streamlining the construction process, these systems allow builders to allocate resources more effectively, making projects financially viable without compromising on quality.

Budget-Friendly Construction Solutions

When it comes to construction budgets, prefabricated building systems are like a breath of fresh air. These systems significantly reduce material waste and minimize on-site labor costs, leading to substantial savings for developers and homeowners alike. With PreFab Inc.'s innovative designs, clients can enjoy modern aesthetics while keeping their wallets happy—it's a win-win situation!

Moreover, the predictability of costs associated with prefabrication means fewer unexpected expenses during construction. This financial clarity allows project managers to plan more effectively and avoid those pesky budget overruns that often plague traditional building methods. In short, choosing prefabricated solutions can be a smart move for anyone looking to build without breaking the bank.

Lower Labor Costs Explained

One of the most compelling advantages of prefabricated building systems is their ability to lower labor costs substantially. Since many components are manufactured off-site in controlled environments, there’s less need for extensive on-site labor—meaning fewer workers are required during critical phases of construction. This reduced labor demand translates into significant cost savings for contractors and developers.

Moreover, skilled labor shortages in the construction industry can lead to inflated wages; however, with prefabrication, much of the heavy lifting is done before materials even arrive at the site. PreFab Inc.'s efficient assembly line processes ensure that projects stay on schedule while minimizing reliance on scarce skilled laborers. Ultimately, this not only cuts costs but also accelerates project timelines.

Real-World Example: Prefabricated Success

To illustrate just how effective prefabricated building systems can be in achieving cost efficiency, let’s look at a recent success story from PreFab Inc. A mid-sized residential development project was completed using our innovative modular units that slashed both time and expenses by 30%. The result? Homebuyers moved into their new homes weeks ahead of schedule—all while staying well within budget.

This case highlights how embracing modern techniques in construction can yield impressive financial outcomes without sacrificing quality or design integrity. As more builders recognize these benefits, it's clear that prefabrication isn't just an option; it’s becoming a preferred choice across various sectors within real estate development.

Sustainability and Environmental Impact

In today's world, sustainability is no longer just a buzzword; it's a necessity. Prefabricated building systems have emerged as champions of eco-friendly construction, offering innovative solutions that minimize waste and maximize efficiency. By embracing these practices, companies like PreFab Inc. are paving the way for a greener future in the construction industry.

Eco-Friendly Building Practices

Prefabricated building systems inherently promote eco-friendly practices by reducing material waste during the construction process. Traditional building methods often lead to significant excess materials ending up in landfills, but with prefabrication, components are manufactured in controlled environments where precision minimizes waste. PreFab Inc. exemplifies this approach by utilizing sustainable materials and optimizing designs to ensure minimal environmental impact.

Moreover, the modular nature of prefabricated systems allows for easy disassembly and reuse, further contributing to sustainability efforts. This adaptability means that buildings can be repurposed or relocated without generating unnecessary waste or requiring extensive new resources. By choosing prefabricated solutions from PreFab Inc., clients not only invest in quality structures but also support eco-conscious practices that benefit our planet.

Energy Efficiency in Prefabricated Systems

Energy efficiency is another hallmark of prefabricated building systems that sets them apart from traditional construction methods. These systems often incorporate advanced insulation materials and energy-efficient designs from the get-go, significantly reducing heating and cooling costs for occupants over time. With rising energy prices and increasing awareness of environmental issues, this aspect of prefabrication makes it an attractive option for both homeowners and developers alike.

PreFab Inc.'s commitment to energy-efficient designs ensures that their structures not only meet but exceed current standards for energy performance. By integrating smart technologies such as solar panels and energy-efficient appliances into their prefabricated models, they help clients reduce their overall carbon footprint while enjoying modern conveniences. Investing in such innovative solutions means saving money on utility bills while contributing positively to the environment.

Impact on Carbon Footprint: A Case Study

To illustrate the tangible benefits of prefabricated building systems on carbon footprints, let's take a closer look at a recent project by PreFab Inc., which involved constructing a community center using modular components sourced sustainably. This project demonstrated how utilizing prefabrication reduced greenhouse gas emissions throughout its lifecycle—from manufacturing through transportation to assembly on-site—compared to conventional builds.

By employing local suppliers for materials and streamlining transportation logistics through efficient planning, PreFab Inc.'s community center project achieved a remarkable reduction in its overall carbon footprint—by nearly 30% compared to similar traditional constructions! This case study serves as an inspiring example of how embracing sustainable practices within prefabrication can lead not only to environmentally friendly outcomes but also to significant cost savings over time.

Design Flexibility and Customization

In the realm of construction, one size does not fit all. Prefabricated building systems are revolutionizing the way we approach design by offering tailored solutions that cater to unique needs. Whether it's a compact urban dwelling or an expansive commercial space, these systems can be customized to meet specific requirements without compromising on quality or aesthetics.

Tailored Solutions for Unique Needs

The beauty of prefabricated building systems lies in their inherent adaptability. Clients can work closely with manufacturers like PreFab Inc. to create designs that reflect their vision while ensuring functionality and efficiency. This level of customization allows for adjustments in layout, materials, and finishes, resulting in a structure that is not only practical but also uniquely personal.

Moreover, tailored solutions can address various challenges such as site limitations or specific regulatory requirements. By leveraging advanced technology and modular components, builders can optimize space usage and enhance the overall design appeal. Ultimately, prefabrication provides a canvas where creativity meets practicality, making it an ideal choice for diverse projects.

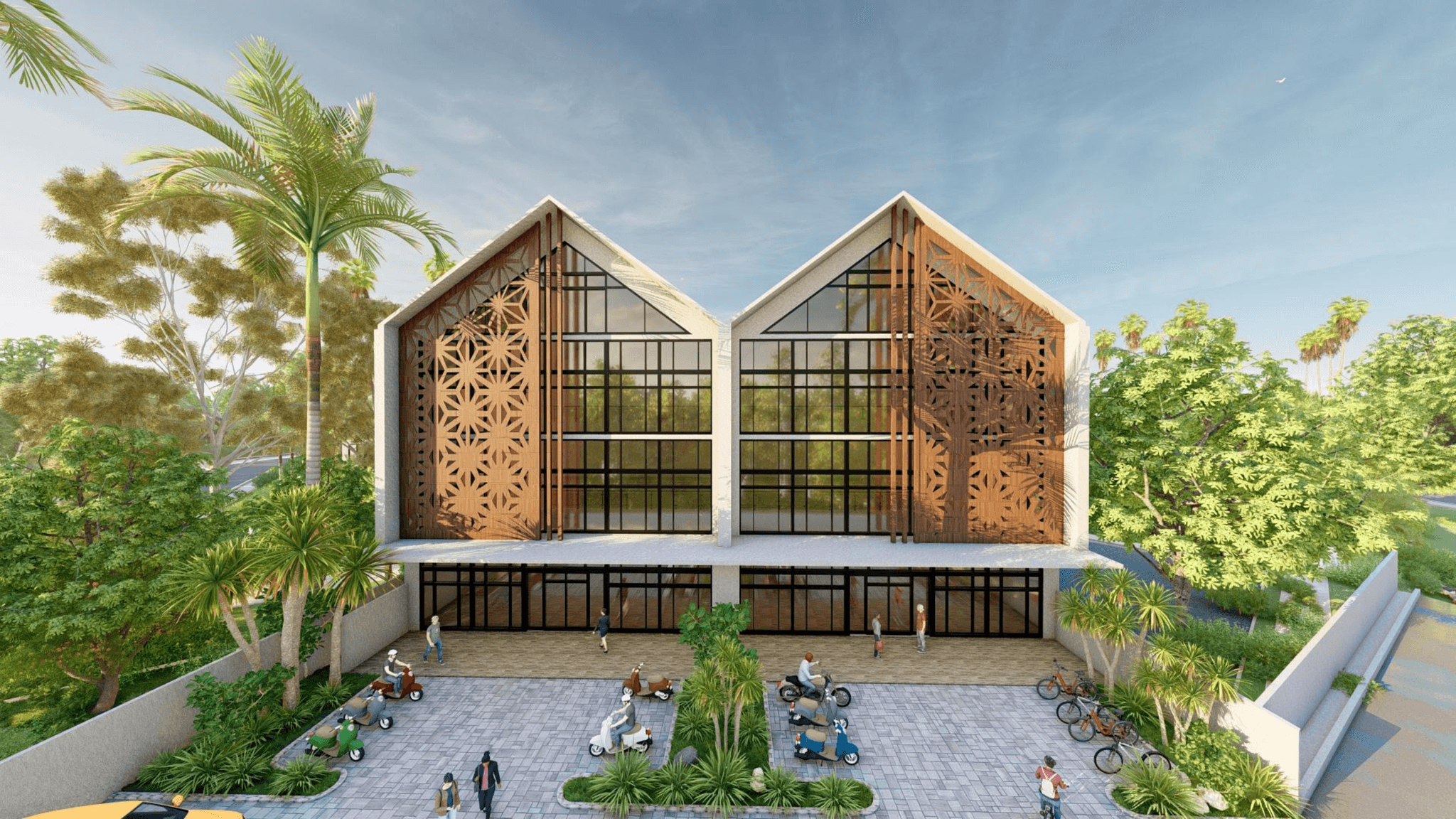

Innovations in Prefabricated Design

Innovation is at the heart of modern prefabricated building systems, pushing the boundaries of what’s possible in construction design. With advancements such as 3D modeling and computer-aided design (CAD), architects and engineers at PreFab Inc. are able to visualize complex structures before they are built. This means potential issues can be identified early on, leading to smoother execution during construction.

Additionally, innovative materials are being utilized within these prefabricated systems to improve energy efficiency and durability while maintaining aesthetic appeal. From sustainable wood composites to high-performance insulation materials, each element is carefully chosen to enhance overall performance without sacrificing style. As a result, clients benefit from cutting-edge designs that stand out while being environmentally friendly.

Showcase: PreFab Inc. Custom Projects

To illustrate the power of customization in prefabricated building systems, let’s take a closer look at some standout projects by PreFab Inc. One notable example is a stunning residential home designed for a family seeking both elegance and sustainability; it features open-concept living spaces made from eco-friendly materials that blend seamlessly with nature.

Another impressive project involved creating modular office spaces for a tech startup looking to expand rapidly without compromising on quality or aesthetics—these units were designed with flexibility in mind so they could be reconfigured as needed over time. Each project reflects how pre-fab innovation translates into real-world success stories where function meets flair.

In conclusion, embracing design flexibility through prefabricated building systems opens up endless possibilities for customized architecture that meets diverse needs while promoting sustainability and efficiency.

Quality Control and Durability

When it comes to prefabricated building systems, quality control is paramount. PreFab Inc. adheres to rigorous manufacturing standards that ensure every component meets the highest benchmarks for safety and durability. This commitment not only enhances the longevity of our structures but also instills confidence in our clients about their investment.

Rigorous Manufacturing Standards

At PreFab Inc., we implement stringent quality assurance protocols throughout the production process of our prefabricated building systems. Each module undergoes comprehensive inspections, from raw materials to final assembly, ensuring that only top-notch components make it into your project. These manufacturing standards are not just a checkbox; they reflect our dedication to delivering buildings that stand the test of time.

Enhanced Longevity of System

One of the standout benefits of prefabricated building systems is their enhanced durability compared to traditional construction methods. With advanced materials and engineering techniques, structures built by PreFab Inc. are designed to endure harsh weather conditions and resist wear over time. This longevity translates into fewer repairs and maintenance costs down the line, making these systems a smart choice for both residential and commercial projects.

Client Testimonials on Quality

Don’t just take our word for it; listen to what our satisfied clients have to say about their experience with PreFab Inc.’s prefabricated building systems! Many have praised the exceptional quality and durability they’ve experienced since moving into their new spaces, emphasizing how these buildings exceed their expectations in both aesthetics and performance. Our testimonials highlight not only customer satisfaction but also reinforce the value proposition of choosing high-quality prefabricated solutions.

Conclusion

In the ever-evolving landscape of construction, embracing innovation is not just a trend but a necessity. Prefabricated building systems have emerged as a powerful solution to the challenges faced by traditional construction methods. With companies like PreFab Inc. leading the charge, we can see how these systems are revolutionizing our approach to building and design.

Embracing Innovation in Construction

The construction industry is ripe for disruption, and prefabricated building systems are at the forefront of this transformation. By utilizing advanced technologies and streamlined processes, firms like PreFab Inc. are setting new standards for efficiency and quality in construction projects. This innovative approach not only speeds up project timelines but also enhances overall project outcomes, making it an attractive option for builders and clients alike.

The Future of Affordable Housing

As urban populations continue to grow, the demand for affordable housing solutions has never been more pressing. Prefabricated building systems offer a viable pathway to meet this need by reducing costs while maintaining quality standards. With PreFab Inc.'s commitment to creating economical yet stylish living spaces, we can envision a future where affordable housing is accessible without compromising on comfort or design.

Why You Should Consider Prefabricated Options

Choosing prefabricated building systems means opting for speed, cost-efficiency, sustainability, and flexibility—all essential elements in modern construction. Companies like PreFab Inc. provide tailored solutions that cater to diverse needs while ensuring high-quality results every time. If you're considering your next construction project, it's time to embrace prefabrication—it's more than just a trend; it's the future of building.